Lightweight Reinforced Thermoplastic (LWRT)

Lightweight Reinforced Thermoplastic Material, also known as LWRT, is a glass fiber composite material used in the automotive industry. It is made from glass fiber and polypropylene in a 50:50 mass ratio. It is produced through a process of wrapping, combing, web formation, needle punching, and hot pressing. It has thermoplastic properties and is a GMT material. It offers the advantage of low cost while also providing the benefits of high performance.

Product Description

Lightweight reinforced thermoplastic materials offer numerous advantages that are highly compelling.

- Lightweight Performance: Utilizes lightweight materials, resulting in extremely low density.

- Bending Resistance: Resistant to bending, with bending strength ranging from 50 to 150 MPa.

- Impact Resistance: LWRT exhibits excellent impact resistance, typically ranging from 20 to 50 kJ/m².

- Environmental Friendliness: It has significant environmental advantages, with no harmful substance emissions.

- Flame Retardancy: LWRT has excellent flame retardancy, effectively preventing fire spread.

- Durability: It has a long service life, is resistant to aging, and reduces the need for replacements.

performance table

| Parameter | Typical Value / Range |

|---|---|

| Glass Fiber Content | 20%-50% |

| Matrix Material | Polypropylene (PP) |

| Density | 0.9-1.2 g/cm³ |

| Impact Strength | 20-50 kJ/m² |

| Hot Pressing Temperature | 180-220°C |

| Hot Pressing Pressure | 1-5 MPa |

| Molding Thickness | 1-10 mm |

| Recyclability | 100% Recyclable |

parameter table

| Basis Weight (g/m²) | Thickness (mm) | Lamination Depth (mm) | Tensile Strength MD (N) | Tensile Strength TD (N) |

|---|---|---|---|---|

| 900 | 1.8 | 5-8 | 10 | 7 |

| 1000 | 2.0 | 6-9 | 15 | 12 |

| 1150 | 2.3 | 7-10 | 20 | 16 |

| 1250 | 2.7 | 8-11 | 25 | 20 |

| 1350 | 3.0 | 9-12 | 30 | 24 |

| 1600 | 3.5 | 10-14 | 45 | 35 |

| 1900 | 4.0 | 12-16 | 60 | 45 |

| 2200 | 4.5 | 14-18 | 80 | 60 |

| 2600 | 5.2 | 15-20 | 110 | 85 |

Get Free Quote of LWRT

Application

LWRT materials are suitable for manufacturing underbody shielding protection devices, load-bearing plates, roof linings, door decorations, luggage racks, roof molding, engine hoods, trunk covers, etc.

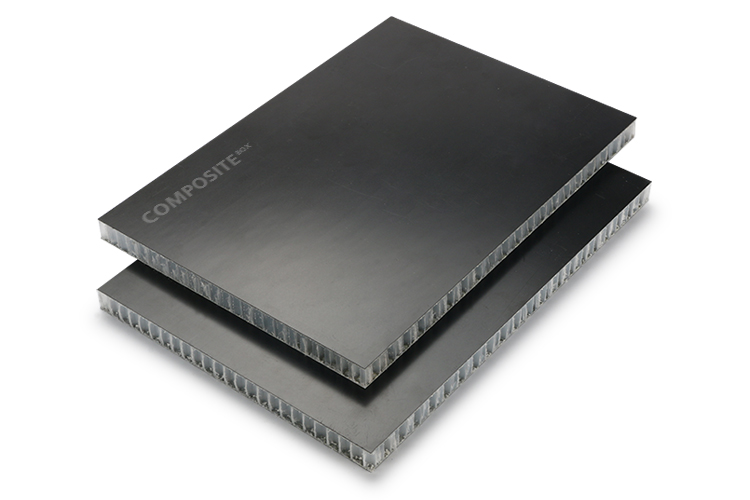

Basis Weight: 850 – 1200 g/m²

- High strength, light weight

- Good sound insulation and heat insulation

- Excellent moldability and mechanical properties

- Low density, good surface quality, no formaldehyde, environmentally friendly, suitable for automotive interior parts

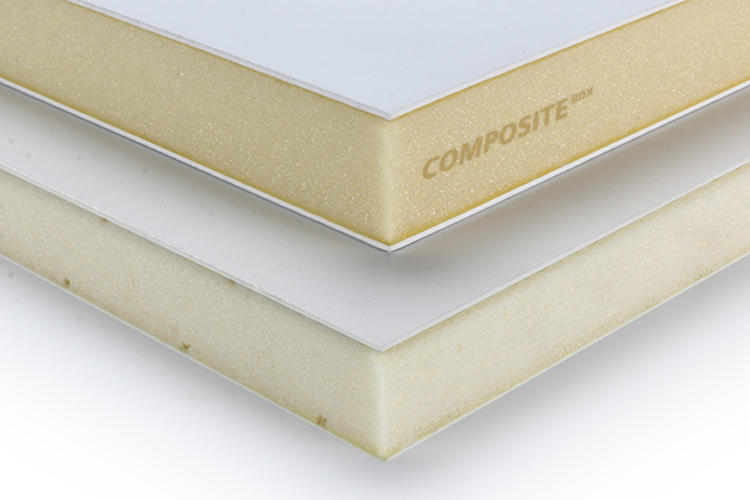

Basis Weight: 1000 – 2500 g/m²

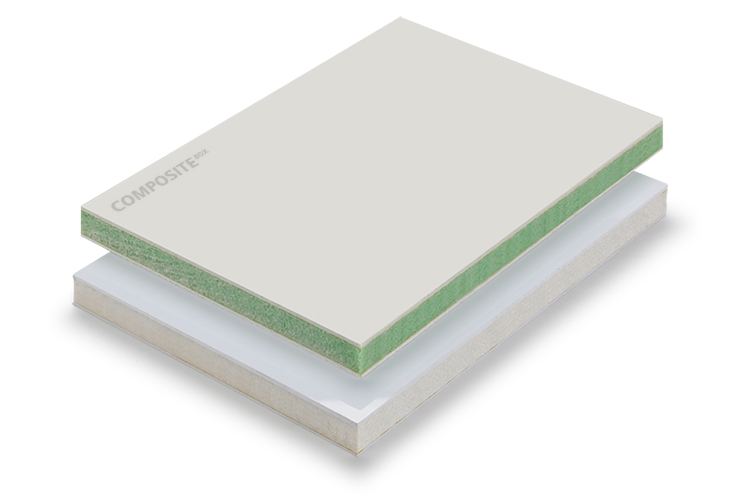

- Three layers: surface layer + intermediate layer + bottom layer

- Surface Layer: 200-1000 g/m²

- Intermediate Layer: 200-2000 g/m²

- Good sound insulation, low density

- High strength, good toughness

- Good moldability, easy to process

- Green environmental protection, no formaldehyde, suitable for automotive interior parts, environmentally friendly

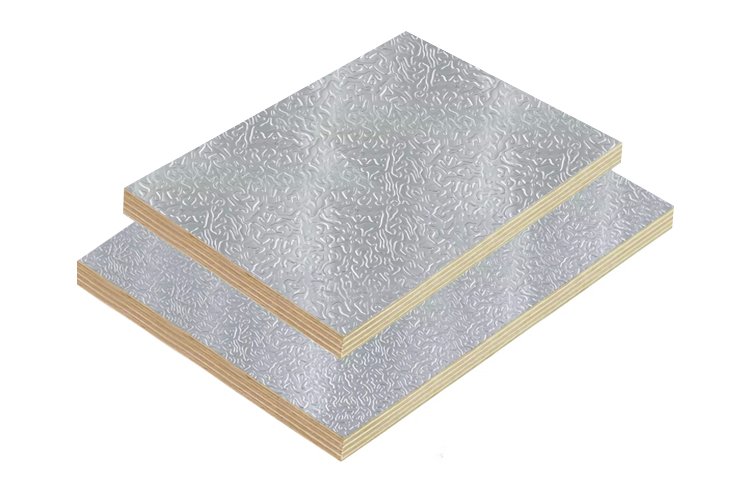

Basis Weight: 800 + 640 (Estimated: 800 g/m²

)

- High strength, good toughness

- Excellent sound insulation and heat insulation

- High moldability, suitable for complex parts

- Environmentally friendly, no formaldehyde

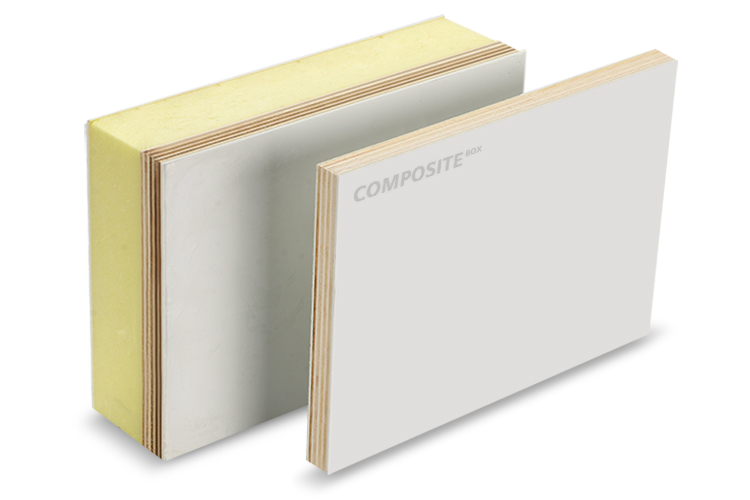

Basis Weight: 1600 – 2200 g/m²

- High strength, good toughness

- Excellent sound insulation and heat insulation

- High moldability, suitable for complex parts

- Green environmental protection, no formaldehyde, no odor, suitable for automotive interior parts

vedio

related Product

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.