Aluminum PET Sandwich Panel Manufacturer

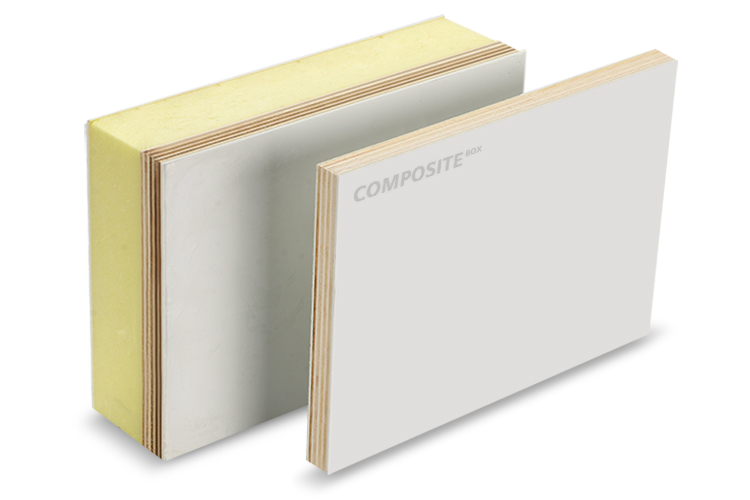

Aluminum PET sandwich panel is a premium composite material that uses recyclable PET foam as core. it is excellent lightweight, durable, insulating composite panel. Refrigerated Meat Transporter” or ”Cold Chain Transporter.

Features

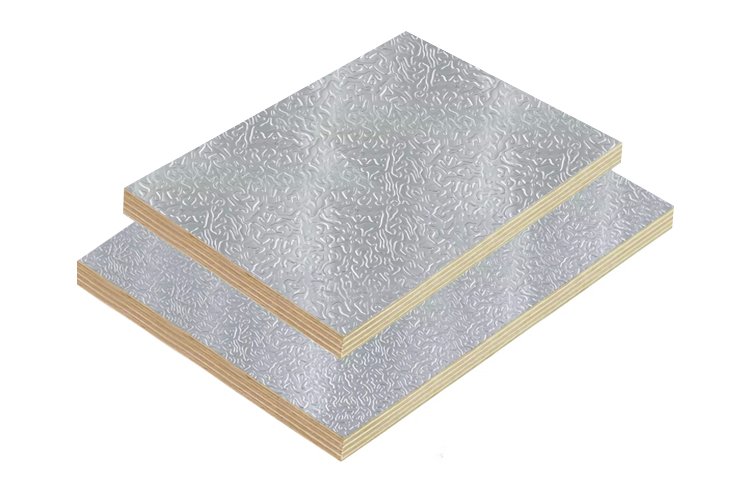

Aluminum PET sandwich panels are laminated using a high pressure vacuum machine, core is made of recyclable PET foam, also called polyethylene terephthalate rigid foam. Using high quality rustproof aluminum alloy SKIN.

Product Advantage:

- Environmentally friendly: both PET foam and aluminum sheet can be recycled, reducing carbon emissions and promoting energy regeneration.

- Strength: Aluminum sheet can withstand huge impacts and is not easily deformed.

- Insulation performance: PET foam has a certain degree of thermal insulation, about 0.03 W/m-K, which can promote good thermal insulation performance.

- Corrosion resistance: Aluminum sheet has excellent corrosion resistance and can resist chemical erosion.

- Lightweight: PET has a low foam density of about 38~90kg/m³.

- Long life: with regular maintenance, the service life can reach 20 years.

Get Free Quote of Insulated Bulkheads

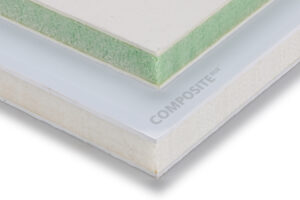

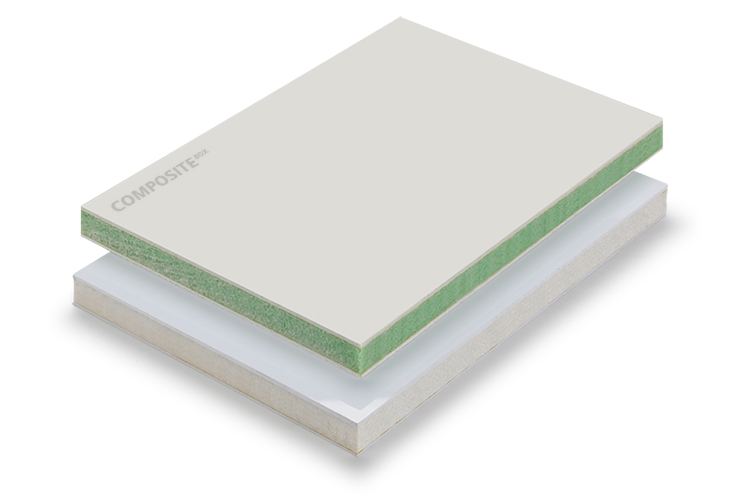

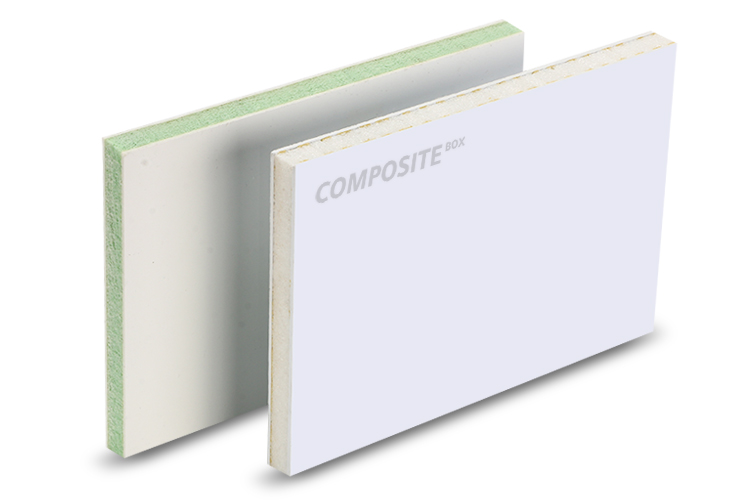

Structure of aluminum PET foam sandwich panels

PET foam

PET foam is a thermoplastic core material with a density of 80~200KG/m³, a recyclable lightweight material with high performance.

aluminum

Application

Aluminum PET foam sandwich panel applications

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.