Fiberglass Reinforced Plywood Sandwich Panels

Fiberglass reinforced plywood panels are a high-strength, impact-resistant material that consists of 2 pieces of FRP sheets and plywood and is formed into FRP plywood panels. They can withstand great pressure and have the advantages of both FRP and plywood and are widely used in various applications.We work as a professional supplier for you.

We support customized production, OEM/ODM, and finished products such as trailers, carriages, and motor homes.

Features

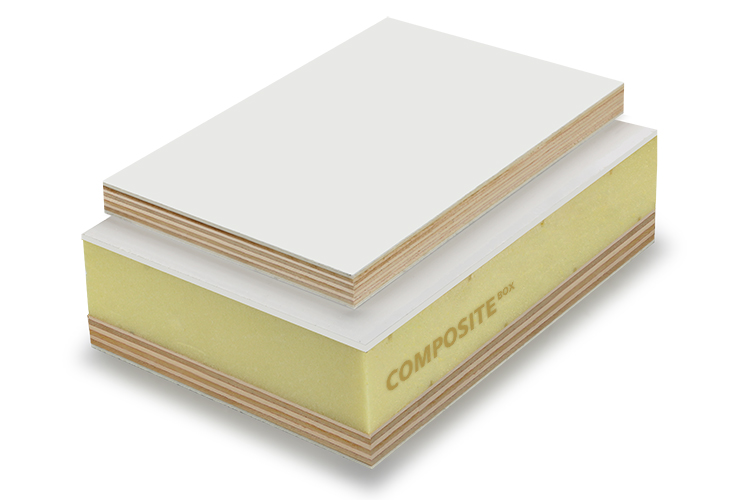

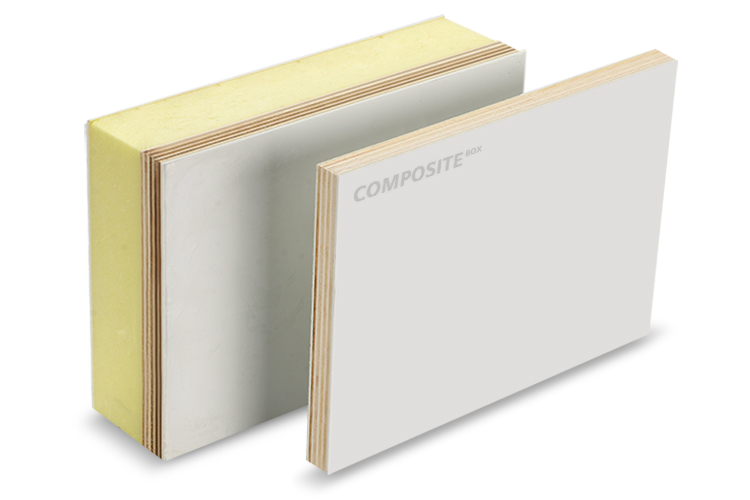

Fiberglass reinforced plywood panel structure: 2 layers of fiberglass sheets as exterior, core of plywood, formed by laminating 7 to 13 layers of thin wood.

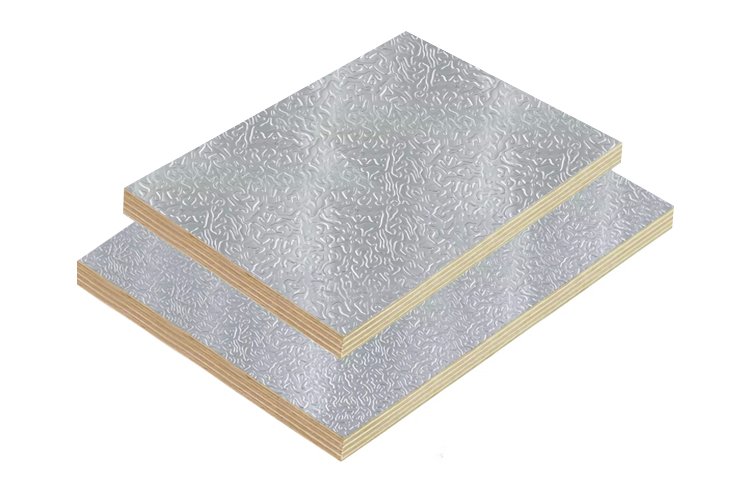

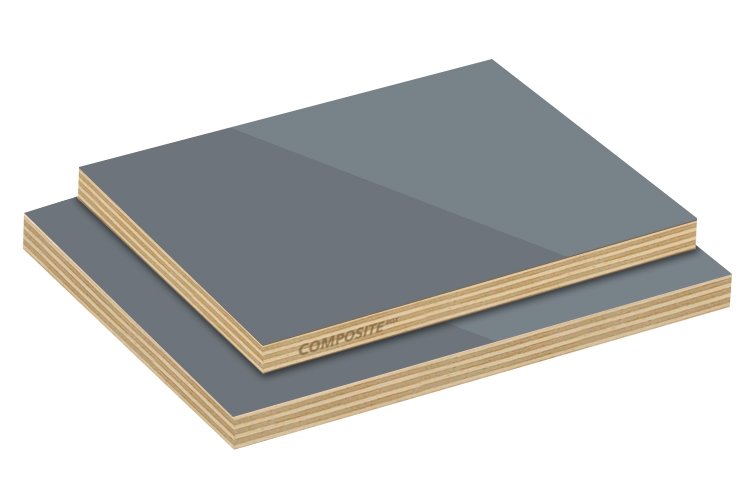

Composite-box has 20+ years experience in producing premium fiberglass plywood panels for truck applications. Although plywood panels are a high-strength material, they are not waterproof, are prone to rot, and have many disadvantages. Nowadays, with FRP skin, they are able to be waterproof, scratch-resistant, rot-resistant, and UV-resistant, among other benefits. Options like stainless steel faced plywood also enhance durability for specific applications. These features make our fiberglass plywood panels the ideal choice for truck applications.

Get Free Quote of Fiberglass Reinforced Plywood Sandwich Panels

customization

We support product customisation and can produce different thicknesses on request, from 9mm to 22mm, lengths up to 12m and widths up to 3.2m. Customized FRP patterns and colours are available, as well as different skin finishes, and non-woven fabrics can be added to enhance adhesion. Sourcing fiberglass reinforced plywood, composite box is the best choice.

Product Advantages

Application

Structure of fiberglass plywood

plywood

plywood is multiple layers of different thin wood slices laminated with adhesives to achieve high strength properties and is highly resistant to compression, maximizing the use of wood.

FRP Fiberglass sheet

PET (polyethylene terephthalate) is chemically stable, is recognized worldwide as an environmentally friendly recyclable material, consists of a closed cell structure, is waterproof and moisture resistant, and is the ideal material for many applications.

Application of fiberglass reinforced polywood panel

FRP sandwich panels can be used mainly in scenarios that need high strength.

Product Parameters

| Attribute | Specification/Value |

|---|---|

| Skin Thickness | 1.5 mm |

| Core Thickness | 11 mm |

| Areal Density | 1 Kg/m² |

| Flexural Strength | 36.966 MPa (Max Load: 2770.659N, Sample Size: 300x100x14 mm) |

| Compressive Strength | 13.053 MPa (Max Load: 2770.659N, Sample Size: 60x60x14 mm) |

| Skin Material | FRP (Fiberglass Reinforced Plastic) or CFRT (Continuous Fiber Reinforced Thermoplastic) |

| Core Material | Plywood (Poplar, Pine, Eucalyptus, Oak, etc.) |

| Surface Treatment | Gelcoat FRP (Thickness: 0.7–5.0 mm) |

| Composite Method | Eco-friendly adhesive |

| Thickness Range | 5–50 mm |

| Length Range | ≤12000 mm |

| Width Range | ≤3200 mm |

Comparison of FRP skinned plywood and pure plywood performance

| Item | Strength | Waterproof Performance | Fire Resistance | Surface Smoothness | Expected Lifespan | Moisture Resistance | Thermal Insulation |

|---|---|---|---|---|---|---|---|

| FRP Skin Plywood | Excellent | Excellent | Average | Smooth | Long | Good | Excellent |

| Pure Plywood | Average | Poor | Poor | Rough | Short | Poor | Average |

Custom Processing

Embedded Reinforcement Structures

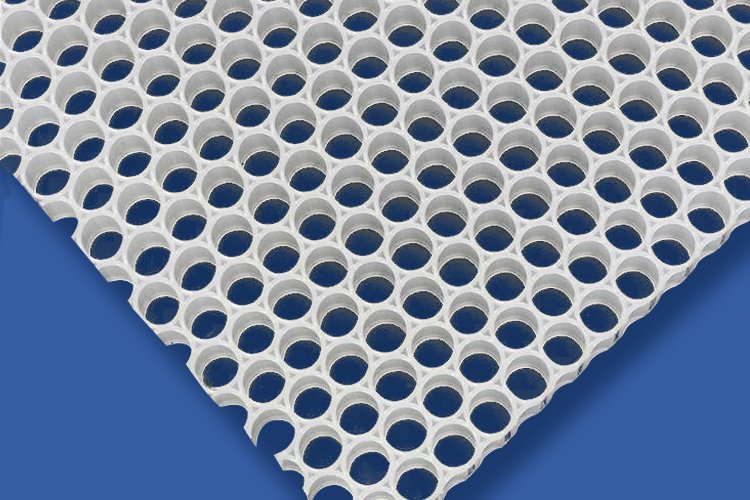

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

FAQ

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.