Fiberglass Box Truck Body solution

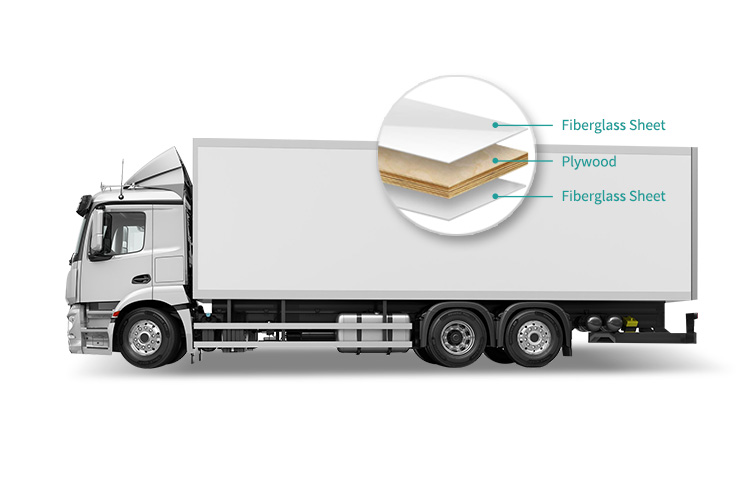

When you are choosing a fiberglass truck body, you must be concerned about the fiberglass sandwich panels used in its construction and want it to have high performance and durability with a long service life.

Undoubtedly, what you are looking for is us, composite box’s fiberglass truck body is designed for modular assembly, CKL and CKD deliveries, and complete fiberglass truck kits are available. whether you need a box truck body, reefer truck, side curtains, small trailer, ambulance, just use our fiberglass customized solutions, our experts try to meet all your needs as much as possible.

Features

Fiberglass is one of the best choices for truck bodies.

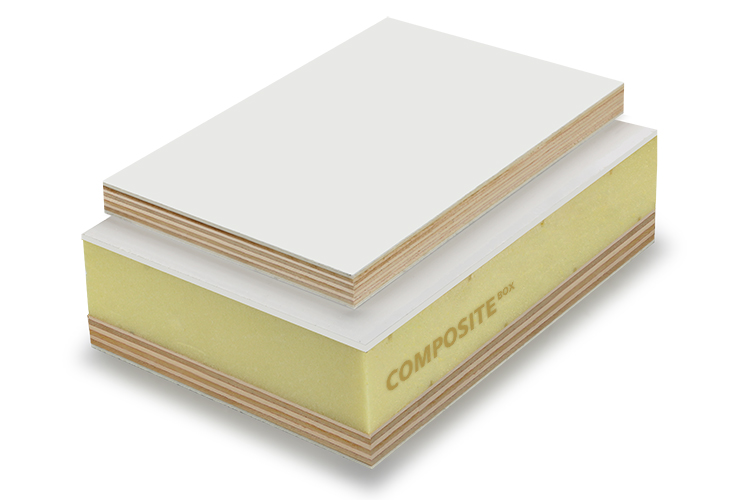

The fiberglass plywood panels for truck utilize lightweight foam cores, achieving remarkable weight reduction while thanks to the foam lightweight. This is due to the light weight of the foam, which can reduce the weight under the guarantee of strength, compared with the metal truck body, its weight is more than 40% lighter, which is of course not a joke.

Fiberglass surfaces can resist corrosion, and are waterproof and moisture-proof, in acidic and alkaline substances, can still maintain stability, will not be destroyed. So that’s why fiberglass truck bodies have gotten so hot over the years.

In addition to the above, fiberglass trucks have a lifespan of over 30 years and are easy to maintain and affordable. Compared to traditional steel, aluminium and wood, fiberglass completely crushes them in terms of performance, and benefits.

Get Free Quote of Fiberglass Box Truck Body solution

product Catalog

contact us

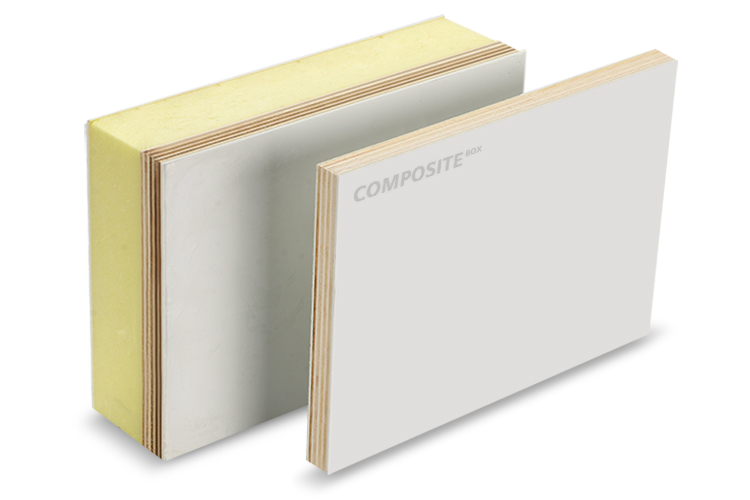

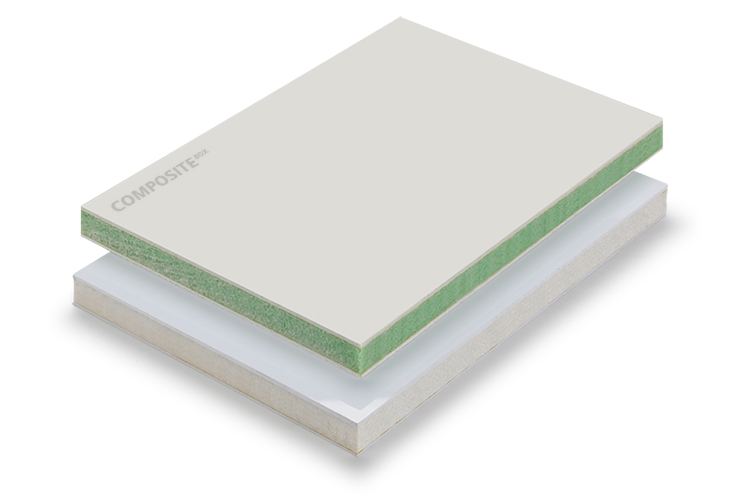

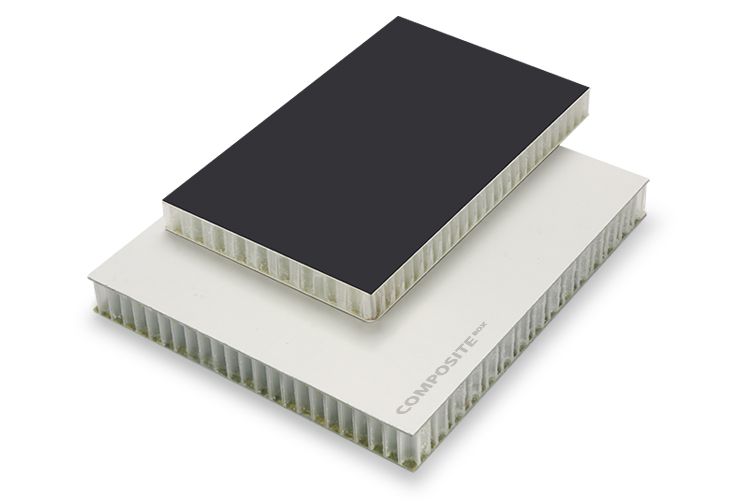

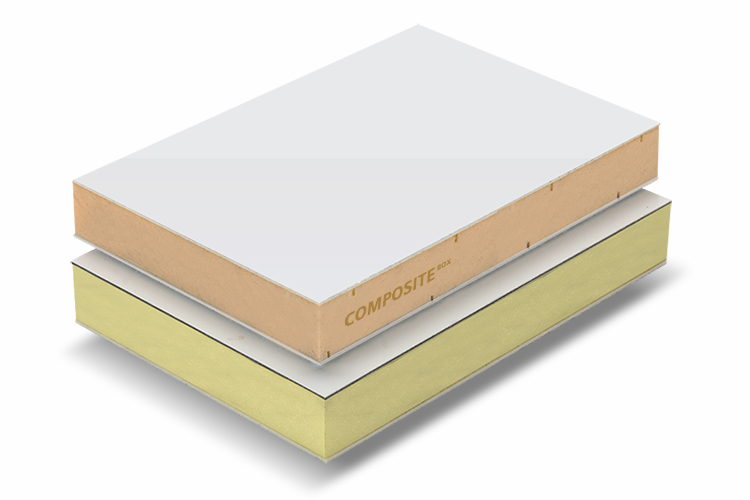

Fiberglass truck body material selection

Use FRP sheet, core can choose PET, PVC, PP and plywood.

Why choose us?

Composite Box has been developing and designing fiberglass dry van bodies for over 20 years, We have thousands of van design examples and have a production factory that strictly adheres to relevant international standards to ensure long-lasting quality.

Our fiberglass vans have versatile accessories and kits

Interior trim: the same variety of flooring, T-vent slots, diamond non-slip flooring, honeycomb non-slip flooring, e-track (recessed locking track), meat hooks, kick panels, LED spotlight inside the car, Bumpers, outline lights, reflective tape, etc.

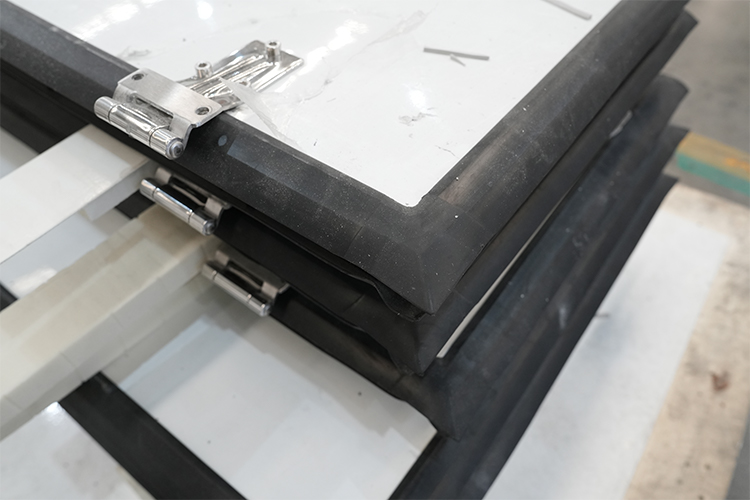

Cooling units, different types of side and rear doors, built-in locks, hinges, and side rails are optional packages available.

Common Parameters

| Dimension (M) | Load (Tons) | Volume (m³) | Notes |

|---|---|---|---|

| 4.2 × 1.9 × 1.9 | 2 | 15 | Small size, suitable for light loads. |

| 4.2 × 2.1 × 2.1 | 4 | 15 | Slightly wider and taller than 4.2×1.9×1.9. |

| 5.2 × 2.1 × 2.1 | 5 | 25 | Increased length for higher capacity. |

| 6.8 × 2.4 × 2.7 | 10 | 40 | Medium size, ideal for general freight. |

| 7.6 × 2.4 × 2.7 | 12 | 45 | Longer body for heavier loads. |

| 8.7 × 2.4 × 2.7 | 15 | 55 | Large size, suitable for bulk cargo. |

| 9.6 × 2.4 × 2.7 (Rear 4 wheels) | 16 | 60 | Extended length for high-volume loads. |

| 9.6 × 2.4 × 2.7 (Rear 8 wheels) | 18 | 60 | Higher load capacity with additional wheels. |

| 12 × 2.4 × 2.5 | 30 | 70 | Extra-long body for heavy-duty freight. |

| 13 × 2.4 × 2.5 | 30 | 75 | Longer body with increased volume. |

| 15 × 3.0 × 2.7 | 30 | 100 | Largest size for heavy-duty and bulk cargo. |

| 17 × 3.0 × 2.7 | 30 | 120 | Extra-large size for maximum capacity. |

Application

FRP truck bodies can be used to transport products such as fruits, vegetables, meat, medicines, cosmetics, food packaging, etc. and are widely used to transport everything.

Related Product

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.