Best RV fiberglass panels manufacturer in china

RV motorhomes are manufactured from fiberglass composite panels, thermoset polyester resin and short cut glass fibre tow. The core uses foam, plywood or PP honeycomb. is a lightweight sheet. Meet the needs of DIY customisation. Various finishes. Can be used for RV exterior sidewalls, RV fiberglass siding panel, coiable exterior, doors, roof panels, interior panels and floors, as well as in fiberglass enclosed trailers. Can also be used for repair panels. It has thermal and acoustic insulation effect. Low cost, high performance and easy maintenance. Available in customised sizes, colours and thicknesses. Favoured by a wide range of customers.

Provide 3D design for RV, with better performance than traditional aluminium composite panels. Provide service for RV trailer, small camper, truck camper, C-type caravan, teardrop caravan and caravan.

We are pleased to offer you the following products:

- Exterior wall panel

- fiberglass side panels

- RV laminate sheet

- Roofs

- Floors

- Wall panels

- Interior walls and partitions

Related Product:

RV Wall Panels

Provide lightweight RV wall panels, provide FRP composite panels, embedded structural design, CNC machining, can reduce the weight of RV, provide up to 11.8 meters, thickness 10~130mm.

RV Roof Panels

RV roof is made of FRP composite material with waterproof performance and strength, embedded design can increase the load capacity. RV roof panels can be designed for installation of air conditioning, windows and wiring.

RV Fiberglass Siding

RV fiberglass siding is made of fiberglass material and is the best RV covering material for scratch resistance, impact resistance, and extended service life.

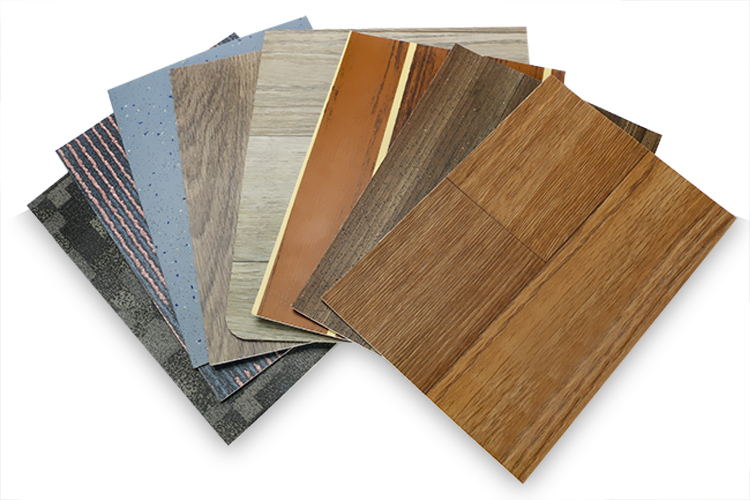

RV Camper Vinyl Floor

Vinyl flooring for RV campers is the smart choice. Multiple finishes are available, faux wood grain, faux tile. It offers versatility, durability and water resistance.

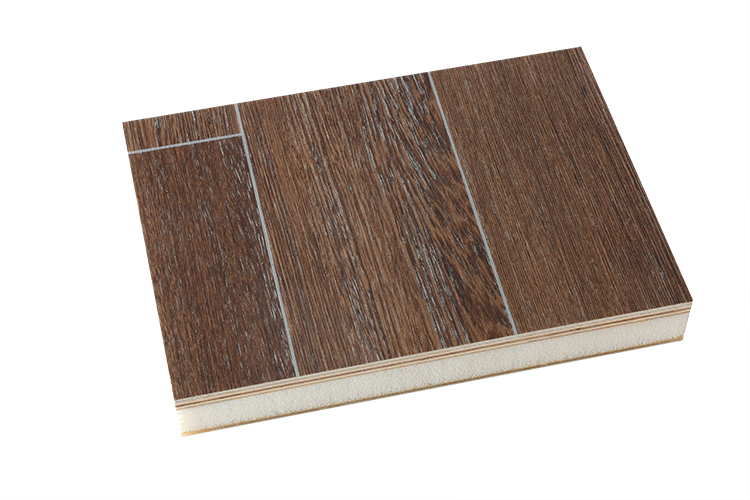

RV Sandwich Foam Flooring

RV sandwich foam flooring is lightweight and durable. There are a total of 3 layers of construction that make up the core using plywood or foam and the flooring using wood flooring, vinyl, rubber and other flooring.

Description:

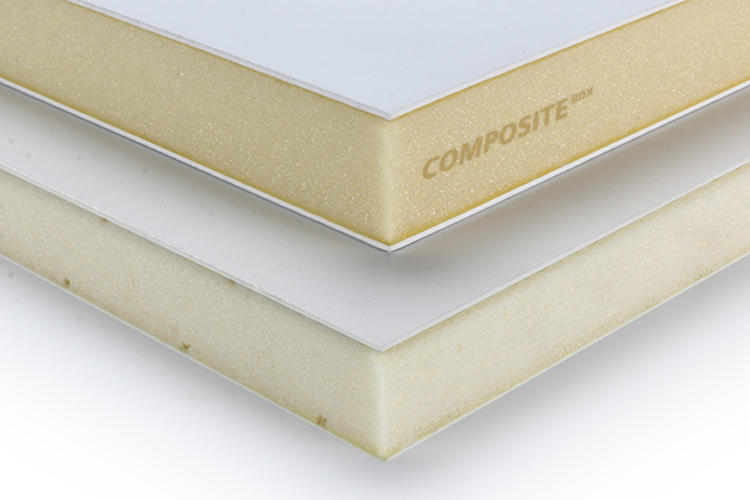

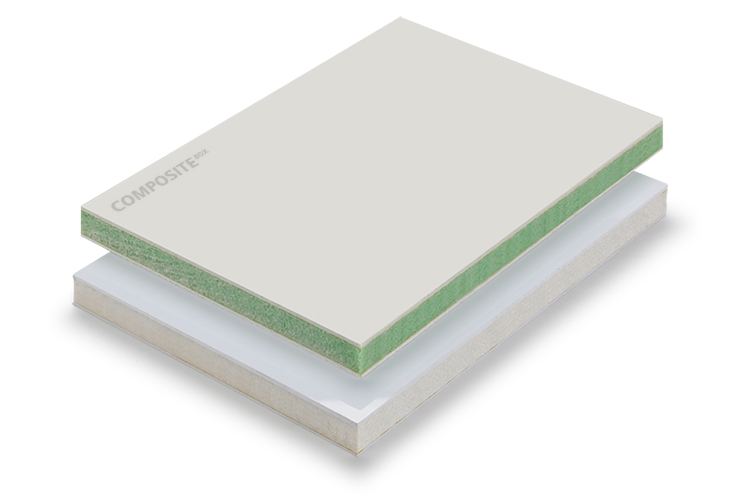

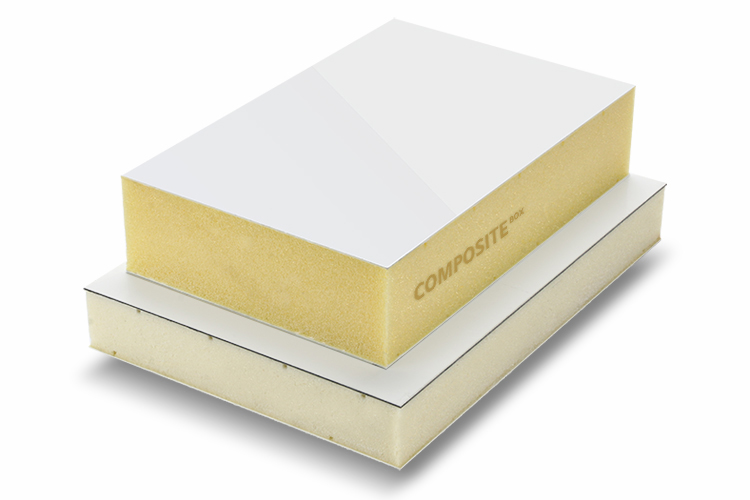

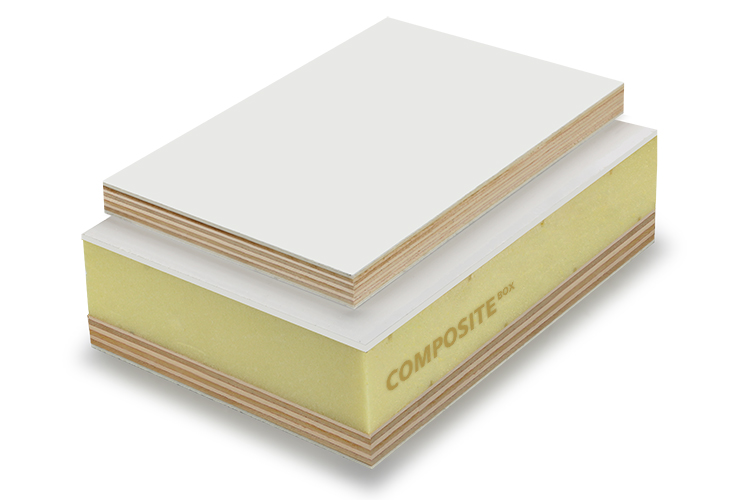

FRP foam core panel is the best choice for RV, whether it is used for the structure or interior of the RV, or even for beds, cabinets and partitions.

- Insulation: It can maintain the internal temperature even in cold areas.

- Lightweight: It is light in weight and can replace traditional aluminum foam sandwich panels

- High strength: FRP has high strength and good toughness

- Anti-scratch: FRP surface is strong and very wear-resistant

- Easy to maintain: It is easy to clean and maintain, and the maintenance cost is lower than that of aluminum alloy panels

- Beautiful: Using gel coating and laminating film, the surface is beautiful, and a variety of finishes are available.

- Waterproof and moisture-proof: The surface is smooth and the performance will not decrease in harsh conditions

Customization:

- Size: can be customized in different sizes, the widest 3.2 meters, the longest 11.8 meters

- Skin customization: can be customized for FRP with various colors and layers

- Internal structure: For more solidity, the interior can be reinforced with aluminum tubes, FRP tubes, or choose plywood foam core panels as a lightweight, high-strength core option.

- CNC processing: CNC can be used for cutting, milling and other processing.

- Corner aluminum profiles: Use aluminum profiles, etc.

- Surface treatment: can be customized with high-gloss, matte, imitation wood grain, etc.

parameter

fiberglass composites vs traditional materials

| Feature | Fiberglass Composite (FRP) | Aluminum | Wood | Steel |

| Weight | Lightweight | Moderate | Light | Heavy |

| Corrosion Resistance | Excellent (UV, moisture, chemicals) | Moderate | Poor | Poor |

| Thermal Insulation | High (low thermal conductivity) | Low | Moderate | Low |

| Durability | High (impact-resistant) | Moderate | Low | High |

| Maintenance | Low (easy to clean) | Moderate | High | High |

FAQ

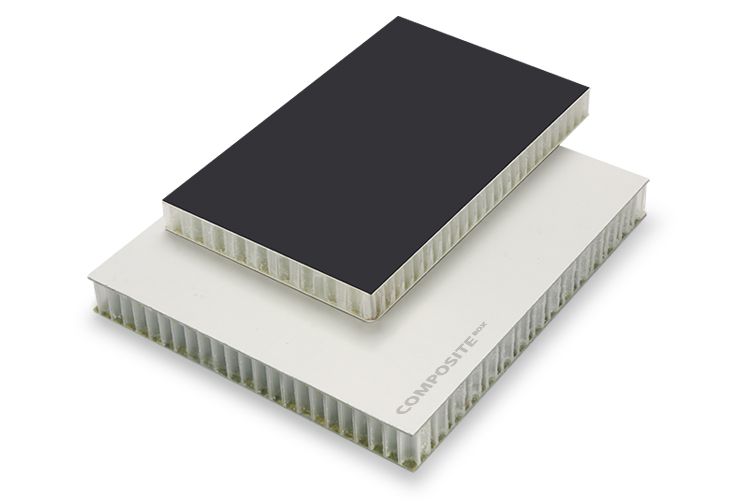

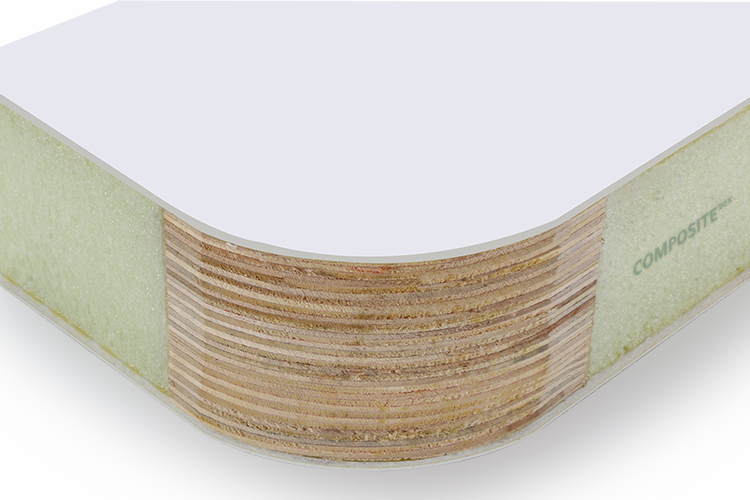

Structure of RV fiberglass sandwich panels

fiberglass sheet:

Use fiberglass sheet, made of high strength fiberglass and thermosetting resin composite, with excellent abrasion resistance, corrosion resistance and compression resistance. It is the best choice for RV, truck camping, hard shell rooftop tent, which can be suitable for many harsh environments.

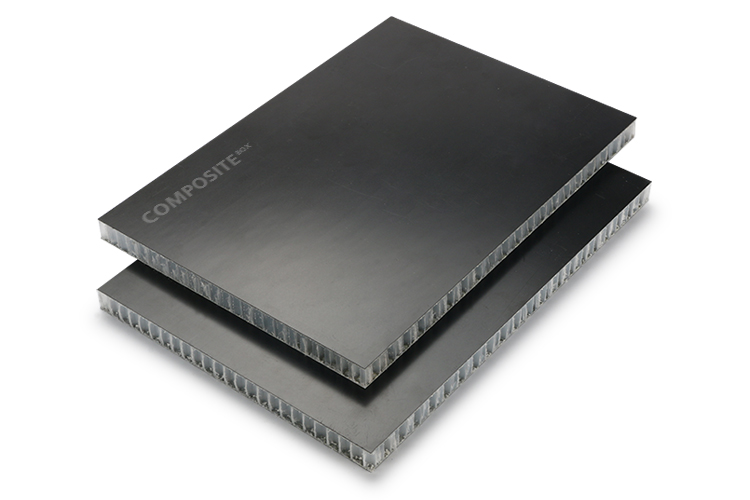

sandwich core:

You can choose XPS foam board, PET foam board, PVC foam board, PU foam board, or use PP honeycomb board or plywood sandwich, Discover our carbon fiber honeycomb panels for premium strength and lightweight performance. We support structural design and meet your requirements.

Related RV Sandwich Panels

Composite Box

Application of RV fiberglass panels :

Our RV fiberglass panels are very versatile:

Technical Parameters

| Project Specification/Description | Details |

|---|---|

| Skin Material | Gel – coated FRP board, CFRT (Continuous Fiber Reinforced Thermoplastic) board |

| Core Material | PET foam, XPS foam, PU foam, MPP foam, plywood, EPP foam, PP honeycomb board, etc. |

| Width | ≤ 3.1 meters |

| Length | ≤ 11.8 meters |

| Skin Thickness | 0.4 – 5mm |

| Core Thickness | 10 – 80mm |

| Skin Color | Selectable from RAL color card series |

| Surface Treatment | Anti – UV gel coating, anti – UV laminating film, embossing treatment (providing texture effect) |

| Processing Method | CNC processing services (cutting, milling, etc. for fine processing), embedded structure processing (can embed aluminum tubes, FRP tubes, etc.) |

| Compressive Strength | Depending on the core material, the compressive strength range is: 50 – 200 kPa |

| Temperature Resistance Range | – 20°C to + 90°C |

| Weight | Customized according to size and thickness, weight range: 4 – 10 kg/m² |

| Sound Insulation Performance | Excellent sound insulation effect |

| Service Life | Long – term durability, anti – UV aging performance can reach more than 10 years |

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.