High Density PVC Board

High-density PVC panels are made from polyvinyl chloride (PVC) and foaming agents. They are excellent structural materials, offering good insulation properties, strength, and versatility. Compared to standard PVC foam panels, high-density PVC panels have a higher density, lower foaming degree, greater hardness, and fewer air pockets. High-density PVC panels are specifically designed for applications such as construction, recreational vehicles (RVs), signage, and racks.

Product Description

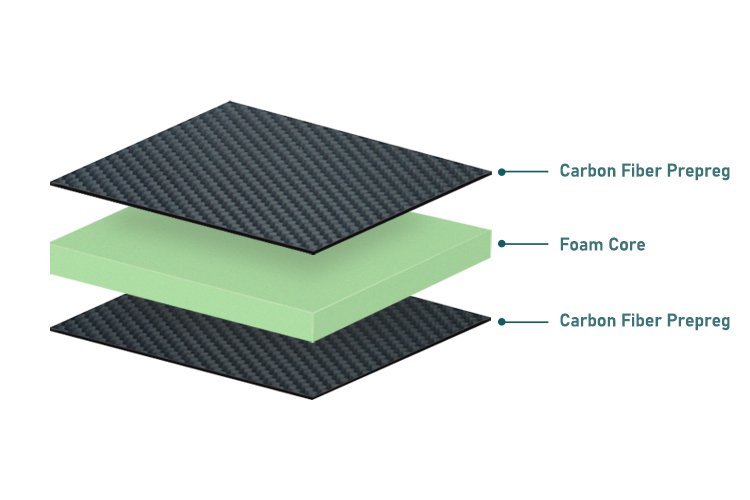

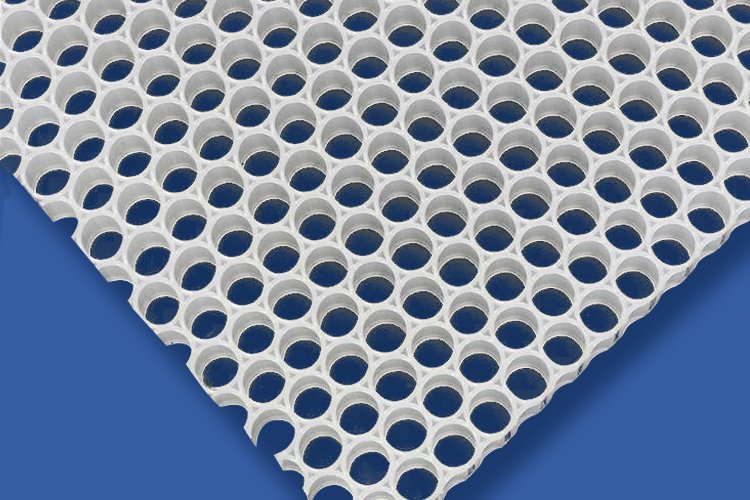

High-density PVC panels are high-performance materials. They offer excellent compression resistance, thermal insulation, and soundproofing capabilities. They also feature waterproof, moisture-resistant, and rot-resistant properties. PVC panels can operate in extreme environments, such as acidic or alkaline conditions. They also provide fire-resistant performance. They are more durable than standard PVC panels. Suitable for CNC machining, cutting, and forming processes, we can accommodate various customization requirements. Additionally, they possess electrical insulation properties. It can effectively replace traditional wooden boards and plywood.

Customization: Composite Box specializes in providing customization services, offering customizable options for different sizes, densities, and surface finishes. Based on your specific application requirements, we will tailor a solution for you. We provide processes such as CNC machining, cutting, milling, printing, lamination, and thermal bending.

Parameter

| Parameter | Value |

|---|---|

| Thickness | 3~50 mm |

| Density | 500~1000 kg/m³ |

| Tensile Strength | 10~25 MPa |

| Flame Retardancy | Self-extinguishing (UL94 V-0 compliant) |

| Electrical Insulation | Volume resistivity ≥ 10¹² Ω·cm |

| Chemical Resistance | Resistant to acids, alkalis and various chemicals |

| Color Options | Black, White, Brown, Gray (Customizable) |

Mechanical Properties Table for High-Density PVC Board

| Property | Value/Description |

|---|---|

| Density | 500~1000 kg/m³ |

| Tensile Strength | 10~25 MPa |

| Compressive Strength | 15~30 MPa |

| Flexural Strength | 20~40 MPa |

| Hardness (Shore D) | 60~80 |

| Impact Strength | 5~15 kJ/m² |

| Heat Deflection Temp. | 60~80°C |

| Electrical Insulation | Volume resistivity ≥ 10¹² Ω·cm |

| Flame Retardancy | Self-extinguishing (UL94 V-0) |

| Water Absorption | ≤ 0.2% |

| Chemical Resistance | Resistant to acids, alkalis and various chemicals |

Get Free Quote of High Density PVC Board

product Catalog

contact us

advantages

- High density: High-density rigid PVC panels offer high strength.

- Thermal insulation: They provide efficient thermal insulation.

- Fire resistance: PVC has flame-retardant properties, helping to prevent the spread of fire.

- Excellent insulation: PVC panels offer good electrical insulation properties.

- Environmentally friendly: PVC panels are recyclable.

- Attractive appearance: They have a smooth surface.

- Easy to process: They can be easily milled, cut, stamped, formed, and painted.

- Durability: Resistant to corrosion from acids, alkalis, and chemicals

- Versatility: Suitable for advertising displays, signage, printing, and furniture panels

Applications

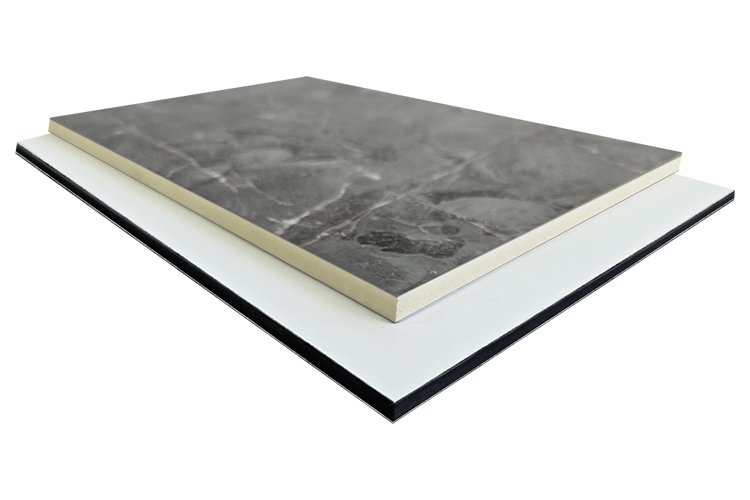

- Advertising printing: signboards, nameplates, printing plates, billboards.

- Furniture: cabinets, furniture boards, decorative boards.

- Construction: decorative strips, structural materials, columns.

- Industry: automobiles, ships, aircraft.

Customization Options for High-Density PVC Sheets

High-density PVC sheets are available in custom sizes: We offer customized thicknesses and dimensions to suit your needs. We can design the appropriate sheet dimensions for your project, regardless of its application.

- Thickness: 3–50 mm, standard thicknesses (0.4 inches, 0.8 inches, 1 inch, 1/8 inch, 1/2 inch, 1/4 inch, 3/16 inch, 3/4 inch, and 3/8 inch)

- Width: 3.6 meters

- Length: 11.8 meters

Surface Treatment: To cater to a wide range of market needs, we have developed various surface treatments and finishes. We offer color customization in black, white, brown, and gray, among others. We also provide different material finishes, such as embossed finishes and vinyl flooring. We strive for both stylish aesthetics and enhanced performance, improving visual appeal and functionality. These finishes not only enhance appearance but also provide anti-slip properties, increase durability, and extend service life.

vedio

FAQ

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.