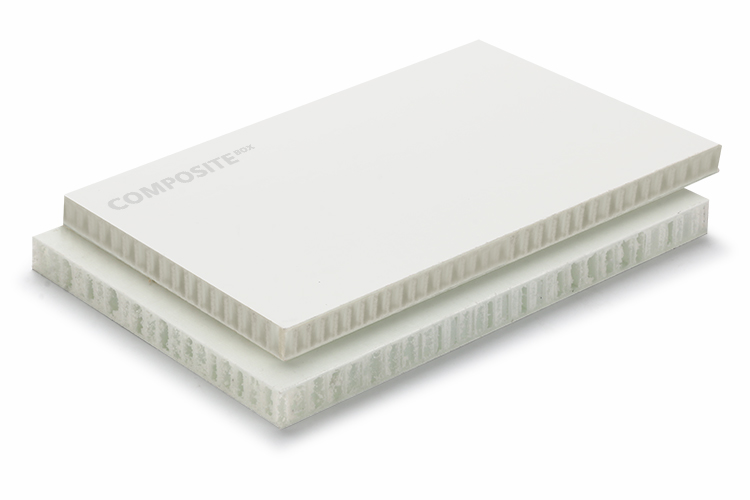

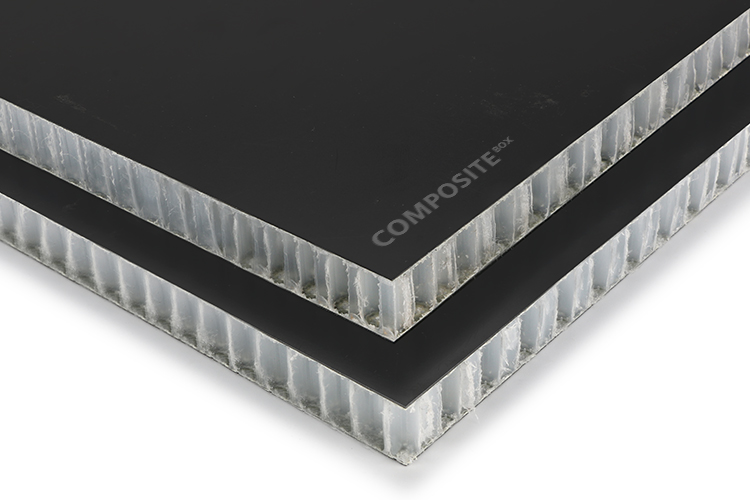

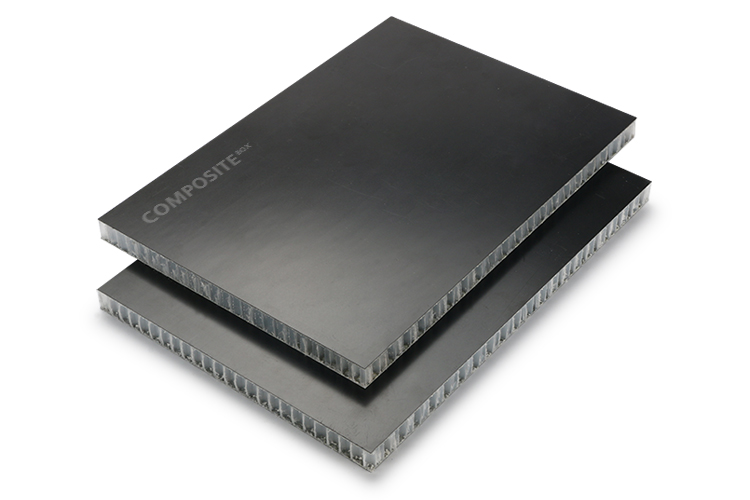

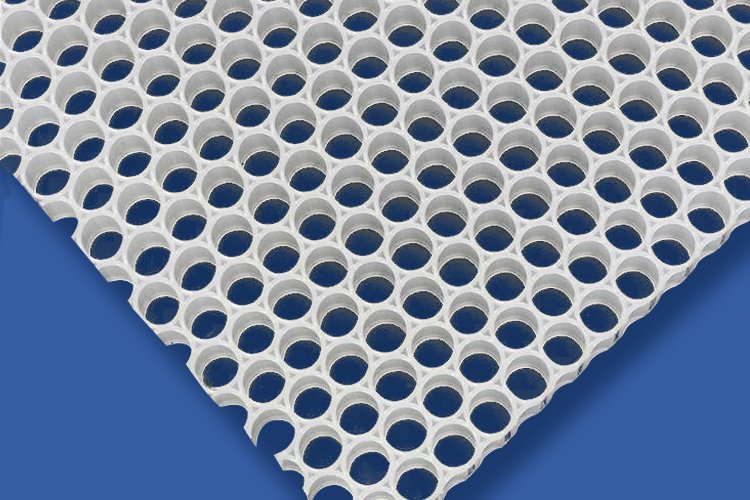

Polypropylene Honeycomb Core

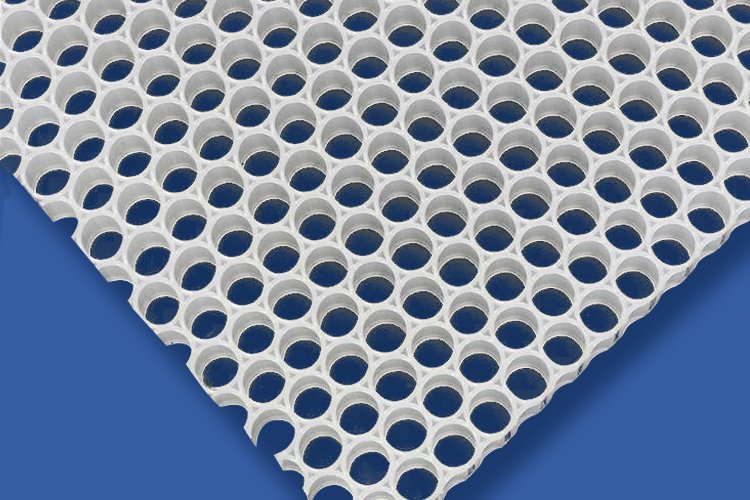

PP honeycomb core is a thermoplastic material with a circular open-cell design. Its density ranges from 58 to 105 kg/m³. It is a plastic sheet material with excellent bending strength. Even though it’s very lightweight, it has great bending strength. This gives it a high strength-to-weight ratio. This plastic sheet material can be laminated with non-woven polyester fiber fabric. It features heat resistance, corrosion resistance, moisture resistance, and sound insulation properties.

Features

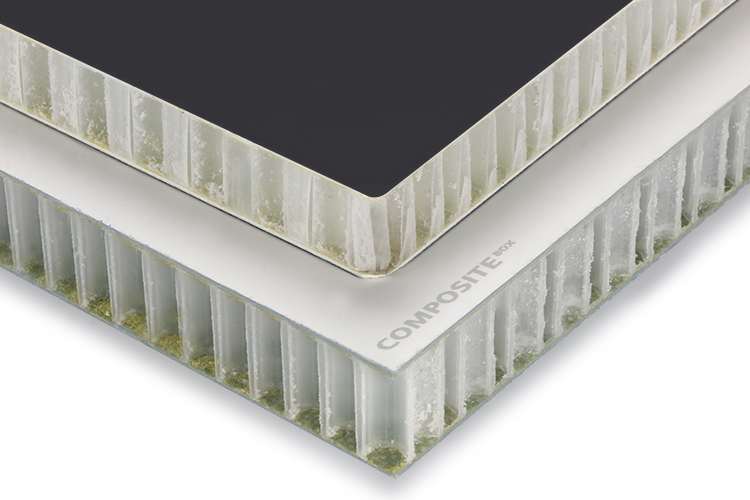

PP honeycomb core is a plastic sheet with a circular open-cell design. It is used as the core material for sandwich panels, providing high strength. It’s often used in box truck bodies, RVs, construction, flooring, and marine applications. We offer maximum lengths of 3.2 meters, maximum widths of 1.6 meters, and thicknesses ranging from 5 mm to 200 mm.

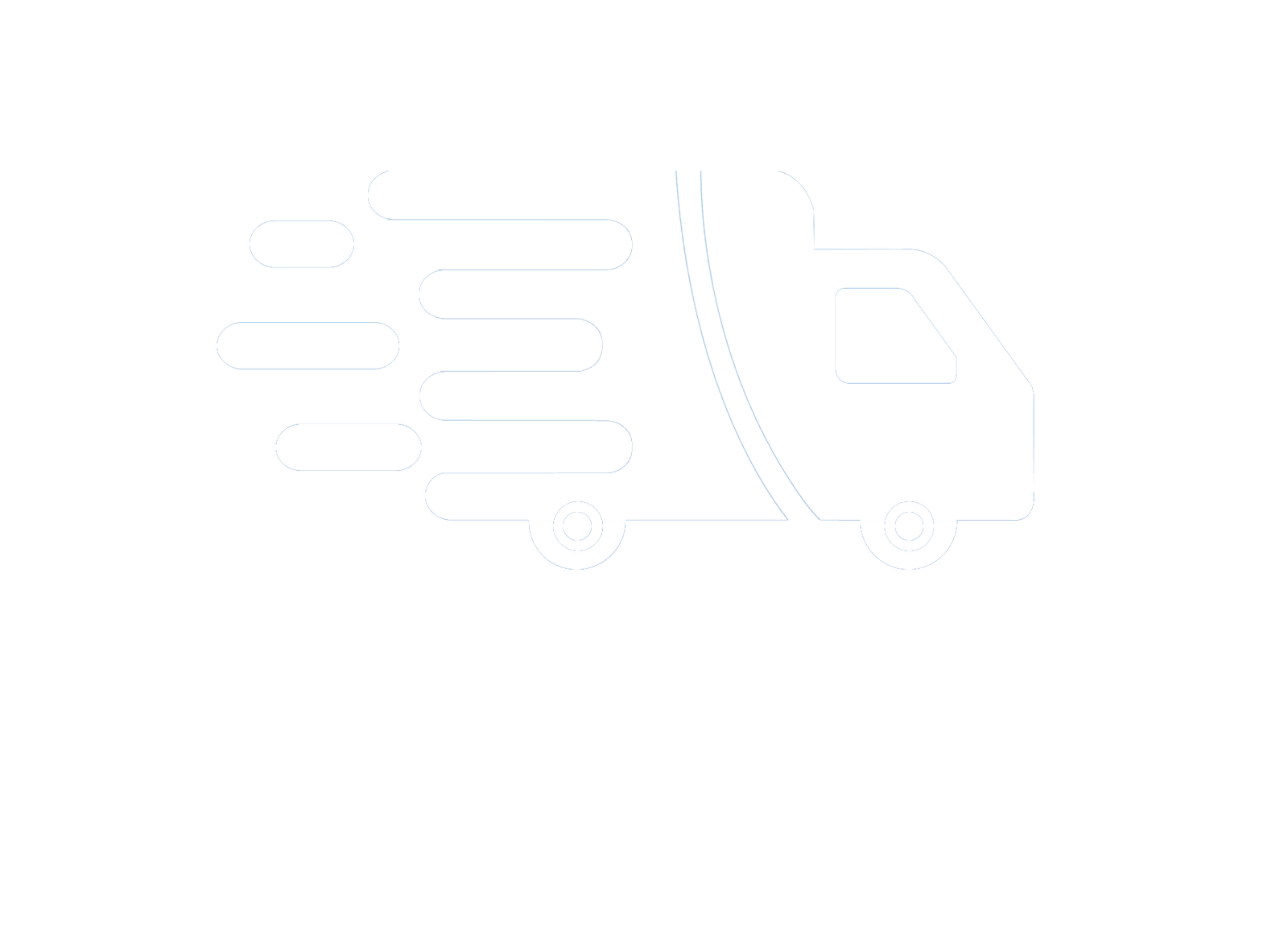

Composite Box provides PP honeycomb cores with non-woven polyester fiber facings. These facings improve adhesion and stop adhesive from penetrating. PP honeycomb cores support thermal forming, vacuum infusion, and other processing methods. They are easy to process, ensuring efficient production. We offer a variety of facings for selection.

Get Free Quote of Polypropylene Honeycomb Core

product Catalog

contact us

Advantages

PP honeycomb cores offer numerous advantages, many of which are unmatched by other core materials. Their strong performance comes from their design, how they are made, and the qualities of PP resin.

High Strength

PP honeycomb cores have great bending resistance. They absorb and spread out external forces, which help reduce impact damage. They can withstand significant impacts and bear heavy loads.

Material Efficiency

In the past, nearly all materials were solid. Under the same strength conditions, PP honeycomb cores use less material. They offer better lightweight performance under higher compressive strength.

Corrosion Resistance:

PP honeycomb cores have a long service life, thanks to their excellent corrosion resistance. They can withstand the corrosion of acids, alkalis, and salts in humid environments while maintaining structural stability. Therefore, they are suitable for applications in low-temperature, marine, and chemical environments.

Recyclability:

PP honeycomb cores are recyclable materials, as polypropylene has a 100% recyclable property. This significantly reduces resource consumption and carbon emissions. PP honeycomb cores are non-toxic and harmless during the recycling process, making them a popular recyclable material.

| Parameter Category | PP6 | PP8 | PP10 | PP12 | PP14 | PP16 | PP18 | Value |

|---|---|---|---|---|---|---|---|---|

| Cell Size (mm) | 6 | 8 | 10 | 12 | 14 | 16 | 18 | – |

| Density (kg/m³) | 87 | 82 | 77 | 72 | 71 | 83 | 85 | – |

| Compressive Strength (MPa) | 1.85 | 1.70 | 1.62 | 1.50 | 1.48 | 1.90 | 1.92 | – |

| Compression Modulus (MPa) | 52.0 | 46.5 | 42.0 | 39.5 | 39.0 | 51.0 | 51.5 | – |

| Shear Strength (MPa) | 0.70 | 0.52 | 0.47 | 0.42 | 0.41 | 0.57 | 0.58 | – |

| Maximum Length | – | – | – | – | – | – | – | 3.2 m |

| Maximum Width | – | – | – | – | – | – | – | 1.6 m |

| Thickness | – | – | – | – | – | – | – | 5mm~200mm |

Applications

PP honeycomb cores are suitable for a wide range of applications.

- RV panels, RV trailers

- Box trucks, moving trucks

- Construction, partition walls, and interior decoration materials

- Industrial railway applications, etc.

- Wind turbine nacelles, solar panel backsheets, etc.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.