Reefer Truck & trailer Floor Manufacturer

Refrigerated trucks and trailers need insulated floors with the ability to drain water and allow cold air to penetrate. There are a variety of specialised floors for reefer cargo, for semi-truck floors, food trailer floor replacements and more. We support customised services.

You can choose different shapes and designs of floors for semi-trailers and trucks according to the different types of cargo to be transported.

Our floors can increase the cooling efficiency and stabilize the temperature, easy to drain, easy to clean and reduce power consumption. Most importantly, it can make the temperature in the compartment relatively balanced. The use of special structures can greatly improve the efficiency of refrigerated trucks.

Features

COMPOSITE BOX is specialized in the production and manufacture of a wide range of refrigerated truck floors with many advantages. The main advantages are as follows:

- Anti-slip design allows for greater stability of the cargo inside the compartment.

- Grooves underneath the floor allow air to circulate and keep products dry.

- Drainage floor design, moisture drainage, preventing moisture damage to the goods and affecting the insulation effect.

- COMPOSITE BOX is designed with the best thermal insulation and is made of high-strength materials, produced with high-precision stainless steel for excellent corrosion resistance.

Get Free Quote of Reefer Truck & trailer Floor solution

Application

Can be used for truck insulation panels and truck wall panels. Generally used for semi-trailers, small refrigerated trailers, lightweight truck refrigerated body panels, delivery trucks, heavy-duty vans, dry vans, and truck bodies of Exterior wall liner.

Floor Types

Floor Types:

We offer Anti-slip Diamond Aluminum Floor, Rectangular Duct Floors, and T-shaped Floor. and CKD delivery.

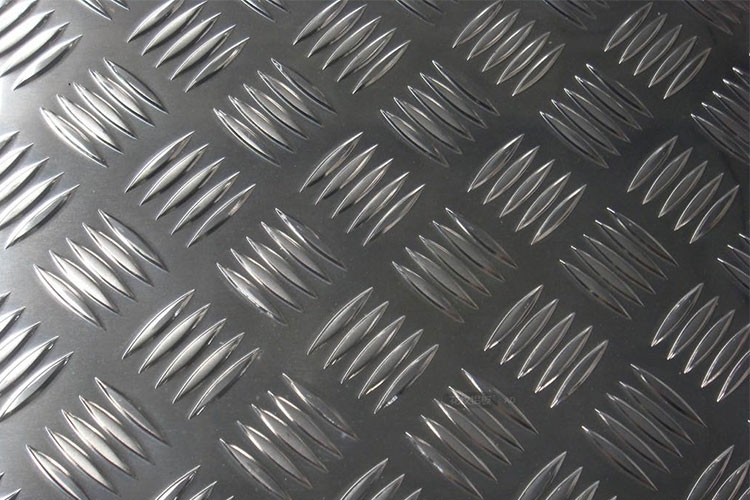

Anti-slip Diamond Aluminum Floor

Based on the results of repeated experiments and surveys of existing products on the market. We finalised the design with the exclusive anti-slip diamond surface, which provides better ground support for the goods in the truck.

The entire floor is made of high-strength aluminum alloy as the raw material. It has undergone aerospace-grade positioning processing, which not only reduces the weight of the truck body but also ensures its excellent pressure-bearing performance under the heavy pressure of cargo. (READ MORE)

Rectangular Duct Floor

The rectangular duct floor uses twice as much raw material as conventional floors, which is very strong and stable.

Every bending angle has been carefully calculated by our designers to achieve the best air circulation effect. At the same time, such a unique structural design can make the work of forklifts more convenient, improve transportation efficiency.

Made of high-strength stainless steel, coupled with the characteristics of the rectangular structure. The entire rectangular duct floor is highly resistant to pressure and wear, and has a long service life.

T-shaped Floor

T-type refrigerated truck floor can greatly enhance the efficiency of air circulation. It is very suitable for transporting goods with high temperature requirements. This design also increases the anti-slip effect of the box floor to ensure that the goods remain stable during transportation.

Laminate Flooring

Laminate flooring is typically composed of materials such as foam, wood, plastic, and stainless steel. Its primary advantages lie in durability, corrosion resistance, and wear resistance. It also offers greater cost savings compared to traditional materials. It is a popular choice in the market.

Aluminum Flooring for Reefer Trucks

Aluminum floors are commonly used in box trucks in wet environments, as well as specifically for transporting pharmaceuticals, meats, and more. It needs to have an anti-bacterial environment. It has the advantages of corrosion resistance, low cost and durability.

FRP Flooring

FRP flooring is also called fibreglass-reinforced plywood flooring. It has strong impact resistance and good thermal insulation. Plywood is used as a core for added strength.

Our durable floors are also suitable for specialised vehicles like the enclosed fiberglass motorcycle trailer, ensuring stable temperature control.

More Floor Types

In addition to the refrigerated floor panels listed above, we also offer reefer floor mats, ribbed floors, grooved floors, and aluminium floors specifically designed for apartment semi-trailers and commercial trucks. We provide customisation services to ensure all your needs are met.

Our fiberglass vans have versatile accessories and kits

Interior trim: the same variety of flooring, T-vent slots, diamond non-slip flooring, honeycomb non-slip flooring, e-track (recessed locking track), meat hooks, kick panels, LED spotlight inside the car, Bumpers, outline lights, reflective tape, etc.

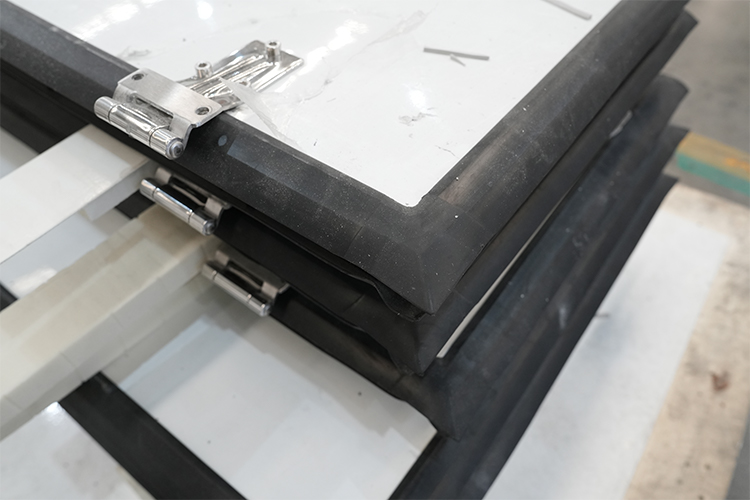

Cooling units, different types of side and rear doors, built-in locks, hinges, and side rails are optional packages available

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.