Best Carbon Fiber PP Honeycomb Panel Manufacturer

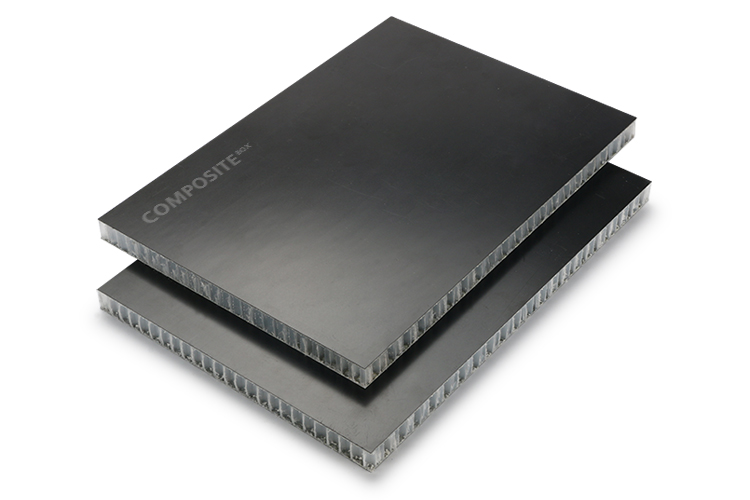

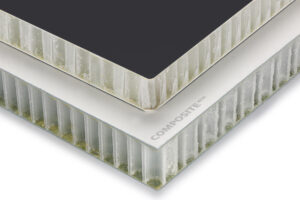

Carbon fiber PP (polypropylene) honeycomb panels have a PP honeycomb core. They have a carbon fiber skin for better performance.

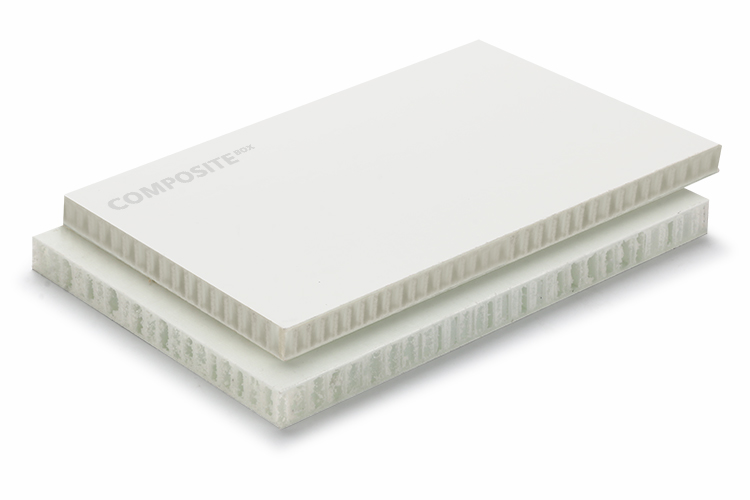

Composite Box offers 10-20mm carbon fiber honeycomb panels. They perform better than metal and aluminum honeycomb panels. They are cheaper and lighter, too. Available in half and full carbon and in a variety of carbon fiber textures. With a better strength-to-weight ratio, Has a better strength-to-weight ratio, 35% to 70% lighter than aluminum, can replace steel and aluminum, is one of the more popular composite honeycomb panels on the market. We are the best carbon fiber honeycomb panel manufacturer, and we offer 100% customized service!

Features

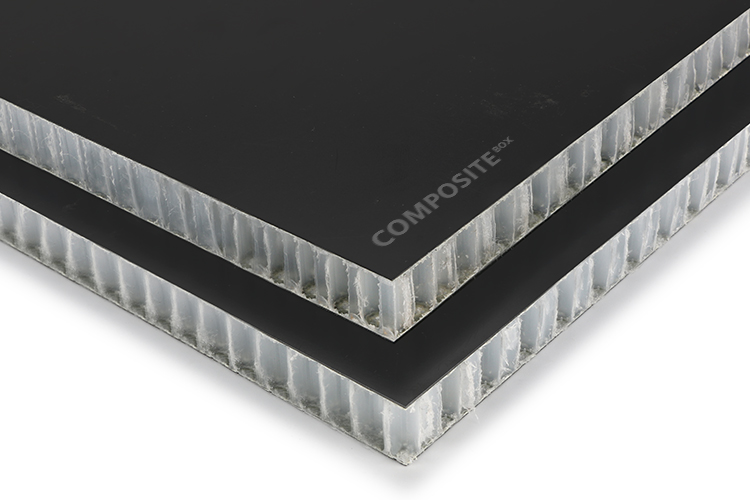

Carbon fiber PP (polypropylene) honeycomb panels can withstand great pressure. They are tough and can endure high loads without deforming in high-strength uses. The core uses high-quality PP honeycomb that presents a honeycomb, lightweight, low-cost structure capable of dispersing pressure, with features that can be widely used in aircraft fuselages, yachts, buildings, sporting goods, and more.

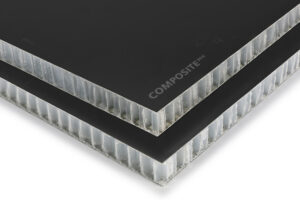

Manufacturing Process:Composite Box carbon fiber honeycomb panels are manufactured using an advanced high pressure unibody molding process where the carbon fiber skin and polypropylene honeycomb core are tightly bonded. In the future, there will not be delamination and cracking, etc., and has a very high performance.

The following are the characteristics:

- Low coefficient of thermal expansion

- Stable in extreme environments, such as high and low temperatures.

- High strength; not easy to deform and bend.

- Good toughness; not easy to break.

- Superior to solid laminates and metal honeycomb panels.

Get Free Quote of Carbon Fiber PP Honeycomb Panel

product Catalog

contact us

Products customized

We are the best carbon fiber manufacturer. We provide custom solutions for carbon fiber facing, similar to our aluminium honeycomb panel options, The tows are 3K, 12K, and 18K. You can choose the carbon fiber texture and structure.Our products undergo strict quality testing and stand the test, welcome to contact our experts, you can get more technical support and information services!

Carbon fiber structure

Surface Finishes:

Teflon-frosted and fine-frosted.

Teflon makes the surface more resistant to corrosion, chemicals, heat, and adhesion.

Fine Brushed Finish: The surface is finer and smoother.

Carbon fiber texture:

Carbon fiber facing is of two types: unidirectional and bidirectional. Bidirectional carbon fiber has three weaves: plain, twill, and satin.

In addition, we provide CNC cutting, finishing, and other services.

In addition, we offer CNC cutting, finish machining Surface gel-coating, and pre-assembled wiring are available to meet your needs.

Full Carbon:

T300 and T700 carbon fiber differ in strength, toughness, and rigidity. T300 has a tensile strength of 3500 MPa, while T700’s is 4900MPa. If you need higher strength and rigidity, the T700 is the best choice. But, the T300 costs less.

Semi-Carbon:

Contains a certain percentage of glass fibers and consists of two options:

Single carbon fiber and double glass fiber

Dual carbon fiber and single glass fiber

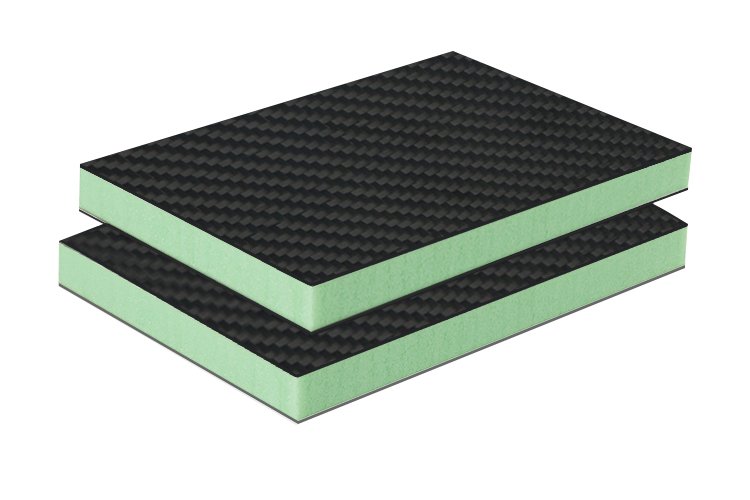

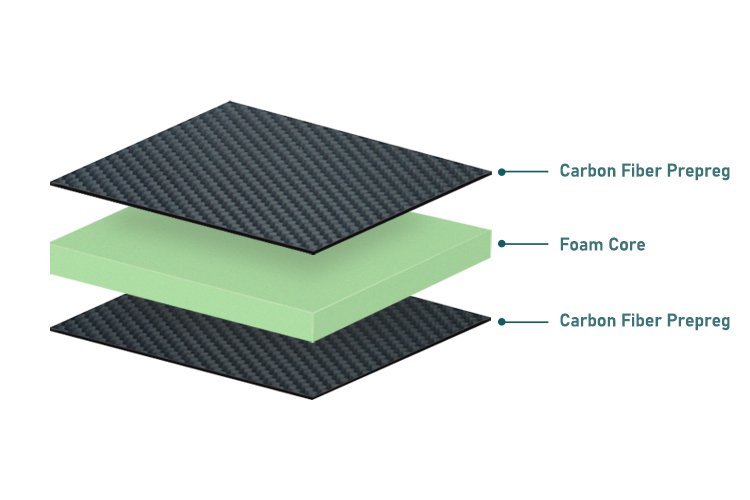

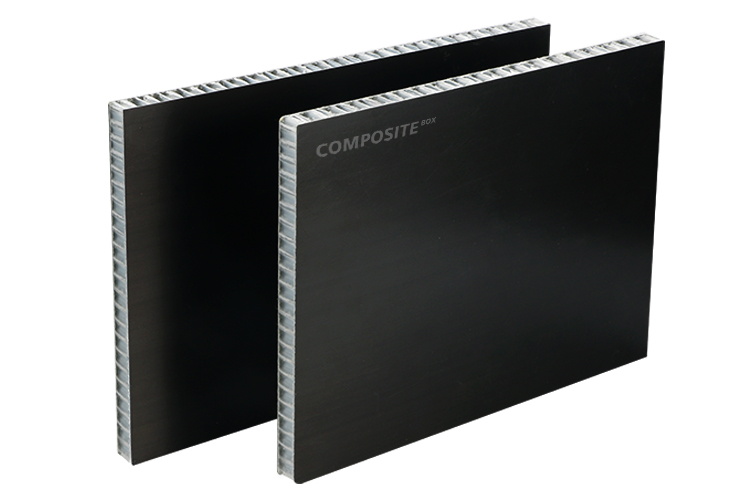

Structure of Carbon fiber PP honeycomb panels

Carbon fiber facings:

Carbon fiber skin is ultra-strong, lightweight, and corrosion-resistant. It has a beautiful appearance. So, it is widely used in high-end composites.

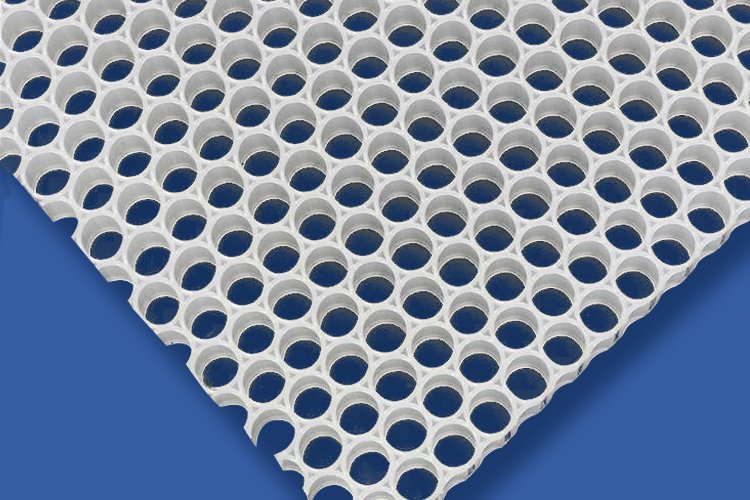

PP honeycomb panel:

PP honeycomb core has a circular structure. It is lightweight and compression-resistant. It also absorbs energy, insulates sound, and dampens vibrations. These properties make it a popular core material.

Application of Carbon fiber PP honeycomb panels:

Carbon fiber PP honeycomb panels can be used in many applications that require high performance materials because of their hollow core, energy absorption, high strength, and low coefficient of thermal expansion.

- Tennis Rackets, Pitbull Rackets

- Architectural wall panels

- Wing and fuselage materials

- Ship’s plywood, trim, etc.

- Truck bodies, etc.

Product Parameters

| Parameter | Details |

|---|---|

| Carbon Fiber | T300, T700, T800, T1000 Carbon Fiber Surface |

| Maximum Size | 11.8 m (Length) × 3.3 m (Width) |

| Thickness Range | 6 mm – 50 mm |

| Core Material Option | PP Honeycomb |

| Surface Treatment | Glue-coated Carbon Fiber |

| Weight | 40% – 70% Lighter than Aluminum |

| Water Absorption Rate | < 1.5% |

| Surface Finish | Glossy / Matte |

| Finish | Satin |

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.