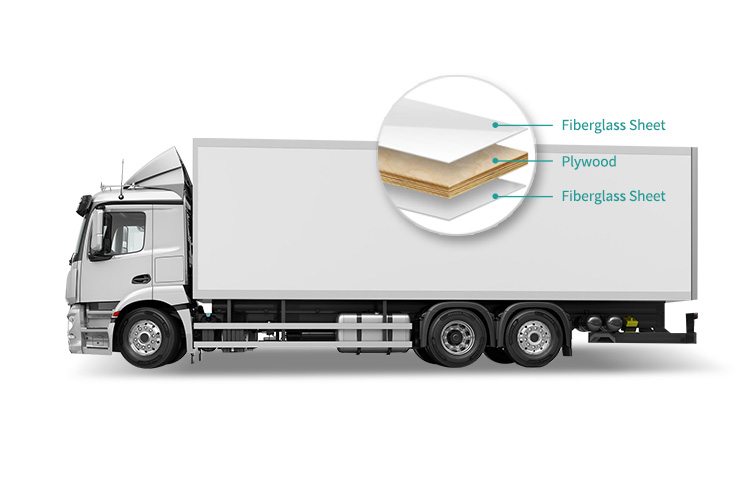

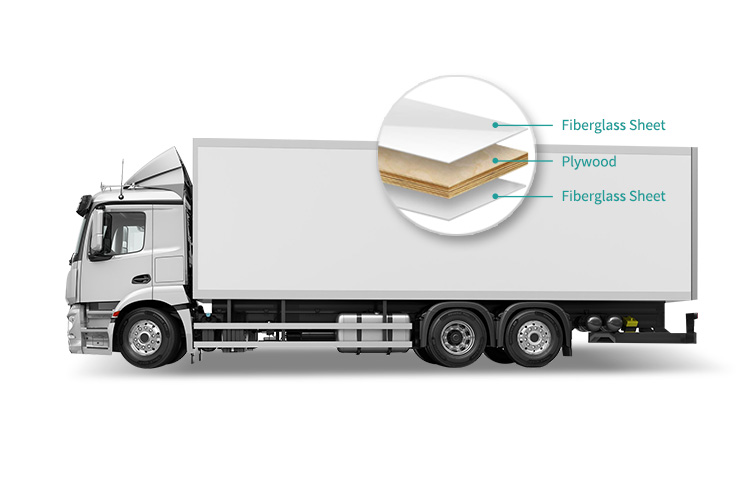

Fiberglass Plywood Panels For Truck

Specifically designed for freight trailers and small freight trailers.

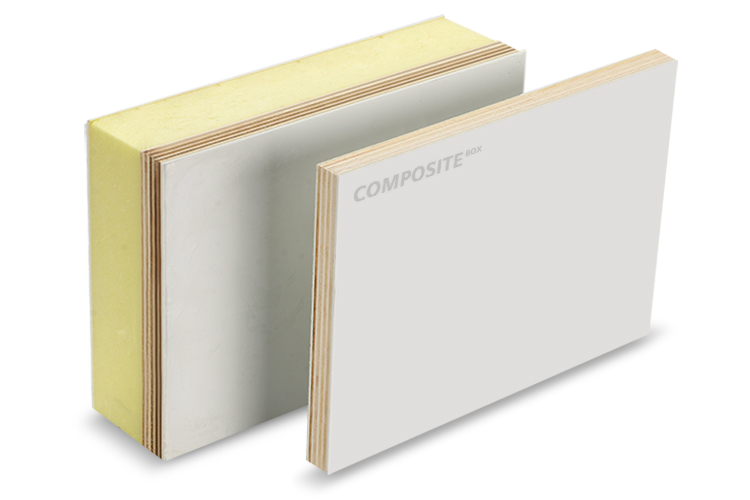

We specialize in the production of fiberglass plywood panels for truck bodies. We offer optimal material utilization. The plywood is composed of multiple layers of thin wood, with the growth rings arranged perpendicular to each other. The wood is naturally air-dried for over eight years, ensuring a moisture content of less than 6%. This minimizes the risk of deformation in the future.Can be used to manufacture cargo truck bodies and dry freight bodies.

Features

Fiberglass plywood panels for truck bodies. It is a standard custom material for trucks and can only be used for truck bodies.Designed specifically for truck bodies. Features a 1.5mm fiberglass (glass-reinforced plastic) outer layer. Plywood thickness ranges from 10mm to 40mm. Marine-grade waterproof plywood is used. Constructed by laminating 8 to 20 layers of thin wood with adhesive. It can be used as the front panel, side panels, floor, roof, and doors of truck bodies. Our solution maximizes the performance and application range of plywood.

Get Free Quote of Fiberglass Plywood Panels For Truck

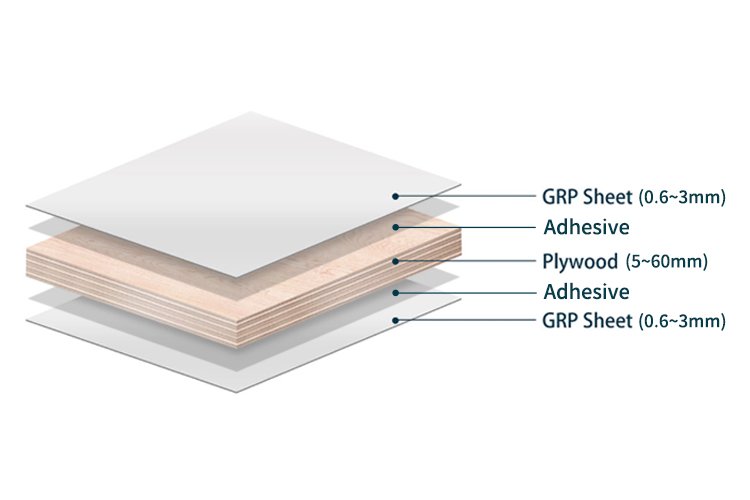

FRP Plywood Panels Structure for Truck Bodies

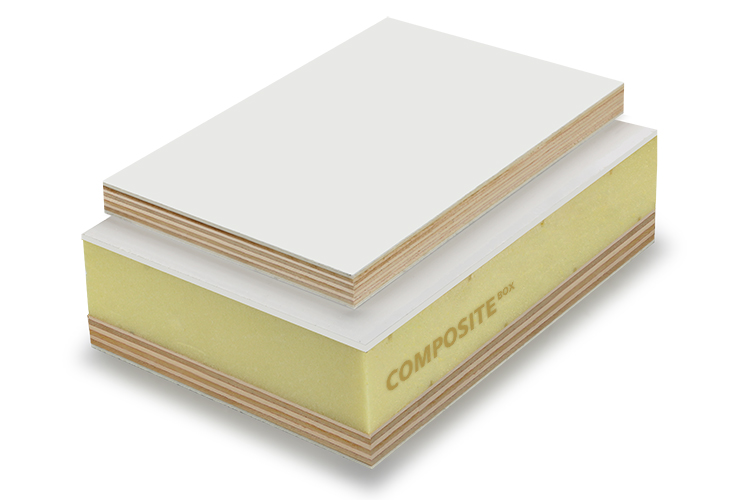

It consists of two layers of 1.5mm FRP sheets as the outer surfaces. The core layer uses marine-grade plywood (birch, pine, poplar, eucalyptus, oak, etc.). It offers corrosion resistance, impact resistance, ease of processing, and lightweight properties. The layers are bonded together using non-adhesive vacuum high-pressure lamination.

Comparison with Pure Plywood.Fiberglass skin can make up for its shortcomings. It can improve waterproof properties and surface appearance. It can also prevent fires.

Features

Fiberglass plywood panels are very suitable for transporting goods that do not have temperature requirements. It also has many other features.

Advantages

- Lightweight

- Low cost

- Durable

- Waterproof

- Moisture-resistant

- Corrosion-resistant

- High impact resistance

Applications

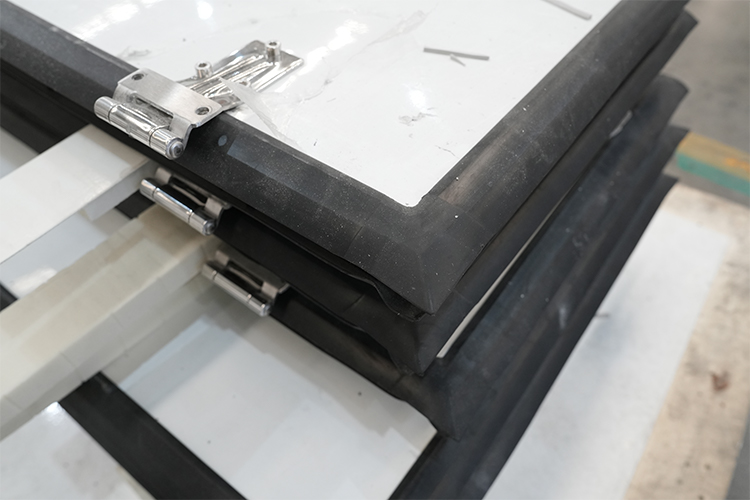

Specifically designed for freight truck bodies: side panels, front panels, roof panels, truck floors, side panels, and floor panels.

Can be used for producing small freight trailer panels.

why choose us?

Our fiberglass plywood is specially designed for freight trucks and trailers. It uses a vacuum high-pressure composite process to combine a 1.5 mm fiberglass surface layer with multiple layers of marine-grade plywood, combining the strength of metal with the lightweight advantages of wood. It provides industry-leading moisture resistance, impact strength, and corrosion resistance. At the same time, its standardized modular design supports quick installation and replacement, helping customers reduce maintenance costs by 30%. It is the ideal choice for modern and efficient logistics and transportation.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.