Durable fibreglass dry freight van truck bodies manufacturer

Composite Box’s fiberglass dry freight van truck bodies have everything you need. The quest for lighter and more durable dry van truck bodies. Adopting the new FRP foam panels, the weight is reduced by at least 200 kilograms. They can replace the traditional aluminum foam sandwich body. For long-distance transportation in different environments, no matter what the road is. With our FRP bodies, your cargo can reach its destination safely.

Our bodies are used in many industries. They chose us over large freight companies, leasing companies, fresh vegetables, and livestock transporters.

We have experts to design the body structure for you. According to your needs, we can increase your productivity and reduce your risk and cost. Whether you are engaged in freight transportation, delivery, or rental with our moving truck box using FRP panels.

We offer kits for the floor, frame, LED light, bumper, loading, side door, rear door, and box body.

Features

Faster, lighter, and more cost-effective.

FRP sandwich panel, as the main panel, is superior to the traditional aluminum truck body structure. Reducing weight and increasing load capacity are the biggest highlights.

- Body is corrosion-resistant, waterproof, and moisture-proof.

- PET core is environmentally friendly and recyclable.

- No rivets; a more beautiful appearance.

- Lightweight, reduce costs and increase efficiency

Get Free Quote of fibreglass dry freight van truck bodies

specificities

Faster, lighter, and more cost-effective.

FRP sandwich panel, as the main panel, is superior to the traditional aluminum truck body structure. Reducing weight and increasing load capacity are the biggest highlights.

- Body is corrosion-resistant, waterproof, and moisture-proof.

- PET core is environmentally friendly and recyclable.

- No rivets; a more beautiful appearance.

- Lightweight, reduce costs and increase efficiency

high quality raw materials

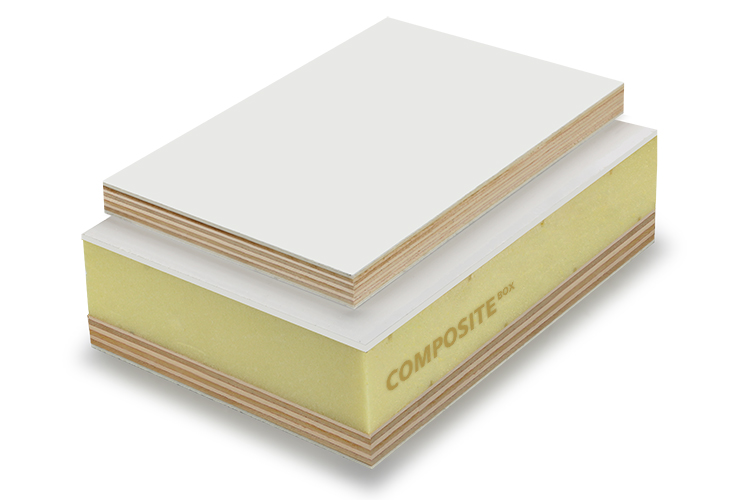

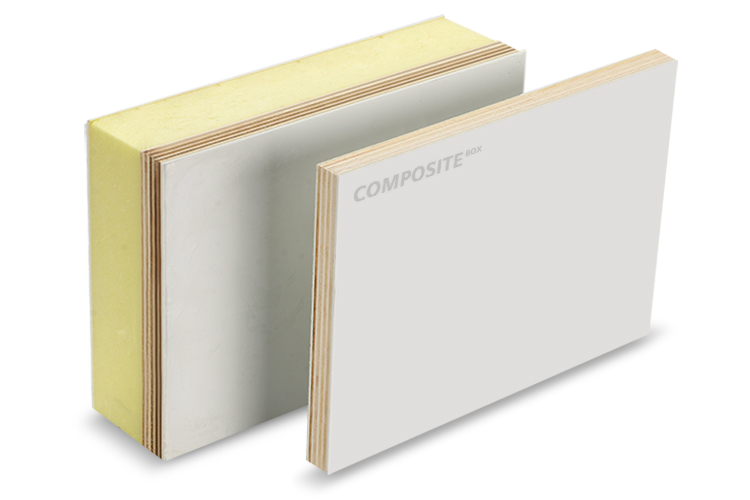

FRP reinforced foam panels as structure. Compared to the earlier aluminum body, they can meet the demand. And has better strength, lower weight, and increased fuel efficiency.

Depending on the performance you need, we have GRP and FRP skins for you to choose from. Foam such as PET, PVC, PU, and XPS can be used for the sandwich layer. There are different performances and internal reinforced structures. They are more stable while being lightweight. Using our van bodies program can reduce the total cost for you.

Customisation options

Our dry freight bodies can be manufactured to existing standards or customized to meet your needs. We use robust and durable materials. Our experts will suggest guidelines and designs for your environment, size, and application.

- Structure: different materials can be chosen as body materials.

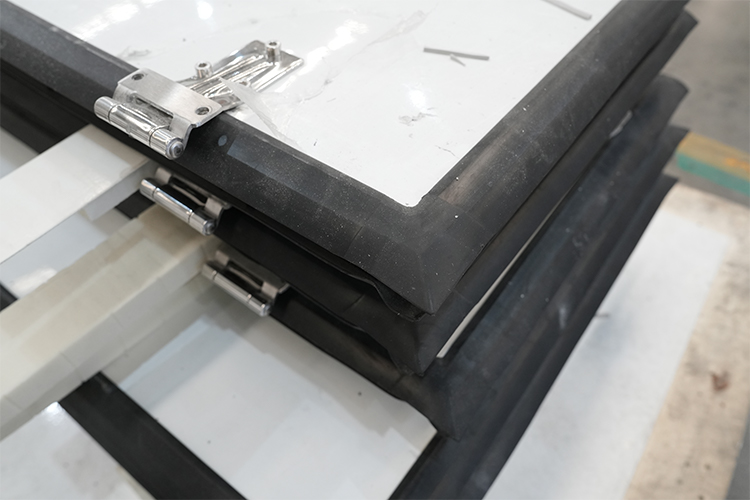

- Front and Rear Doors: Exposed door locking levers and concealed door locking levers are available for dry bulk bodies.

- Exposed Door Locking Lever: The locking lever is on the outside, allowing for a more intuitive view of the condition, locking and unlocking by physical means.

- Hidden door locking lever: better stealth, can prevent illegal invasion, good security performance, and a more beautiful appearance.

- Side and rear frame: A 304 stainless steel door frame is provided to offer more stable support for the box body, with a hidden rivet design, smooth appearance, and no trace of welding.

- Floor: Different shapes and uses, Elevate offers non-slip diamond flooring, hardwood flooring, T-pipe flooring, and rectangular pipe flooring.

- E-track: Various kits are available, using aluminum and galvanized steel materials, which can better fix the cargo and prevent swinging.

- Edge and corner covers: made of aluminum extrusion, are very durable.

Application of Dry freight van truck bodies

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.