fiberglass enclosed trailer

Fiberglass enclosed trailers are designed and manufactured with fiberglass composite materials, changing the market for traditional aluminum and wood trailers.Fiberglass trailers are wood free and are unbeatable in terms of performance, longevity, and weight. Our fiberglass trailers can be used for a wide range of purposes, whether it is used to transport furniture, goods, parts, packaged goods, or used to convert into a motorcycle trailer, moving trailer. All are the best choice.

- Modular design

- Good impact resistance.

- Good insulation

- Long service life

- Good durability

Features

We offer fiberglass enclosed trailer and also fiberglass trailer panels including side panels, roof panels and fiberglass floor. We offer modular design, CKD and SKD assembly delivery. With material options and customized sizes, we are the leading trailer supplier.

Get Free Quote of fiberglass enclosed trailer

Specification

- Single Axle/Twin Axle

- Length: 1.8~8 meters

- Color: Customizable RAL color series

- Towing system, frame chassis

- Side door, tailgate, ramp door

- LED lights, turning lights

- E track

Why fiberglass enclosed trailers?

In recent years. People have started to gradually shift their attention from steel trailers to fiberglass composites. Because it is clearly recognized that its excellent performance. It not only offers more advantages, but also has a longer service life.

Longer life

Fiberglass enclosed trailers are water and moisture resistant and will not rust or oxidize. The performance can be maintained for a long time. Fiberglass is the perfect material for trailers.

Lightweight

Fiberglass material is made of fiberglass and resin. It has a lightweight nature. Weighs far less than steel and wood trailers. Can be towed by most vehicles during any towing task, regardless of the displacement of 1.5L or 2.0L. and the towing can be done easily. Can be more nimble on narrow and steep highways.

Durable.

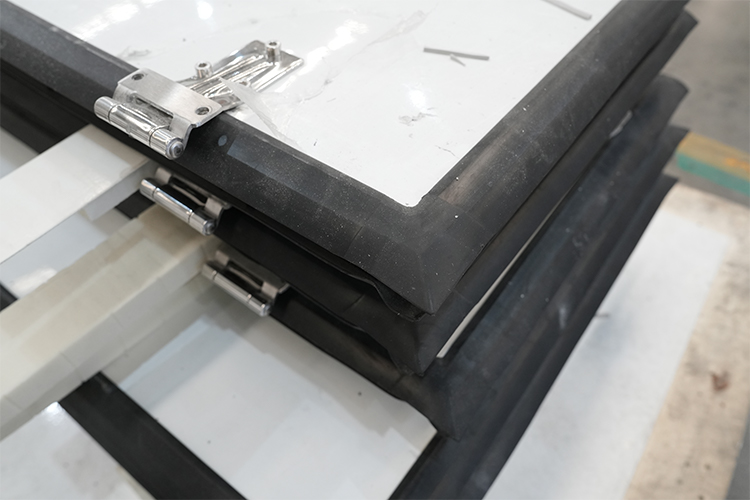

When it comes to steel trailers, although steel is very strong, it is still not as durable as fiberglass. Fiberglass is usually a sandwich panel composite that is laminated with foam to form a fiberglass foam sandwich panel, which has excellent impact resistance and resilience after deformation. It is not prone to scratches.

Thermal insulation performance

Trailers made of fiberglass foam composite panels can have insulating and thermal insulation if XPS or PU foam is used, which can be converted into enclosed insulated trailers, camping trailers and refrigerated trailers.

Composite Materials:

It has a fiberglass skin for better impact resistance. It beats traditional stainless steel and wood panels. It cuts weight by 50% and provides great physical and chemical stability. It provides outstanding rigidity and hardness.

Low Maintenance Costs:

The entire material boasts a long service life and is easy to maintain. Its modular body allows for direct replacement of damaged sections. Using CFRT (Continuous Fiber Reinforced Thermoplastic) can further reduce costs. Repairs can be performed directly using UD tape.

High Customizability:

We accept custom sizing and appearance for fiberglass trailers. You can customize different functions. For example, you can convert to motorcycle trailers, car trailers, or cargo trailers. This suits personal and commercial needs.

FRP Plywood Trailer

Utilizing fiberglass plywood trailer solutions enhances structural integrity, significantly boosting strength. We offer customized fiberglass plywood trailer solutions. FRP plywood offers great impact resistance. Its FRP skin shields the plywood from mold, insect damage, and more. It outperforms traditional wooden structures.

Application

Application of fiberglass enclosed trailer

FAQ

Related Product

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.