Fiberglass PET foam panels manufacturer in china

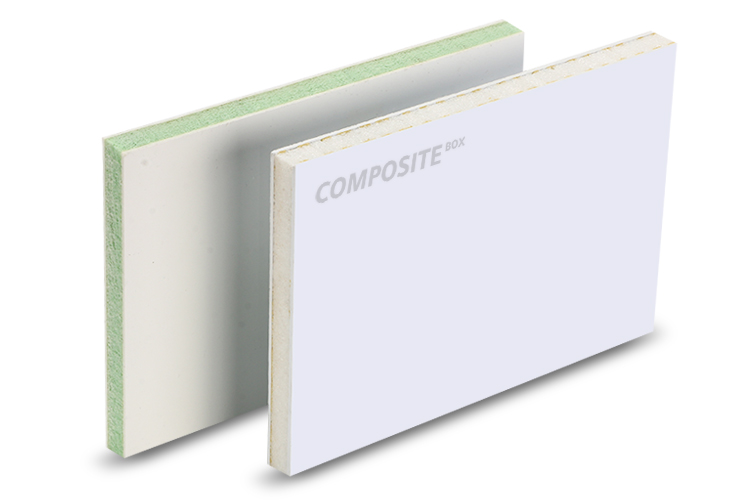

Fiberglass PET foam panels are a new type of environmentally friendly composite material; the PET core’s recyclability helps reduce pollution in the environment. The colors are white or green. It is a high-strength composite material that can be used for wall panels, flooring, and partition walls with excellent load-bearing capacity.

Composite Box is the best FRP PET sandwich panel manufacturer; we support OEM customization, CNC machining, embedded reinforcement, and so on.

Features

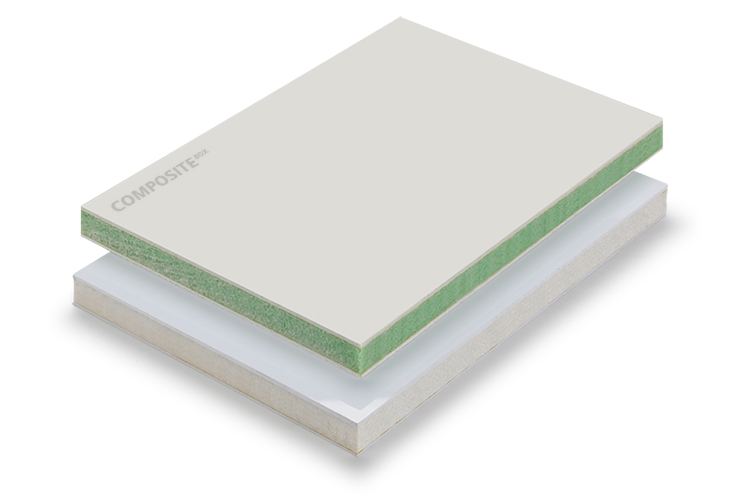

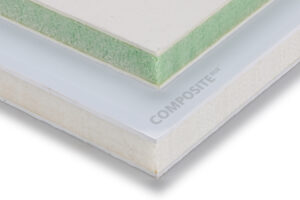

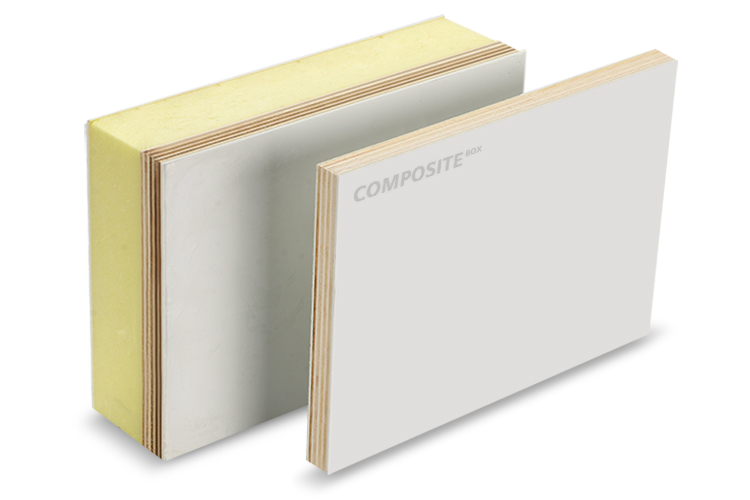

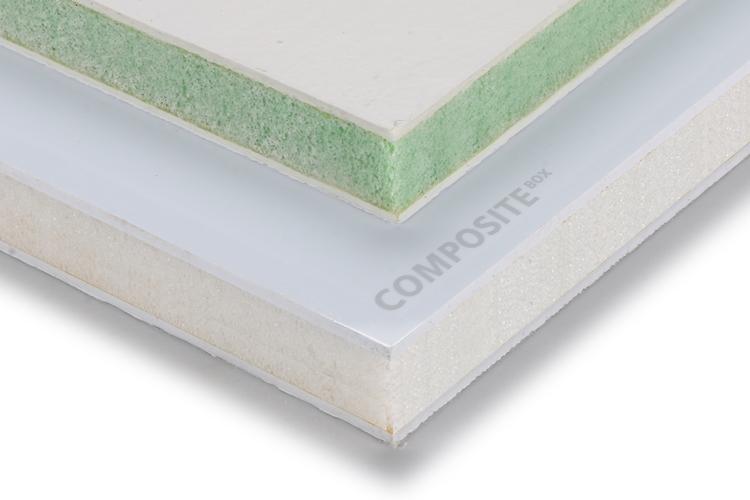

Structure: FRP sheet for the skin, PET foam core for the core.

Composite-box manufacturer has been specializing in the production of fiberglass PET foam panels for 20 years. PET is a recyclable and environmentally friendly foam core. Interestingly, the recycled PET foam core is green in color. Our diverse range of products is sure to be ideal for you.

Our products are bonded using environmentally friendly adhesives and laminated using vacuum and high-pressure equipment. This ensures that they will not crack and de-glue during use. If you need to use them for special applications or high-strength scenarios, they can be embedded with reinforced steel, FRP, aluminum profiles, plywood, etc. to be more robust. Our products have a long service life, and the exterior treatment uses a film that protects the FRP skin, and the exterior can also be added with flame retardant and anti-UV agents to improve durability. The working temperature can reach -40℃ to 130℃.

Get Free Quote of Fiberglass PET foam panels manufacturer in china

Product Advantage

Structure of fiberglass PET foam sandwich panels

PET foam

PET foam is a thermoplastic core material with a density of 80~200KG/m³, a recyclable lightweight material with high performance.

FRP sheet

PET (polyethylene terephthalate) is chemically stable, is recognized worldwide as an environmentally friendly recyclable material, consists of a closed cell structure, is waterproof and moisture resistant, and is the ideal material for many applications.

Application of fiberglass PET foam panel

FRP PET foam sandwich panels are used where lightweight, high strength is needed. These include:

Technical Parameters

FRP Fiberglass PET Foam Panels Specifications

| Property | Specification |

|---|---|

| Thickness | 10–140 mm |

| Width | ≤3000 mm |

| Length | ≤12000 mm |

| Core Density | 60–300 kg/m³ |

| Skin Material | High-performance FRP sheet |

| Core Material | PET foam (white or green, recyclable) |

| Skin Color | Available in RAL colors |

| Bonding Process | Environmentally friendly adhesive, vacuum high-pressure lamination |

| Working Temperature | -40°C to 130°C |

| Customization Options | Embedded reinforcements (steel, FRP, aluminum, plywood, etc.) |

| Surface Treatment | Protective film, flame retardants, anti-UV agents |

| Durability | Impact-resistant, waterproof, moisture-resistant |

Custom Processing

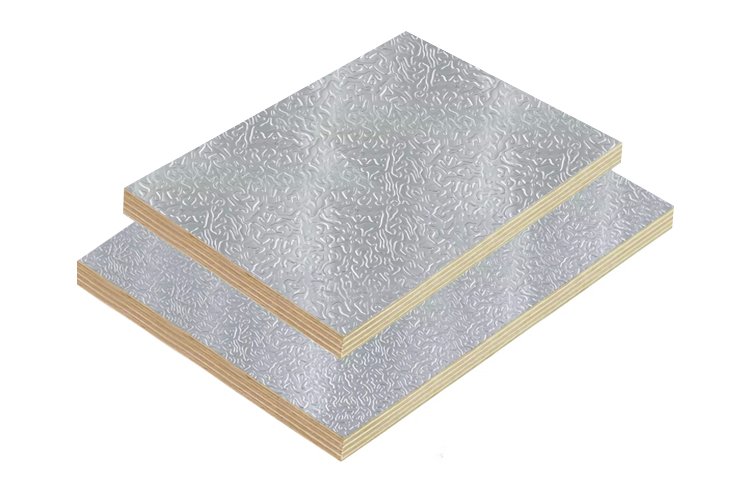

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

FAQ

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.