Aluminum XPS Sandwich Panels

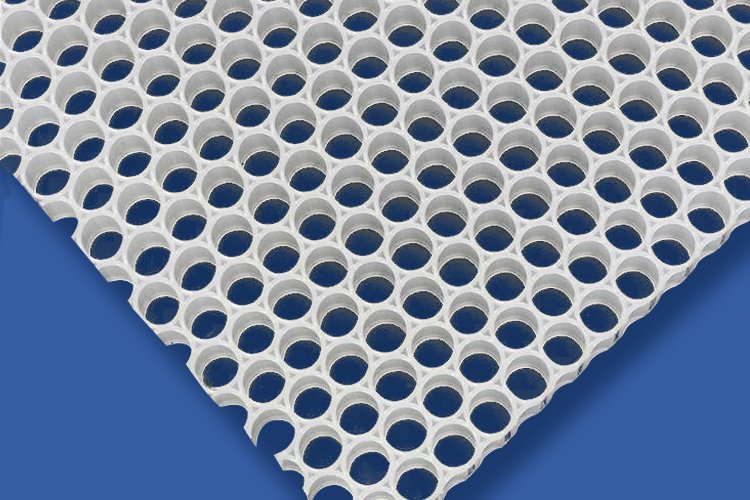

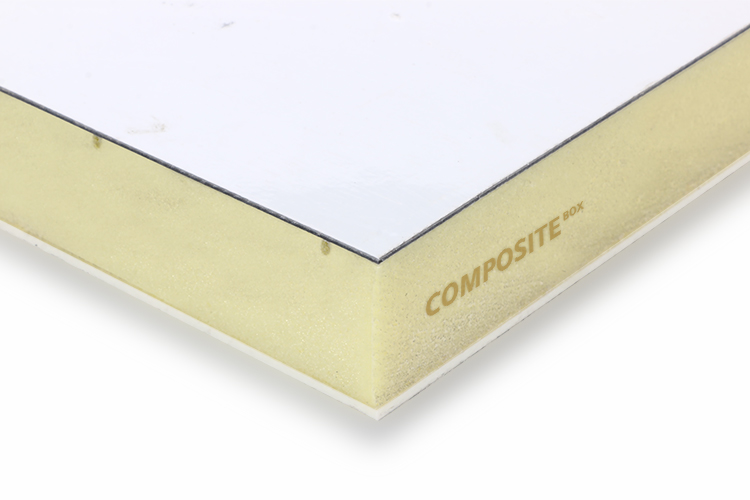

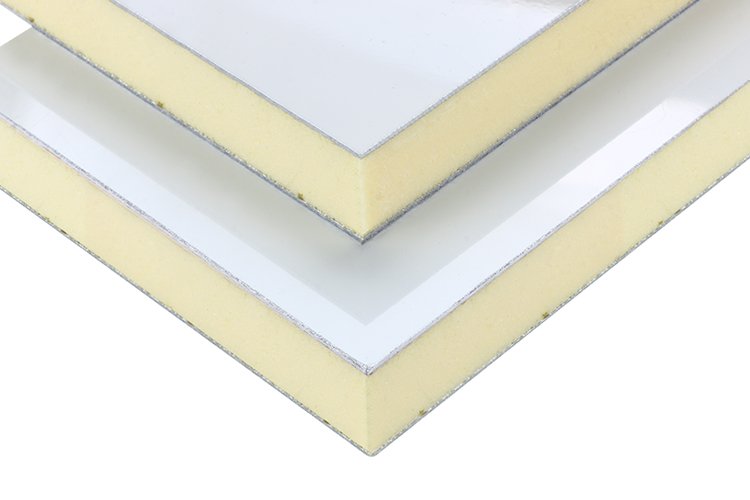

XPS foam board is a high-performance closed-cell rigid foam. It is a high-quality thermal insulation foam board. It adopts an extruded polystyrene structure. It is non-absorbent, moisture-proof, and high-strength, with strong thermal insulation properties. XPS foam board can be laminated with a variety of skins as a high-quality foam core. Composite Box is available in a variety of sizes and supports CNC machining.

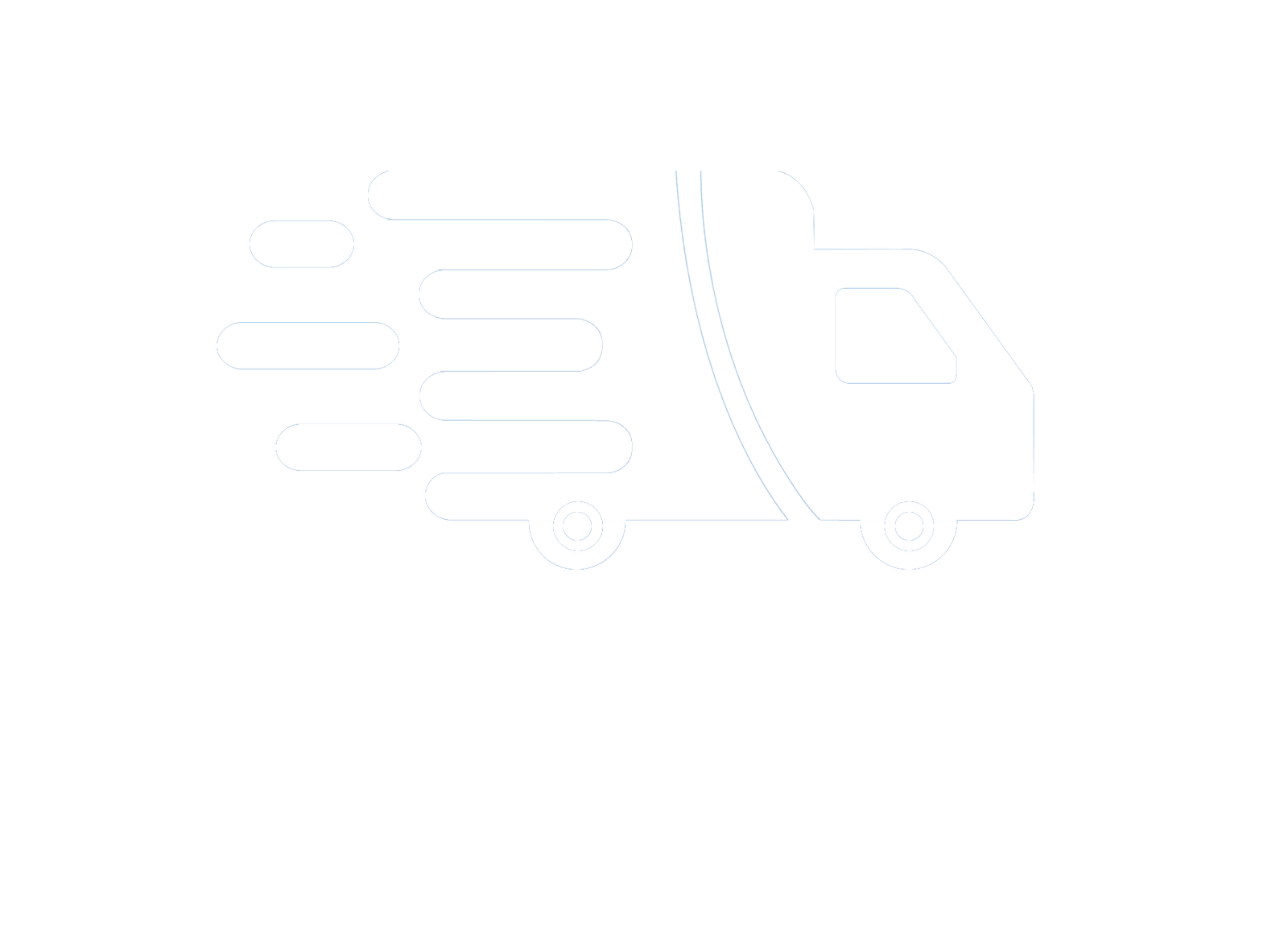

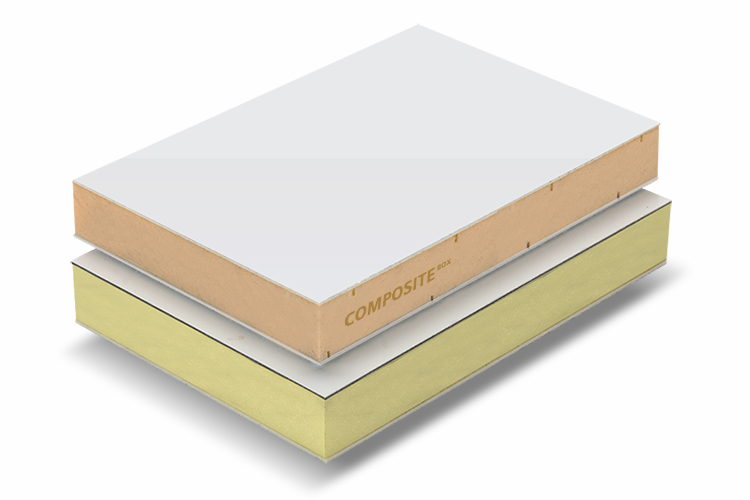

Sandwich Structure

Aluminum alloy XPS sandwich panels are high-performance composite panels composed of an XPS foam core and aluminum sheets, bonded together with high-quality adhesive.

- Aluminum sheets: Corrosion-resistant and durable, with an anodized surface treatment, high hardness, and excellent lightweight properties.

- XPS Core Material (Extruded Polystyrene): The XPS core material is manufactured using a high-density extrusion process, offering excellent thermal insulation properties and low water absorption.

- Adhesive: A polyurethane adhesive is used, which is resistant to cracking and exhibits superior resistance to chemical corrosion.

Get Free Quote of Aluminum XPS Sandwich Panels

product Catalog

contact us

Surface options

parameter table

xps foam board core

| Parameter Name | Data Range |

|---|---|

| Density | 40-60 kg/m³ |

| Thermal Conductivity | 0.020-0.030 W/m·K |

| Compression Resistance | 250-800 kPa |

| Tensile Strength | 600-1200 kPa |

| Water Absorption | <0.3% |

| Dimensional Stability | <1.0% |

| Fire Rating | B0-B1 |

| Operating Temperature Range | -60°C to +80°C |

| Color Options | Gray, Red, Black, Green, etc. |

aluminum sheet

| Parameter Name | Data Range/Options |

|---|---|

| Surface Texture | Color Coating, Mirror Polishing, Textured Brushing, Embossed Imprinting |

| Material Properties | High Machinability, Corrosion and Weather Resistance |

| Alloy Grades | 1060, 1070, 1145, 3005, 3104, 5005, 5154, 6061, 6082, 7075 |

| Surface Treatment | Electrolytic Coloring, Electrostatic Spraying, Embossing, Linear Brushing, Bead Blasting, Mirror Grinding |

| Thickness Range | 0.2-2.5 mm |

| Width Limit | ≤2400 mm |

| Weight Range | 2.5-6.5 kg/m² |

| Durability Lifespan | 20-40 years |

video

applications

Aluminum alloy XPS foam sandwich panels have a wide range of applications.

- Construction: Modular houses, temporary buildings, and exterior wall insulation panels.

- Cold chain transportation: Refrigerated trucks and cold storage wall panels.

- Vehicle manufacturing: RVs and truck bodies.

- Industrial equipment: Equipment housings.

- Interior decoration: Partition walls and ceilings.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.