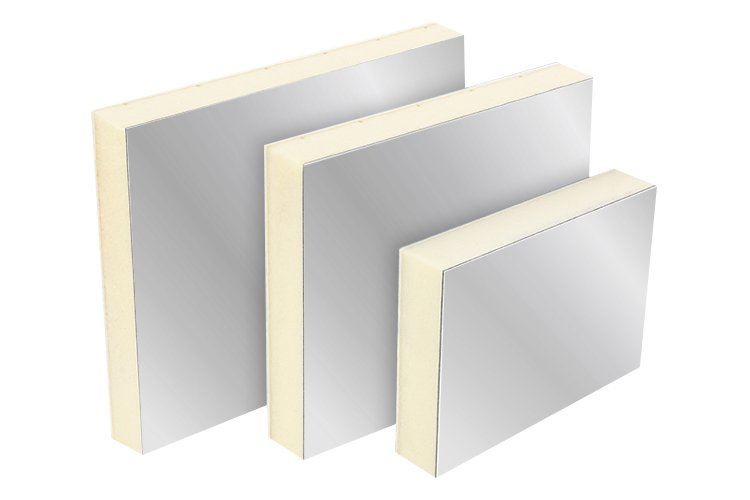

insulated truck Body panels

We are insulated truck panel manufacturers. We customize fiberglass PU/XPS sandwich panels according to your dimensions and chassis requirements. Customizable front panels, roof panels, side panels, rear doors, and side door panels are available. Suitable for refrigerated and insulated cargo compartments. R-values range from 4 to 25, densities from 35 to 60 kg/m³, and thicknesses from 30 to 160 mm. We provide CKD/SKD refrigerated truck body designs.

Features

Sandwich panels with fiberglass skins and insulating foam can enhance insulation performance and minimize heat transfer.Composite Box has many years of experience in manufacturing insulated truck panels. We have world advanced hot press laminating equipment, 5-axis CNC machining machine. We use reinforced steel and aluminum extrusions inside to ensure stability. We can produce lightweight, beautiful, seamless, impact and corrosion resistant truck insulation panels. We are committed to providing efficient, lightweight and durable customized solutions to help the global refrigerated transportation industry. Our products are popular with refrigerated truck dealers around the world.

We offer customization services:

- Offers a wide range of masking materials that can be customized with glossy, matte, or non-slip textures.

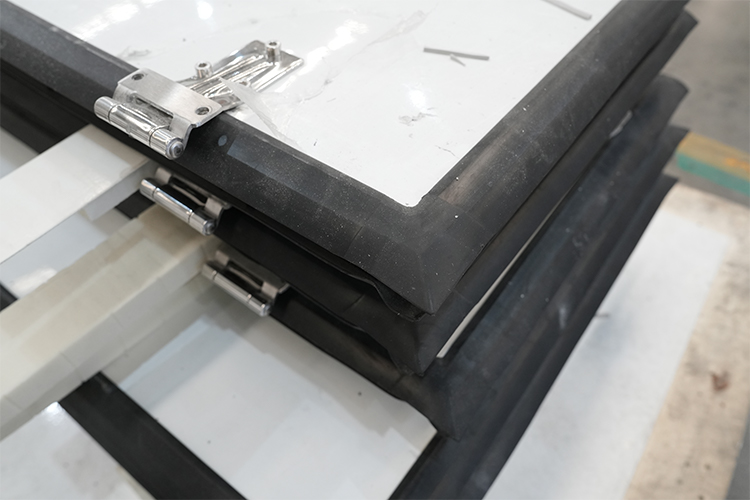

- Accessory support: Latch, hinges, seals and LED lighting system are available. Compatible with CKD/SKD delivery to simplify the assembly process.

- Equipped with hot-press lamination machinery and CNC precision machining lines, along with stringent quality inspection procedures.

Get Free Quote of insulated truck panels

Product advantages

Composite box early to provide foam sandwich panels for refrigerated trucks; after years of research and production, we can provide a complete solution, and in terms of performance, we can do better.

- Cost-effective: in-house production capacity reduces costs.

- Customised kits: up to 16 types of kits available, including floor, front door, locks, etc.

- High strength: using FRP as skin, vacuum high-temperature lamination.

- Long service life: not easy to age, good waterproof performance, long service life

- Easy installation: one person can install it.

- Advanced material: beyond the traditional aluminum truck body panels

- Multiple materials available.

- Our team delivers professional design and premium craftsmanship

- to ensure perfect insulation solutions for truck body panels.

vedio

Selecting Insulation Materials

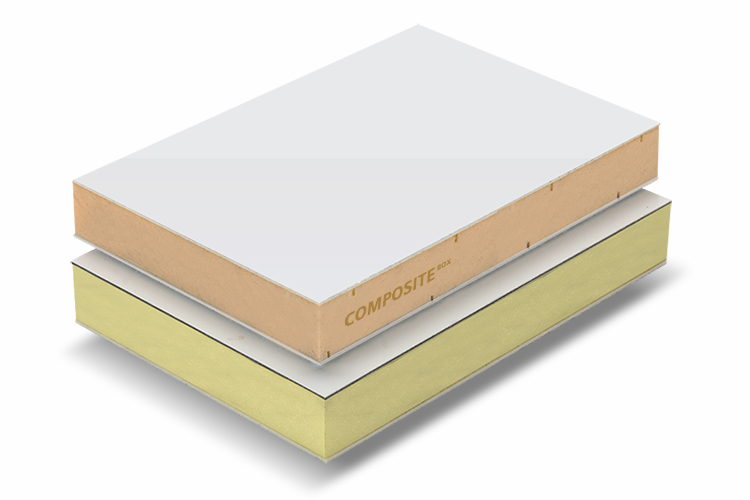

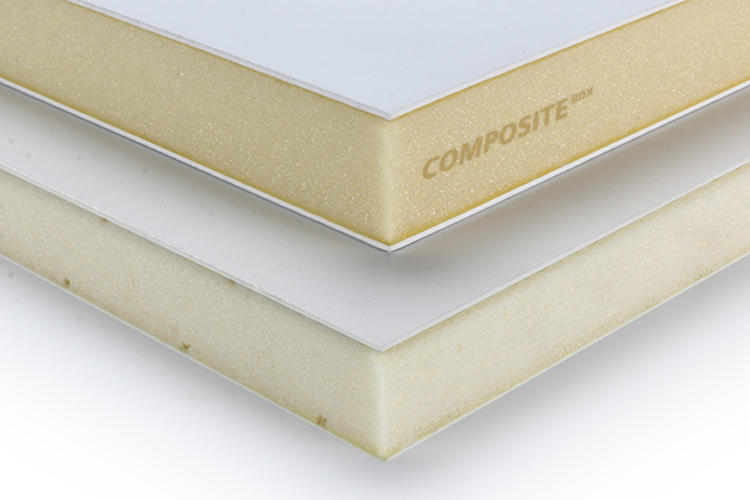

Our insulation foams feature core materials such as XPS, PU, and PP honeycomb, each suited for different skins and applications. Please refer to the table I provided to optimize your cold chain transportation efficiency.

| Core | Cladding | Advantages | Application Scenarios |

|---|---|---|---|

| XPS Foam | FRP/CFRT | Waterproof, Moisture Resistant | Frozen Meat, Agricultural Products |

| PU Foam | Aluminum Panel | Excellent Thermal Insulation | Pharmaceuticals, Dairy Products |

| PP Honeycomb | FRP | Ultra-Light, High Strength | Dry Goods, Multi-Temperature Zones |

Core Features of Customized Insulated Truck Body Panels

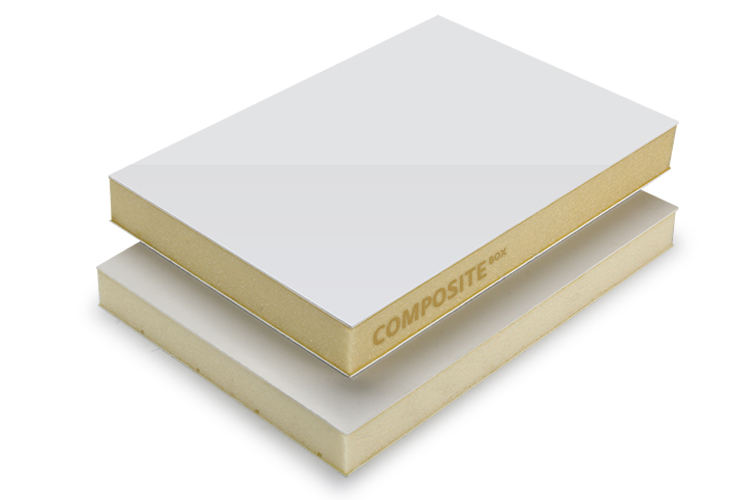

.The core function of insulated truck body panels is efficient thermal insulation, significantly reducing heat transfer to maintain stable interior temperatures and lower refrigeration unit energy consumption. Utilizing polyurethane or XPS foam core materials, thermal conductivity can be as low as 0.022 W/m·K. They effortlessly withstand temperature differentials ranging from -18°C to +20°C. This composite material accommodates various structural frameworks—including wood, aluminum alloy, and FRP—enabling flexible reinforcement according to operational requirements.

Compared to traditional aluminum panels, they reduce weight by over 30%, substantially improving transportation efficiency. Their modular design ensures seamless compatibility with diverse accessories, supporting rapid assembly and mass production.

Why Choose Composite Box?

Composite Box specializes in customized composite panel solutions for refrigerated trucks, offering tailored services that guarantee 100% precise fit regardless of dimensions or chassis type. We start by selecting the right materials for your needs, followed by design, and then proceed to mass production.

Enhanced Benefits

We deliver the most cost-effective quantitative advantages, with solutions that provide long-term benefits. Our insulation panels deliver tangible improvements.

High performance material specifications:

- High-performance material specifications

- fiberglass skin: 0.8mm~5mm

- Insulation foam:XPS (extruded polystyrene) foam, PU (polyurethane)

- Total thickness: 30~120mm

- Width: up to 3.1m

- Length: up to 11.8m

Application

Industrial Applications:

- Refrigerated Transportation

- Frozen Distribution

- Pharmaceutical Logistics

- Food Processing

- Emergency Relief

Also provides sandwich panels for food trucks, sanitary trailer trucks, and horse trucks.

main types of refrigerated trucks:

- Refrigerated Semi-trailers

- Heavy/Medium/Light-duty Refrigerated Trucks

- Refrigerated Vans (e.g., small box trucks)

- Pickup Trucks with Refrigerated Boxes

- Electric & New Energy Refrigerated Trucks

FAQ

material

Related Product

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.