Composite Camper Body Manufacturer In China

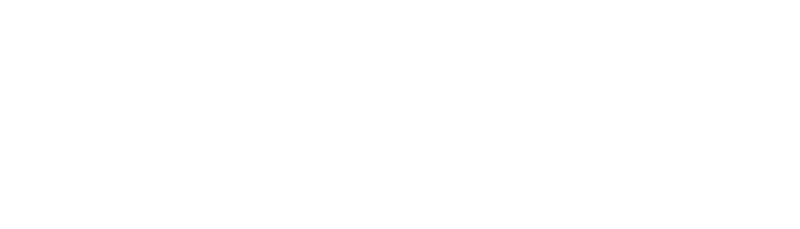

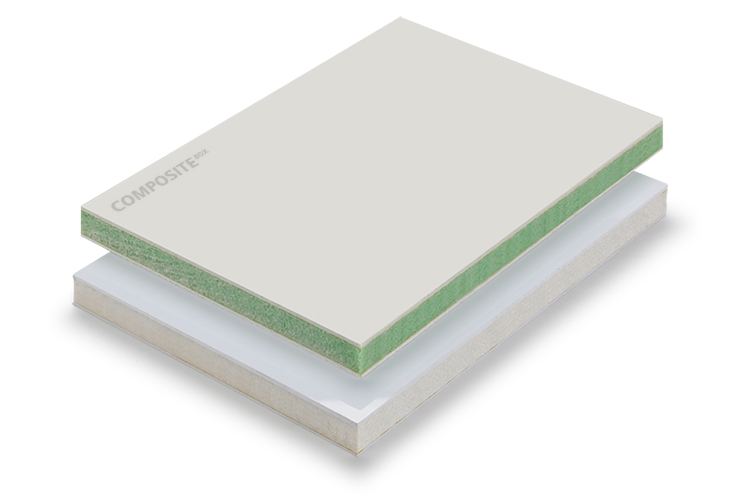

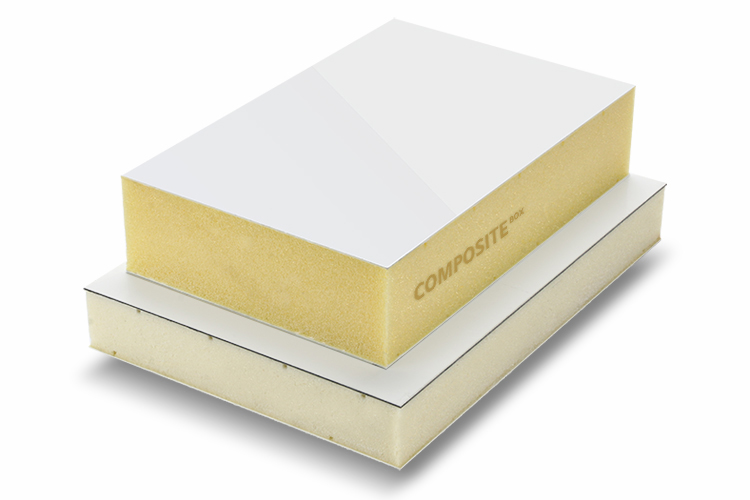

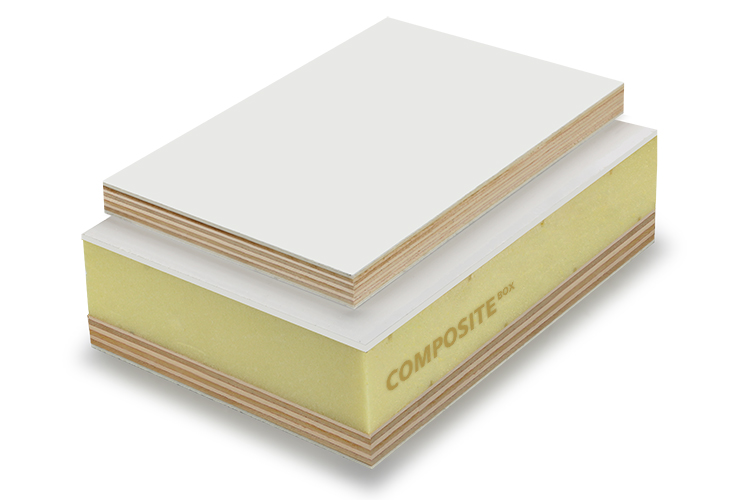

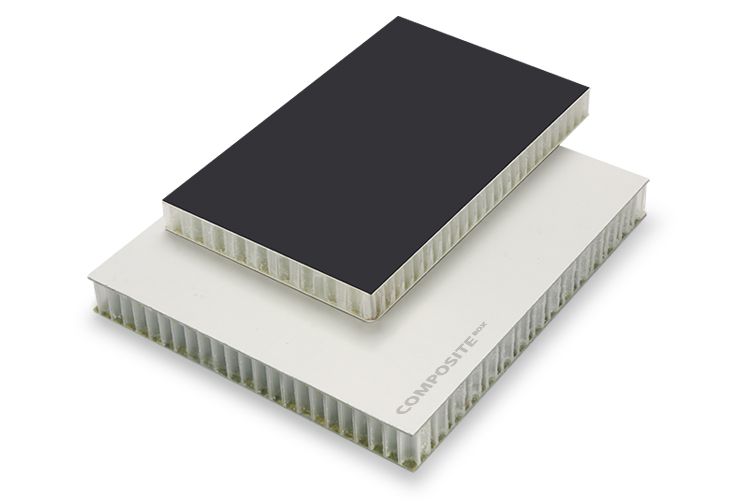

Composite box is one of the top professional campervan, RV manufacturers, we have our own factory. We produce fiberglass sandwich panels, plywood, PP honeycomb panels for manufacturing body boxes. Support OEM production, compatible with all kinds of cars, provide the most professional solution for camping box.

Production models: composite RV box, hard shell roof tent, teardrop trailer, RV trailer, truck camping body, class C motorhome, off-road trailer and so on.

- Diverse Product Range: Offer a wide variety of camper – related products.

- Flexible Customization: Provide 100% customization to meet various needs.

- Reliable Quality: Strictly control production processes for product quality.

Related Product:

Class C RV

Description:

The class C RV is lightweight with fiberglass sandwich panels. Similar to a box van, it can be equipped with kitchen, bathroom and storage space.

Truck Camper

Description:

Truck camping kits and enclosures using fiberglass, slide-in for pickup or cargo trucks. Lightweight, length 1.5~2 meters. Support OEM.

Teardrop Trailer

Description:

Length up to 14 feet, shaped like a teardrop, composite material, long life, can be equipped with bed, kitchen, front storage space.

Camper Small RV Trailer

Description:

The Camping Small RV Trailer accommodates 2 to 5 people, is lightweight, versatile, and comes fully kitted.

Hard Shell Rooftop Tent

Description:

Best hard shell rooftop tent with aluminum brackets. Can be used for pickup trucks and SUVs etc. Can be used for 2 to 4 people, able to install air conditioning, roof windows.

Other Product

Contact Us

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.