What is Foam Insulation Panels? What You Need to Know

Foam insulation panels are popular in the wide world. They have been used for many applications. Have you ever used this insulation?

If you’re unsure about insulation materials, this article will help. It focuses on the popularity of foam insulation boards and their benefits. I want to share what they are. This includes their effects, R-value, surface, and pros and cons. I’ll also say if it fits your needs. I will tell you all of these below.

What is foam insulation board?

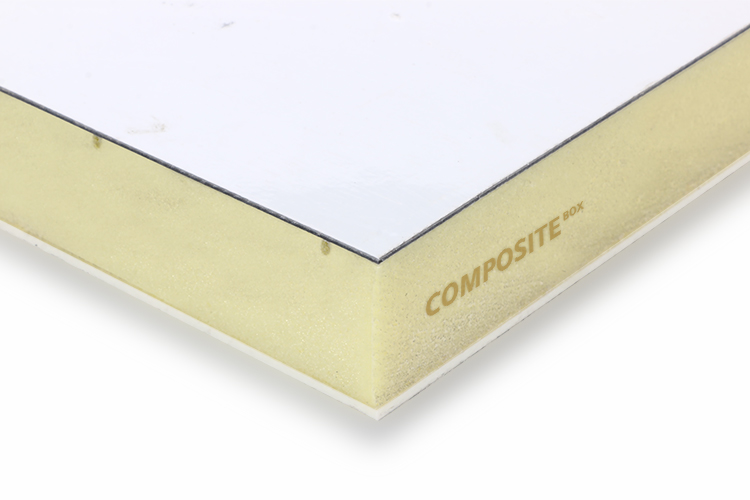

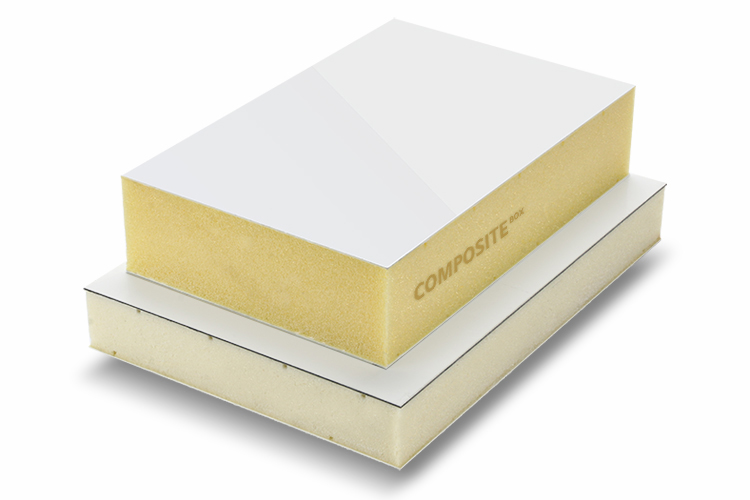

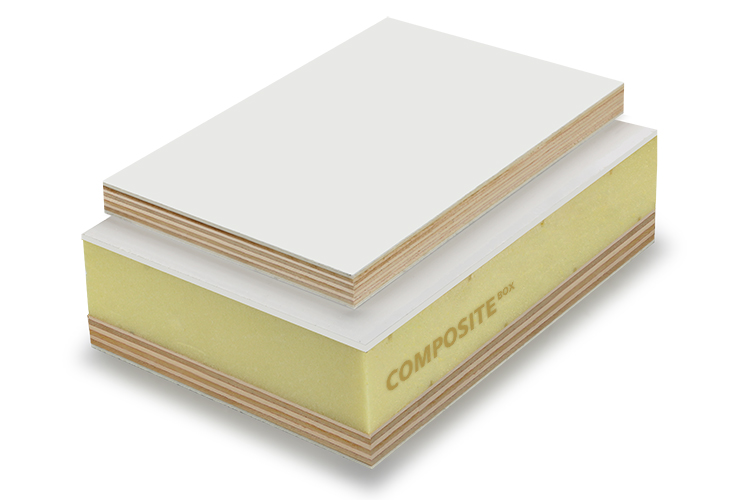

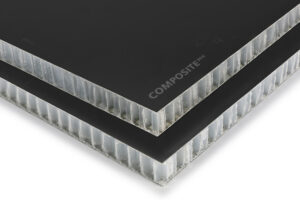

Foam insulation board is made from rigid foam insulation and skins. It is often used in trucks, construction, marine, and aerospace applications. It offers continuous insulation performance (continuous insulation performance refers to the continuous and stable blocking of heat transfer over a long, uninterrupted period of time). It delivers continuous thermal insulation, which stops heat transfer over long periods. This helps maintain steady temperatures. It is also strong, resists compression, and adds acoustic benefits.

Foam insulation panels are often made from XPS, PU, EPS, and polyiso. These materials all offer good thermal insulation. However, they differ in heat resistance and strength. Technically, certain knowledge is required to make the right choice.

What does foam board insulation do?

Foam-insulated sandwich panels serve as insulation and support. They are often used in modular buildings and trucks. They can be manufactured with fewer steps for quick installation. They do not require a lot of steel nails and screws.

It cuts down heat transfer. It also keeps temperature changes steady inside. Plus, it gives strong support, which boosts the structure’s stability.

Because it has a closed-cell structure, it prevents moisture from entering and insulates the exterior from dust. It keeps the interior dry, so it can inhibit the growth of mold and can be used as a complete replacement for wood. Foam board insulation can often be tailored to fit specific dimensions. It comes in various thicknesses, lengths, appearances, densities, and thermal conductivities.

What is the R-value?

R-value is the ability of an insulation material to resist heat flow. It is a scientific parameter. Normally, the lower the R-value, the weaker the insulation, and the higher the R-value, the stronger the insulation. A higher R-value doesn’t always mean that this material is the best choice for you. You should also consider water resistance, strength, and cost when making your decision.

A high R-value allows for better insulation and thermal performance, so if you’re transporting refrigerated goods, it’s a good way to protect against internal temperature imbalances.

So how is the R-value calculated?

The R-value is used to measure the performance of insulation. For a flat sheet, the R-value is calculated as R = d/k, where d is thickness and k is thermal conductivity. For a composite structure with multiple layers, the total R-value adds up the thermal resistance of each layer. The density of the material, along with temperature and humidity, influences thermal conductivity. This, in turn, affects the R-value.

For example, 5 cm thick foam board, thermal conductivity 0.04 W/(m・K), according to R = d/k, the R-value is about 1.25 m²・K/W.

What kind of insulation foam is available?

A good insulating foam needs a high R-value. Some foams also resist moisture and water. Others are very cheap. Then, there are dense foams, but they can be pricey.

Expanded Polystyrene (EPS): according to the U.S. Department of Energy. It has an R-value of 4 and a thermal conductivity of about 0.25 W/(m・K). It’s very low cost, making it great for the construction industry. You can use it for roofs, partition walls, foundations, and more. It’s also perfect for insulated take-out containers and thermal boxes. Overall, it’s both economical and practical. It is economical and practical.

Extruded Polystyrene (XPS): XPS has an R-value of 5 and a thermal conductivity of about 0.2 W/(m・K). It is a strong, rigid foam, harder than EPS. This high-quality closed-cell foam is also waterproof and moisture-proof. Plus, it restricts airflow effectively.

It is suitable for use in areas with higher thermal conductivity requirements.

Polyiso (polyisocyanurate): This is a denser material and more expensive, although it has an R-value of 6. The thermal conductivity is about 0.167 W/(m・K). It typically uses an aluminum foil surface to reflect heat. It can also be applied to building exteriors due to its great reflective properties. It has low electrical conductivity. Also, it does not have hydrochlorofluorocarbons (HCFCs). These chemicals slowly lose their R-value over time.

Polyurethane (PU): Its R-value is usually in the range of 5 to 8. Thermal conductivity ranges from 0.125 to 0.2 W/(m·K). It fits many complex shapes easily. This material is great for refrigerated trucks, cold storage, RVs, and pipelines. There are many molding methods, making its applications very broad.

What is the skin of foam insulation boards?

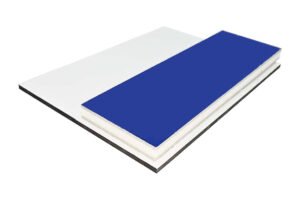

Foam insulation boards offer great thermal insulation. However, we have created different composite materials to expand their applications and versatility. It is possible to have different synthetic foam sandwich panels.

- Fiberglass foam insulated sandwich panels:

These foam insulated sandwich panels have thermal insulation foam inside. The outside is made of fiberglass sheet. They are strong and resist corrosion. Overall, they look great. It is durable and fireproof. You can use it in construction, industry, and more. It withstands harsh environments and keeps the internal temperature steady. This is why it’s used for refrigerated truck bodies. If you want to learn more about it, you can just review this page.

- Aluminum foam insulated sandwich panels:

Aluminum foam insulated sandwich panels are made with a core of insulating foam and an aluminum skin on the exterior, which has the advantage of being lightweight and is an excellent material that enhances decorative qualities, making it very popular for use on building exteriors and finishes, among other things.

- Carbon foam sandwich panels:

Carbon foam sandwich panels are made of carbon fiber skin on the outside and foam on the inside, and are mainly used in high-temperature environments and other special areas, such as cutting-edge technology.

Pros and cons of foam insulation

Insulation foam panels have a lot of benefits, so they are used in a variety of applications, favored by everyone, but at the same time, they also have certain shortcomings. With the development of materials science and applied research, I believe that one day, their shortcomings will also be gradually solved.

Pros.

- Noise reduction

Foam board has the function of reducing noise; after correct installation, it can absorb noise through the physical properties of the foam board. If used in the construction industry, its role is more obvious, but it should be noted that it is mainly used for thermal insulation rather than sound insulation. - Thermal insulation

Much has been said about the thermal insulation properties, which have a high R-value, so I won’t emphasize them here. - Moisture control

Rigid closed cell foam has good water and moisture resistance; it can be a very effective alternative to wood, which, because of moisture, can lead to rot and mold growth, making the wood unusable and harming the perimeter by letting water in. With foam, you can achieve good moisture resistance and other properties.

Cons.

- Price is higher.

Insulation foam will be slightly more expensive, but in comparison to its performance, it is still attractive, and we still recommend that you use rigid foam. - Weak fire resistance

After the extinction of the dinosaurs, large amounts of petroleum were formed underground, and plastic was refined from petroleum, and the plastic resin was made into rigid insulation foam. Because petroleum is combustible, foam is combustible. Foam should be used away from sources of ignition.

What is the foam insulation used for?

Building insulation foam is typically used in walls, roofs, attics, floors, partitions, and other areas of a building.

It provides good insulation and reduces the transfer of heat from the inside of the building to the outside, while making it difficult for cooler air to be conducted into the interior. Generally, in addition to insulating foam, other insulation materials such as insulating mineral wool will be used. Mineral wool boards have excellent fire performance, can combine heat insulation and fire prevention, and practicality.

Used in refrigerated truck bodies.

Insulated truck body panels made with fiberglass XPS foam are popularly used in refrigerated trucks, serving as the best choice of insulation material and, at the same time, play an excellent role in insulation, can replace traditional mineral wool and wood, etc. XPS foam can be done without absorbing water performance, making it suitable for use in refrigerated trucks.

Author introduction

Hello, customers

My name is Jack Yu and I am the Business Manager of Composite Box. I have been in the business of sandwich panels, refrigerated trucks and RVs for more than 10 years. Please feel free to contact us. I am happy to provide you with the best service and products.

Email: info@composite-box.com | Tel: 86+17280837525