What is fiberglass?

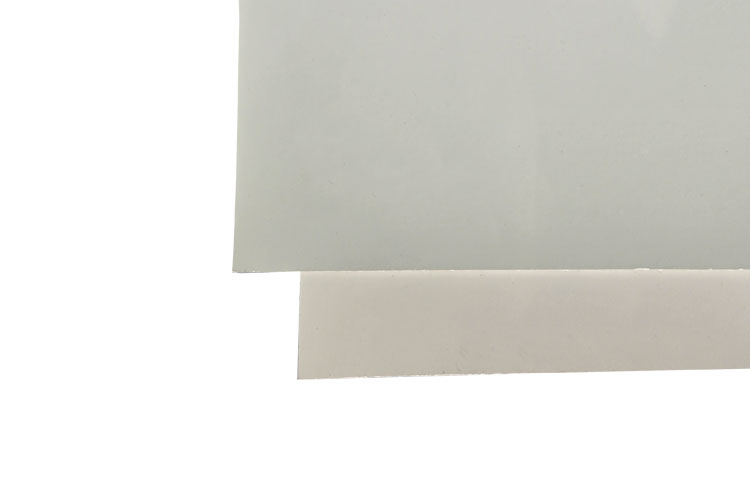

Fiberglass is made by rapidly stretching and cooling molten glass. It is a non-metallic material. It has been used as a raw material for manufacturing since the early 1900s. Fiberglass can also be called glass fiber reinforced plastic. It is a thin sheet that is randomly arranged on a flat surface and can also be woven into fabrics. Different types of fiberglass products can be produced.

Glass fibers are made up of materials such as silica, alumina, calcium oxide and sodium oxide. It is supported by melting at high temperatures, drawing, winding, and weaving. Then, they are bonded together by adhesives, and by combining them with resins, they can be formed into durable composites that can be woven into glass cloth or grit.

Fiberglass has a strong tensile ability, it has an ultimate tensile strength of 3.5 GPa. and has good chemical resistance.

Origin and History of Fiberglass

Fiberglass is a high-performance composite material. Its history can be traced back to around 1500 B.C. The Egyptians used to use fiberglass as decorative items.

In the early 1900s, dale kleist of Owens-Illinois accidentally discovered a way to blow molten glass into fibers, laying the foundation for industrial production. As the next years sunk in, Owens Corning perfected this one technique by combining glass fibers with polyester resins, truly opening a new chapter in manufacturing.

During World War II, fiberglass was used for parts of airplanes, automobiles and boats. This was because of its great durability and resistance to corrosion.

At a later stage with the development of technology, the manufacture of fiberglass has become simpler and the production process has become very easy and is used in all walks of life around the world.

Composition and Manufacturing Process of Glass Fiber

Fiberglass composites are made from a combination of glass fibers and resins, their filaments are usually only 3 to 25 microns in diameter, bonded by polyester, epoxy and vinyl resin.

The raw materials are first melted at temperatures above 1500°C and drawn through a platinum funnel into fine fibers (refer to CTMAT). The surface of the fibers is coated with an impregnating agent (e.g. epoxy emulsion) to enhance the resin bonding. At the forming stage, the fibers are woven into cloth or mat and subsequently bonded to the resin either by hand-layering (hand-applied resin lamination) or by vacuum infusion (resin injection under negative pressure) (refer to VPC Fiberglass). Hand lay-up is suitable for small batch production, while vacuum infusion is used for high-precision, high-volume manufacturing. The curing process is performed using a hot press laminator at high temperatures and pressures (approx. 120°C, 2-5 MPa) resulting in a tight bonding of the layers with a uniform thickness (1.5-50 mm). Finally, the product is cooled, cut and surface-treated to meet the needs of the construction and automotive industries, balancing efficiency and quality.

Different types of glass fibers

Glass fibers can be divided into various types based on cost and performance:

E-glass (general purpose)

F-S-glass (high strength)

A-glass (alkaline glass)

C-glass (chemical resistant)

E-CR (chemical resistance)

M-glass (high modulus of elasticity)

AR-glass (alkali resistant)

According to length, glass fibers can be divided into long, short and continuous fibers.

Long fibers: Long fibers have fiber lengths ranging from several centimeters to meters and have excellent strength and toughness. It can be used to make products like pipes. It has excellent durability.

Short Fibers: Short fibers are measured in microns. They are a little less strong, but are easy to process.

Continuous Fiber: Continuous fiber is a wireless length of glass fiber with high tensile strength.

Properties and Advantages of Glass Fiber

Glass fiber has great physical properties as well as chemical resistance, which makes it one of the more powerful materials in the field of materials. It can be used in everything from lightweight designs, which can reduce the weight of various applications, and provide strong impact resistance and tensile resistance. Fiberglass is suitable for many high-load applications. It is highly corrosion resistant and can withstand acid and alkaline properties well. With water and moisture resistance, it compares favorably to steel and wood. Ideal for truck compartments, RV bodies and more.

Fiberglass can reduce costs, lower than steel and aluminum.

Good durability.

Reduced weight, lightweight.

Fiberglass Application Areas

Fiberglass has a wide range of applications because of its excellent properties and versatility.

Construction industry: It can be used to produce fiberglass composite panels for partition walls, facades and ceilings of houses.

Automotive: It can be used to produce box truck bodies, refrigerated trucks, RV trailers, etc.

Boats: can be used to produce hulls, bulkheads and decks, etc.

Electronic industry: insulating rods, insulating boards, overhead lines, substation equipment, etc.

Sporting goods: pique rackets, golf clubs, tennis rackets, etc.

Household appliances: refrigerators, washing machines, microwave ovens, computers, etc.