Best Refrigerated / Freezer Small Trailer Solution

Professional small refrigerated freezer trailer body best solution supplier

Composite Box specializes in delivering CKD bodies. We also produce small refrigerated and freezer trailers using FRP or CFRT foam panels. We offer a complete solution. Foam cores are XPS or PU, with wall and side panels from 50 mm to 120 mm in thickness. Insulation is excellent.

We can customize power supplies and provide energy-efficient fridges. They last over 10 years. Available in single or multi-temperature options.

We are the best manufacturer of trailer kits. We easily deliver and install them for your refrigerated and freezer trailers, whether you are a trailer dealer or a rental company. A one-stop shop for you.

Customized Size:

We offer small trailers from 2.5 meters to 8 meters in length. Wheels are single axle, dual axle, and triple axle. Lengths range from 2.5 to 6 metres. Capacity can be 7,000 lbs or more and 3,175 kg or more. You can customize any size.

Features

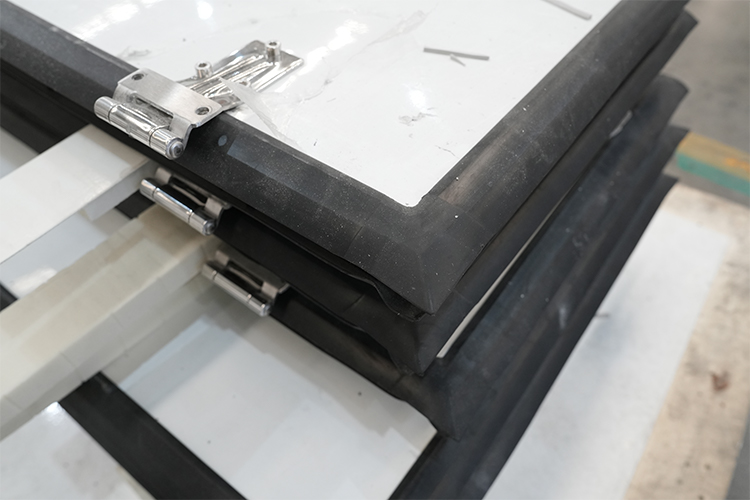

Composite Box ’s small refrigerated trailers use different types of FRP foam panels based on the location. The balanced FRP XPS foam panel structure gives them a long life and great insulation. With the stronger roof and walls, we can keep the temperature at -20℃ to 50℃.

- High quality FRP sandwich panels, T:50-120mm

- Fitted with full size wheels, bearings, guide wheels, galvanised wheel arches

- Wear-resistant brake pads

- Thick rear door

- Internal LED light strip

- Large loading capacity: can hold 2 and more pallets

- Insulation Foam: We make foam boards with PU, XPS for excellent insulation.

- Use of hot-dip galvanized chassis

- Equipped with weighted brackets.

- Independent torsion suspension.

- Lightweight: Lighter than steel or aluminum, thanks to the use of FRP foam panels.

- Long life span (the) life of more than 10 years with proper maintenance.

- Multi-temperature zoning: you can divide the trailer body into many temperature zones.

- Anti-skid floor: Thickened 60 mm anti-skid floor (aluminum alloy + FRP) with skirting board.

- Kit option: our trailer supports customization, with 15+ kit options.

Get Free Quote of refrigerated Small Trailer

product Catalog

contact us

specificities

Composite Box ’s small refrigerated trailers use different types of FRP foam panels based on the location. The balanced FRP XPS foam panel structure gives them a long life and great insulation. With the stronger roof and walls, we can keep the temperature at -20℃ to 50℃.

refrigerated unit

- Category: Refrigeration unit for refrigerated trailers

- Refrigerant: R404A.

- Refrigeration capacity (maximum optional): engine 0 ℃ / 9600 W (-20 ℃ / 5300 W)

- Standby power (maximum optional): 0 ℃ / 8800 W (-20 ℃ / 4840 W)

- Standby battery voltage: AC 380V/50Hz/3PH; AC 220V/60Hz/3PH.

- Unit voltage: DC 12 V.

- Compressor Displacement (Maximum Optional): 466 cc.

- Evaporative air volume (maximum optional): 2,580 m³/h.

- Defrost: Automatic defrost (thermal defrost) and manual forced defrost.

- Optional: remote data recording; remote control function.

Sturdy structure

His production cost will be much higher than the dry van, whether it’s a small or heavy-duty trailer. So, we focus more on the structure and the accessories’ service life. Thus, the shell is very important.

Refrigerated trailers use durable, high-strength fiberglass. It is waterproof, scratch-, dent-, rust-, and corrosion-resistant. It can withstand harsh environments while keeping the trailer’s appearance neat. Our small freezer trailer has the same structure as the large refrigerated one. We will cut no corners.

Strong insulation performance:

We use XPS or PU foam. The panel thickness is 30-120 mm. You can adjust the density and thickness as needed. XPS foam is non-absorbent. Its insulation is second only to PU foam, and it has a higher density. You can keep excellent insulation in -20℃ or 50℃.

Applications

why choose us?

Our fiberglass plywood is specially designed for freight trucks and trailers. It uses a vacuum high-pressure composite process to combine a 1.5 mm fiberglass surface layer with multiple layers of marine-grade plywood, combining the strength of metal with the lightweight advantages of wood. It provides industry-leading moisture resistance, impact strength, and corrosion resistance. At the same time, its standardized modular design supports quick installation and replacement, helping customers reduce maintenance costs by 30%. It is the ideal choice for modern and efficient logistics and transportation.

Parameter table

Different Body Panels

| Attribute | FRP Panels | FRP+CFRT Panels | Galvanized Steel panels | Color Steel Sandwich Panel |

|---|---|---|---|---|

| Outer Material | FRP | Outer: FRP Inner: CFRT (Continuous Fiber Reinforced Thermoplastic) |

Galvanized Steel | Aluminum Alloy |

| Core Material | XPS (Extruded Polystyrene) or PU Foam | XPS or PU Foam | XPS or PU Foam | XPS or PU Foam |

| Advantages |

1. Aesthetic, suitable for high-demand appearance 2. Strong impact resistance, durable 3. UV-resistant, weatherproof 4. Repairable, long service life 5. Perfect match with XPS, PU foam core materials |

1. Strong impact resistance 2. Lower cost, economical and practical 3. CFRT lamination technology provides performance upgrades 4. Suitable for freezer trailer and large-scale applications |

1. Widely used in early applications, mature technology 2. Certain impact resistance |

1. Lightweight, rust-proof 2. Clean and aesthetic appearance 3. Lightweight, suitable for weight-sensitive applications |

Small refrigerated trailer case parameters:

| Specification Details | |

|---|---|

| External Dimensions | 3.5 m (Length) × 1.8 m (Width) × 1.8 m (Height) |

| Internal Dimensions | 3.44 m (Length) × 1.64 m (Width) × 1.63 m (Height) |

| Weight | 146 kg |

| Body Panel | 75mm FRP skin XPS foam core panel |

| Floor Treatment | Diamond-pattern anti-slip aluminum plate |

| Side Door Dimensions | 850 mm (Width) × 1600 mm (Height) × 75 mm (Thickness) |

| Curtain | PVC strip curtain |

| Ceiling Lights | 12/24V multi-voltage LED lights |

| Temperature Zone | Removable soft partition |

| Cooling Unit | Intelligent temperature control system |

Related product

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.