FRP Sheets Manufacturer in china

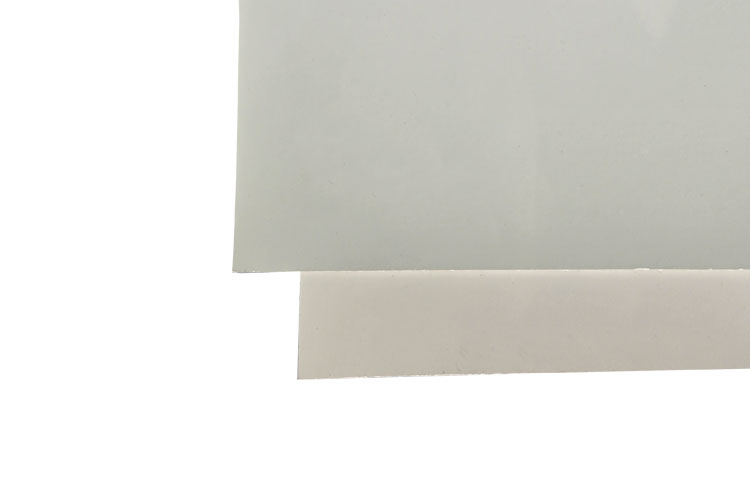

FRP sheet, also called fiberglass reinforced plastic plastici. It is a high-strength, thermoset composite. It is made from glass fibers and polyester resin. It can usually be used in construction, trucks, boats, etc. It is used for skins and is very popular. It is impact-resistant, water-resistant, and lightweight. The composite box uses FRP sheets for peak performance. It is used in many industries. We are a quality manufacturer of FRP.

FRP is available in FR4, UD tape, and continuous fiber panels. We support customized production.

- Thickness 0.4~5 mm, density 1.5~2.0 g/cm³.

- Low thermal conductivity

- Class A fire rating is available.

- Finish: pebbled; smooth surface

- White, matte, beige, gray, black, almond, etc.

Features

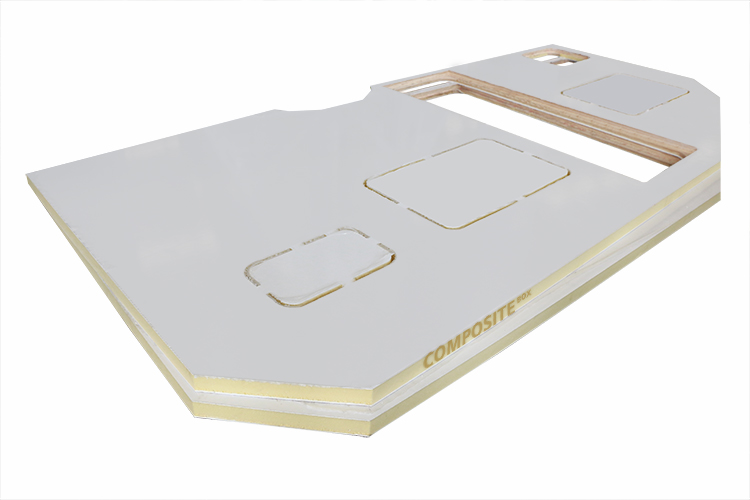

Composite box’s FRP sheet has a high level of performance and has a high profile and important role to play in a variety of industries. not only does FRP perform well, it is available in a variety of finishes and is very easy to install.

FRP has a wide range of properties that make it a good choice for wall panels.

- Corrosion resistance: FRP is resistant to alkaline and acidic environments.

- Beautiful: FRP has a beautiful appearance and is available in a variety of finishes.

- Lightweight: FRP is lightweight, much lighter than aluminum.

- Water and moisture resistant: it can protect the internal structure

- Scratch Resistant: It is very difficult to generate scratches

- Easy to clean: only need water for simple cleaning

So, FRP’s high performance and corrosion resistance make it a top choice. It’s a moisture- and waterproof, high-performance material.

Get Free Quote of FRP Sheets Manufacturer

product Catalog

contact us

FRP physical properties

| Physical Property | Details | Physical Property | Details |

| Density | 1.5 – 2.0 g/cm³ | Tensile Strength | 100 – 300 MPa |

| Flexural Strength | 150 – 400 MPa | Compressive Strength | 100 – 250 MPa |

| Impact Strength | 10 – 50 kJ/m² | Temperature Resistance Range | -40℃ – 120℃ |

| Thermal Expansion Coefficient | (2 – 8)×10⁻⁶/℃ | Thermal Conductivity Coefficient | 0.2 – 0.5 W/(m·K) |

| Flame Retardant Grade | V0 – V2 (varies with different formulations) | Color | Customizable in various colors |

| Thickness | 0.5 – 10 mm (customizable) | Width | 1 – 3.2 m (customizable) |

| Length | Customizable length, generally supplied in rolls | Hardness | Barcol hardness 40 – 60 |

| Surface Finish | Available in smooth, matte and other types |

Related Product

RV fiberglass

RVs and campers use fiberglass, continuous fibers, and laminated FRP sandwich panels to create an RV body that replaces the traditional aluminum foam sandwich body, making it lighter, easier to maintain, and more efficient to drive.

Refrigerated truck box

Can be used to manufacture refrigerated box truck bodies and has good heat insulation and thermal insulation effects, widely used in cold storage and freezing; FRP is very suitable for the production of refrigerated truck bodies.

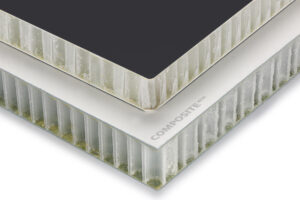

fiberglass foam sandwich

It can be used to produce fiberglass foam sandwich panels; the core can use XPS, PU, PET, PVC, and other foams. You can also use plywood, PP honeycomb, and other materials as the core, which can enhance the performance of the FRP panel.

Application

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.