What’s PET sandwich panels?

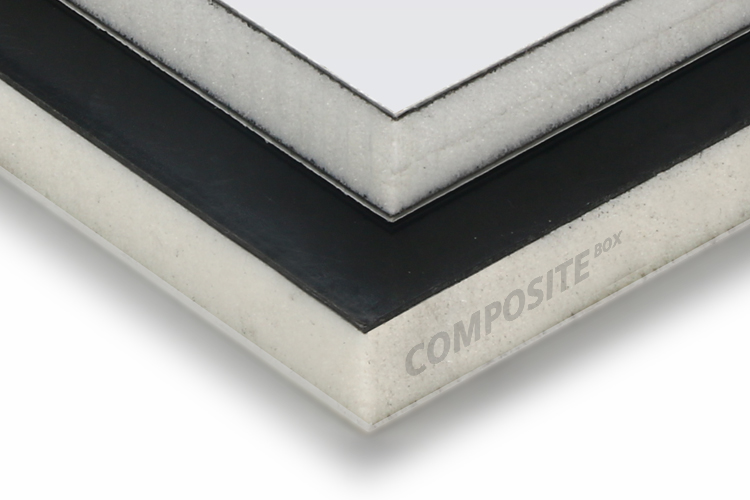

PET sandwich panels are made from 100% recyclable eco-friendly materials. PET is a rigid closed-cell foam similar to XPS foam. It is typically bonded together with FRP and CFRT skins. The density of PET foam ranges from 50 to 250 kg/m³. Thicknesses range from 10 to 150 mm. It is widely used for wall panels and flooring in RVs and truck bodies.

Composite Box es el fabricante de sándwiches de PET de mejor calidad. ¡Ofrecemos producción personalizada de paneles sándwich de PET!

Características

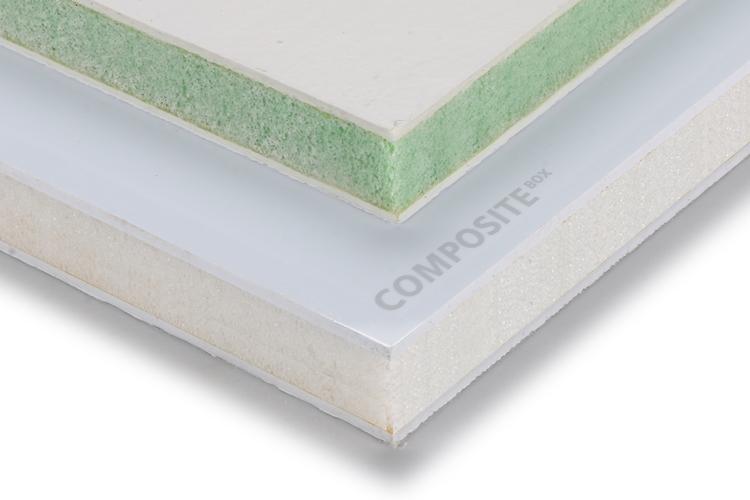

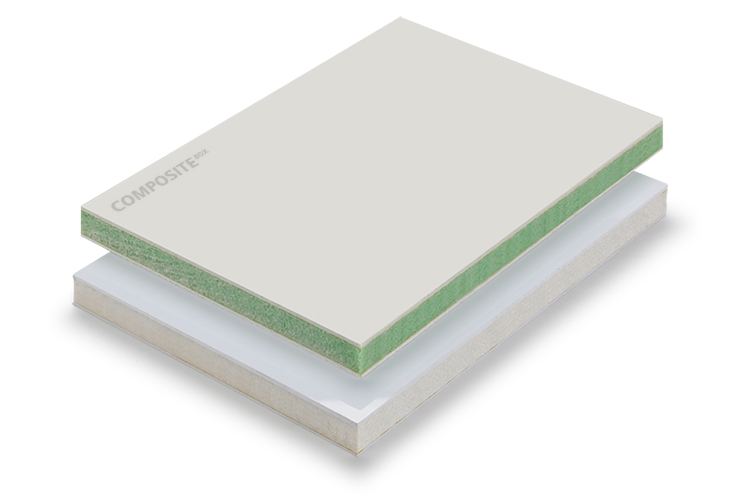

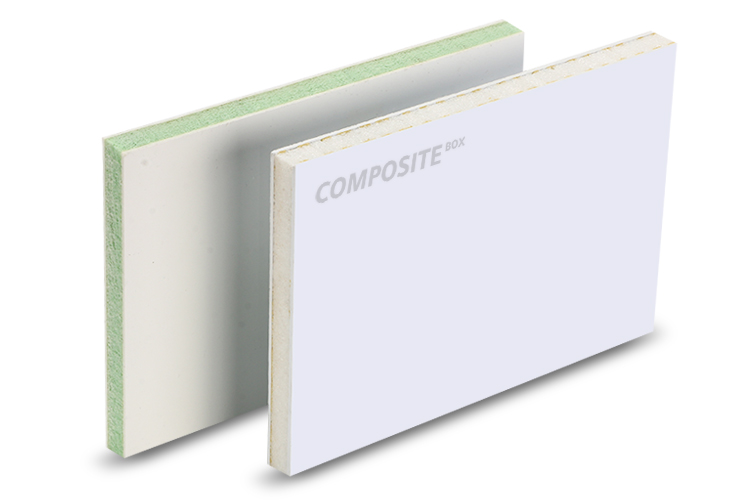

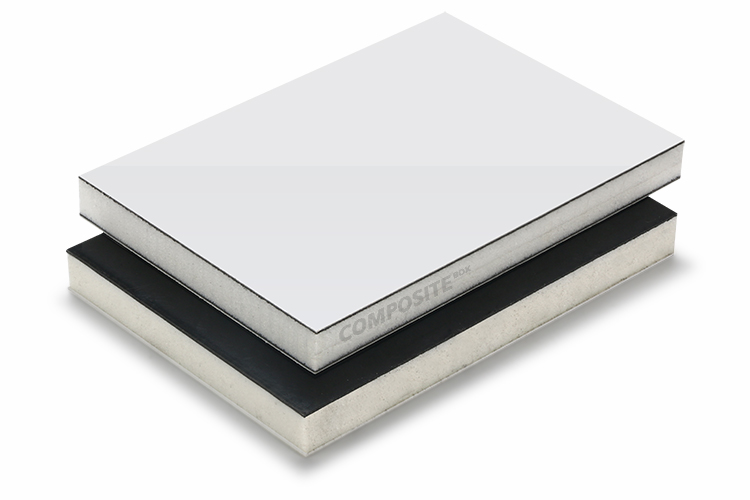

PET sandwich panel is a globally recognized 100% recyclable structural plastic core material made from foamed polyethylene terephthalate (PET). Its surface can be seamlessly laminated with continuous fiber-reinforced thermoplastics (CFRT), glass fiber-reinforced plastics (FRP), carbon fiber, aluminum sheets, or plywood to form lightweight, high-rigidity composite panels.

PET offers outstanding properties including low weight, high strength, zero water absorption, excellent corrosion resistance, and long-term durability, even in harsh wet or marine environments. Compared to traditional timber and aluminum, it is more environmentally friendly, significantly stronger and lighter, and achieves full closed-loop recyclability, making it the superior green core material widely used in refrigerated transport, marine engineering, wind turbine blades, and modern construction.

Obtenga presupuesto gratuito de Paneles sándwich de PET

Catalog

Póngase en contacto con

función

- Ligero: PET density is as low as 50 kg/m³.

- Strength: High-strength material, compressive strength 60-120 MPa

- Reciclable: PET is recyclable plastic; love the environment.

- Low water absorption: PET foam hardly absorbs water.

- Puede procesar fácilmente el cartón PET cortándolo, taladrándolo, fresándolo, etc.

personalización

El panel sándwich de PET admite personalización; estas son nuestras opciones de personalización:

| Artículo | Especificaciones |

|---|---|

| Espesor | 10 mm – 150 mm |

| Anchura | ≤ 3200 mm |

| Longitud | ≤ 12 m |

| Densidad | 25 – 50 kg/m³ |

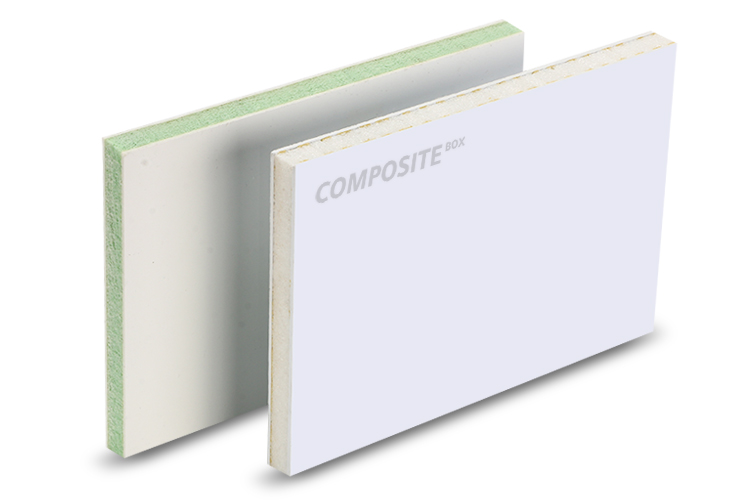

| Color | White, Green (recycled PET) |

| Skin Options | FRP, CFRT, plywood, aluminum, carbon fiber, stainless steel, etc. |

| Surface Coating | Fireproof, anti-slip, anti-UV, anti-bacterial, self-cleaning, etc. |

| Tratamiento | CNC cutting, routing, grooving, drilling, edge sealing; embedded metal/wood inserts available |

| Packaging | Wooden pallet + corner protectors + stretch film; export-standard packaging available |

Aplicación

Los paneles sándwich de PET pueden utilizarse en aplicaciones más ligeras y resistentes gracias a sus propiedades de ligereza, alta resistencia y no absorción. Por ejemplo, en la construcción, furgonetas secas, vehículos recreativos, fabricación y viviendas.

Custom Processing

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

PREGUNTAS FRECUENTES

¿por qué elegirnos?

Satisfacción del cliente

Insistir en productos y servidores de alta calidad, centrados en la experiencia del cliente

Garantía de calidad

Controlamos estrictamente todos los procesos de producción para ofrecer a nuestros clientes una garantía de calidad fiable.

Línea de producción avanzada

La mejor línea de producción del mundo garantiza la precisión y eficacia del producto.

Personalización

Ofrecemos personalización 100%, lo que hace que los pedidos sean menos difíciles.