What’s PET sandwich panels?

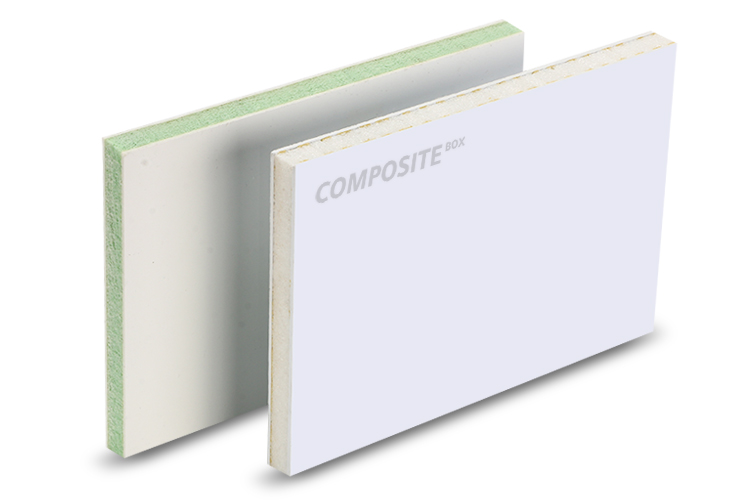

PET sandwich panels are made from 100% recyclable eco-friendly materials. PET is a rigid closed-cell foam similar to XPS foam. It is typically bonded together with FRP and CFRT skins. The density of PET foam ranges from 50 to 250 kg/m³. Thicknesses range from 10 to 150 mm. It is widely used for wall panels and flooring in RVs and truck bodies.

Composite Box is the best quality manufacturer of PET sandwiches. We offer customized production of PET sandwich panels!

Features

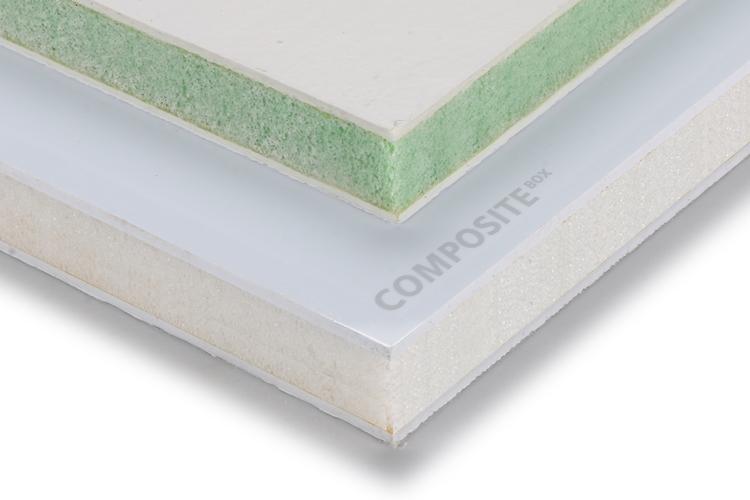

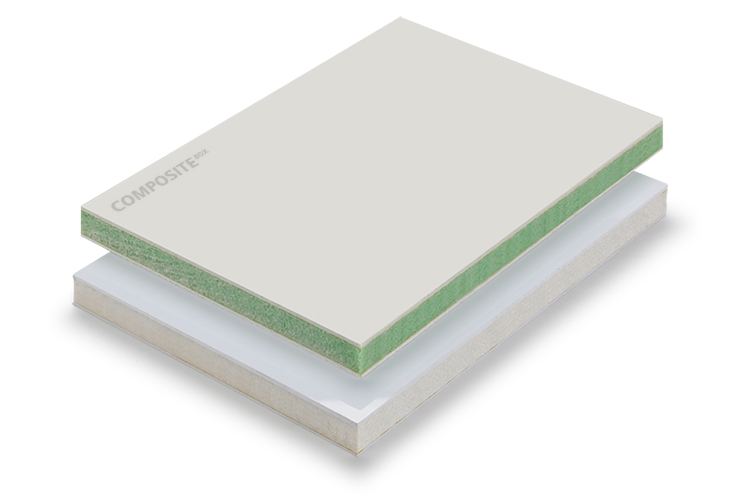

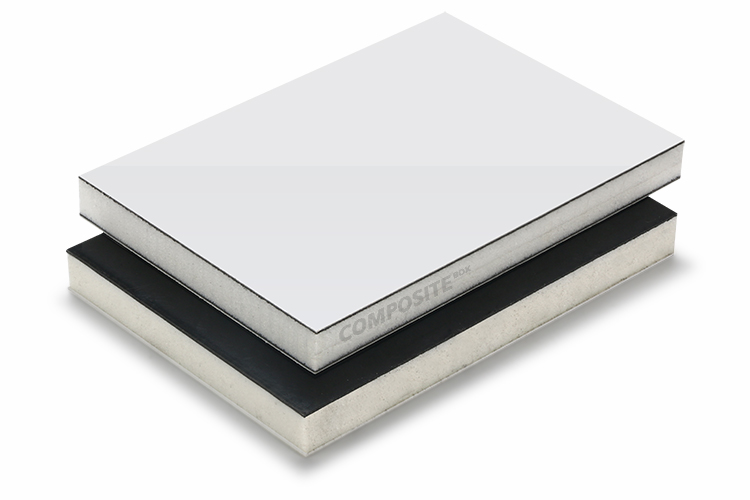

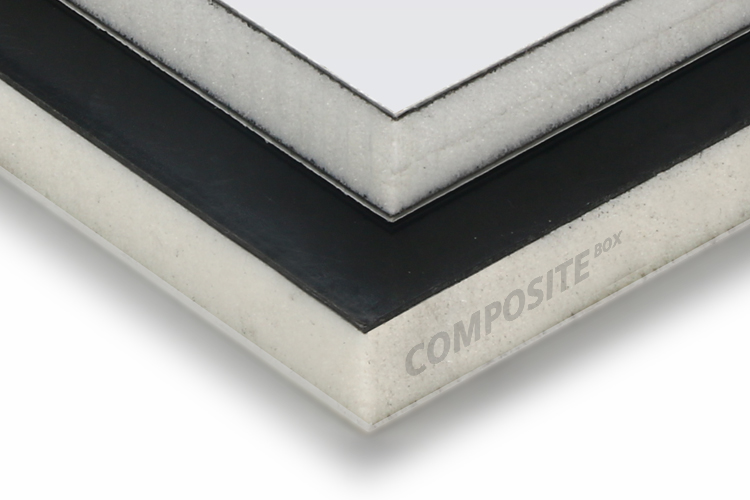

PET sandwich panel is a globally recognized 100% recyclable structural plastic core material made from foamed polyethylene terephthalate (PET). Its surface can be seamlessly laminated with continuous fiber-reinforced thermoplastics (CFRT), glass fiber-reinforced plastics (FRP), carbon fiber, aluminum sheets, or plywood to form lightweight, high-rigidity composite panels.

PET offers outstanding properties including low weight, high strength, zero water absorption, excellent corrosion resistance, and long-term durability, even in harsh wet or marine environments. Compared to traditional timber and aluminum, it is more environmentally friendly, significantly stronger and lighter, and achieves full closed-loop recyclability, making it the superior green core material widely used in refrigerated transport, marine engineering, wind turbine blades, and modern construction.

Get Free Quote of PET sandwich panels

feature

- Lightweight: PET density is as low as 50 kg/m³.

- Strength: High-strength material, compressive strength 60-120 MPa

- Recyclable: PET is recyclable plastic; love the environment.

- Low water absorption: PET foam hardly absorbs water.

- You can easily process PET board by cutting, drilling, milling, etc.

customization

PET sandwich panel supports customization; here are our customization options:

| Item | Specifications |

|---|---|

| Thickness | 10 mm – 150 mm |

| Width | ≤ 3200 mm |

| Length | ≤ 12 m |

| Density | 25 – 50 kg/m³ |

| Color | White, Green (recycled PET) |

| Skin Options | FRP, CFRT, plywood, aluminum, carbon fiber, stainless steel, etc. |

| Surface Coating | Fireproof, anti-slip, anti-UV, anti-bacterial, self-cleaning, etc. |

| Processing | CNC cutting, routing, grooving, drilling, edge sealing; embedded metal/wood inserts available |

| Packaging | Wooden pallet + corner protectors + stretch film; export-standard packaging available |

Application

PET sandwich panels can be used in lighter and stronger applications due to their lightweight, high-strength, and non-absorbent properties. For example, in construction, dry vans, RVs, manufacturing, and housing.

Custom Processing

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

FAQ

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.