What are FRP panels used?

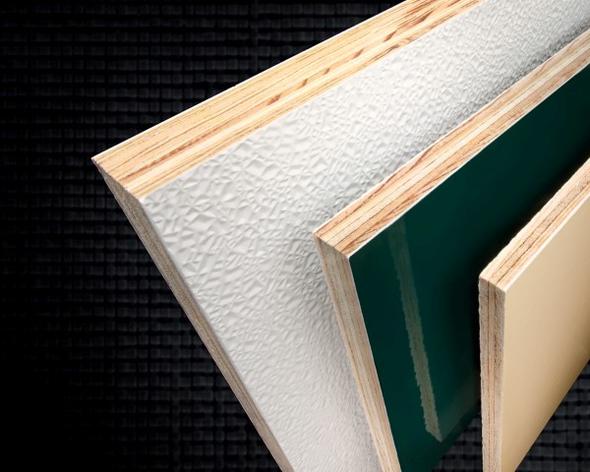

The full name of FRP panels is fiberglass reinforced plastic panels. It is a multi-purpose material and a composite material collectively known as FRP panels. It is also called FRP sandwich. it is a composite material made of glass fibers and a resin matrix, which is usually used in conjunction with other filler materials. Filler materials often include polyurethane foam, plywood, polystyrene foam, and PP honeycomb core.

The reason why FRP panels are so versatile is because of their strong performance. They are lightweight, strong, corrosion-resistant, and water and moisture resistant. It has been the material of choice for a wide range of industries since the 1960s. FRP is useful in many places. You can find it in refrigerated truck bodies, motorhomes, trailers, and building panels. It’s also in hospitals and restaurants, among other places. It can replace traditional materials and solve the problem of rust, bulkiness, and easy rot. FRP panels have been a big trend, bringing protection for the environment. FRP has a long service life, reducing the frequency of replacement and saving more than 30% of materials.

What are the uses of FRP panels?

FRP panels are fiberglass composite panels. They are used in many industries and serve various purposes. The following are the applications in various industries:

Modular Construction

The construction industry is the most common place where FRP panels are used. FRP panels are usually laminated with rigid foam for exterior walls, interior walls, partitions, and ceilings. Modular construction is dominated by the use of FRP panels. It has the advantages of being lightweight, easy to clean, and not leaving stains. One more feature that is highly regarded is that it meets USDA standards. FRP panels with antimicrobial surfaces can be used in food processing plants, where they interact with bacterial cell membranes, nucleic acids, and enzymes through silver ions. Modular structural building panels are easy to install, lightweight, and very popular.

- Schools: The use of FRP panels as building materials in schools can effectively inhibit bacteria and be beneficial to the health of students.

- Supermarkets: they do not absorb dust, are easy to clean, can be kept clean and hygienic, reduce cleaning costs, and have a beautiful appearance.

- Car washes: they are waterproof, do not absorb water, and have a sturdy structure, which prevents mold and mildew and includes other features.

- Hospitals: moisture-proof, anti-bacterial, and other functions can be used in operating rooms, wards, outpatient clinics, and toilets, etc.

Transportation industry and trucks

FRP panels have the advantages of tear resistance, corrosion resistance, and light weight. They can create box truck bodies for refrigerated and dry freight trucks. This material performs well and can cut weight by over 25%. It can replace traditional materials like steel, wood, and aluminum alloy. Improve driving performance and reducing fuel consumption.

- For refrigerated trucks: fiberglass XPS sandwich panels are used for heat insulation and lightweight insulation.

- For dry freight trucks: fiberglass PET sandwich panels are environmentally friendly and lightweight.

- For small enclosed trailers: fiberglass plywood sandwich panels, durable and lightweight.

- For motorhomes: FRP panels are used in motorhome manufacturing for interior walls, floors, and housings to improve fuel efficiency.

Industrial Environment

Industrial settings need materials that resist corrosion. FRP offers better corrosion resistance than steel. Its surface is less prone to rust, which can extend the service life by up to 50%. It is generally used for external protective walls, such as in chemical plants and chemical laboratories.

- Laboratory: anti-corrosive flooring to prevent acidic chemicals from corroding the floor; FRP can enhance the corrosion resistance of the laboratory and reduce maintenance costs.