Box truck body panels manufacturer & supplier

Sandwich panels for box truck bodies are made up of fiberglass panels and filler materials. Sandwich panels help make strong and durable box truck bodies. The market prefers fiberglass skins because they are strong, waterproof, and long-lasting. Plus, they are over 30% lighter than steel and aluminum panels, which makes them a popular choice for lightweight materials. The internal core uses foam (XPS, PU, PET), plywood, and PP honeycomb. This composite material makes the truck body lighter and more versatile.

We design fiberglass sandwich panels. We also offer truck body design, help with material selection, and manage mass production along with other services. Our experts establish a one-on-one relationship with you.

Features

Composite Box focuses on refrigerated and dry freight trucks. We handle SKD and CKD deliveries. As a sandwich panel manufacturer, we also design truck bodies. Our multiple production lines give us cost advantages. We use CNC machining and one-piece molding technology. Our advanced techniques guarantee perfectly flat fiberglass plywood panels for truck with strict quality control. We also offer various coatings and processes for better performance.

We use lightweight, high-performance materials. They can replace expensive and inefficient options like aluminum and steel panels. We can improve your economic efficiency. We are the most professional manufacturer of truck body sandwich panels. Choosing us is the beginning of your growth.

We have a multilingual sales team. They speak English, Spanish, French, Japanese, Korean, and more. This way, we can work together without language barriers.

Get Free Quote of Box truck body panels

product Catalog

contact us

Our Advantages

- Lightweight: 40%–50% lighter than traditional metal panels, saving fuel costs.

- High strength: impact resistance, corrosion resistance, and prolonged service life.

- Thermal insulation is especially suitable for refrigerated trucks.

- Easy to assemble: supports CKD/SKD form and reduces manufacturing complexity.

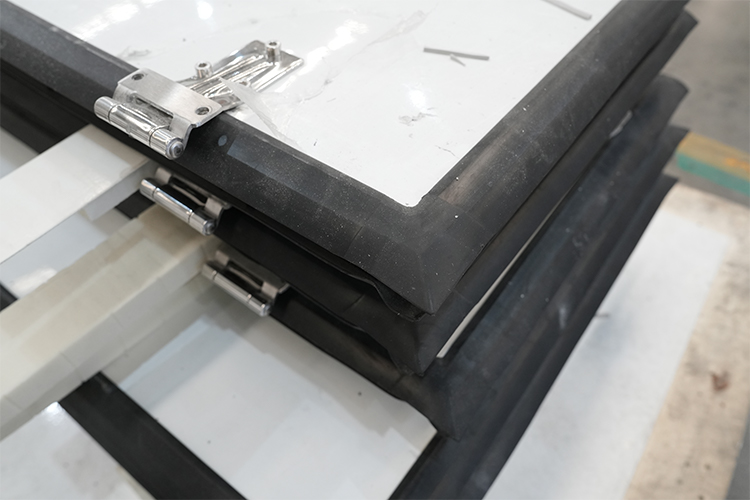

Box truck body sandwich panel construction

Adopting insulated truck body panels made from fiberglass sheets or continuous fibers as skin.

- FRP skin, or fiberglass reinforced panels, is made from strong fiberglass and resin. It offers corrosion resistance and UV protection, among other benefits. Most importantly, it has a lifespan of more than 15 years, thanks to its high strength and non-rusting benefits. It is suitable for long-term outdoor use and does not age easily. High impact resistance makes it suitable for use in the manufacture of heavy-duty box truck bodies.

Use of foam as internal filler: Rigid XPS foam, PU foam, PET foam, and PVC foam.

- XPS foam offers great thermal and heat insulation. It works well for refrigerated trucks and is also highly waterproof.

- PU foam: super insulation performance, corrosion resistance, lightweight. It is the best thermal insulation foam.

- PET Foam: PET foam is lightweight and recyclable. It saves costs and protects the environment.

- PVC Foam: PVC Foam has high strength performance, high loading force, and is easy to process.

- Marine Plywood:

Marine plywood is a waterproof, high-strength material that usually consists of more than 5 layers of thin wood. It is bonded with a waterproof adhesive. It is very strong and waterproof, does not corrode easily, and has an antioxidant coating on the surface. - PP Honeycomb Panel:

A honeycomb structure made from polypropylene is lightweight but strong. It resists impacts and is recyclable, making it eco-friendly. It is very suitable for use in combination with fiberglass.

Parameters

| Material | Density (kg/m³) | Thermal Conductivity (W/(m·K)) | Strength (kPa/MPa) | Water Absorption | Temp (°C) |

|---|---|---|---|---|---|

| XPS Foam | 28-45 | 0.028-0.035 | 200-700 kPa | <1% | -50 to 75 |

| PU Foam | 30-50 | 0.020-0.025 | 150-300 kPa | <2% | -60 to 100 |

| PET Foam | 60-130 | 0.035-0.040 | 500-1000 kPa | <1.5% | -40 to 120 |

| PVC Foam | 50-150 | 0.030-0.045 | 800-1500 kPa | <1% | -20 to 80 |

| Marine Plywood | 500-700 | – | 40-60 MPa | <5% | – |

| PP Honeycomb | 80-120 | – | 1-3 MPa | <0.5% | -20 to 80 |

application

Box truck body panels of application

- Reefer Body

Great for making reefer bodies, this insulation foam improves performance. It helps maintain a stable temperature of -20 ℃. It can be used for the transportation of frozen meat, ice cream, medicine, etc. - Dry freight trucks

Dry freight trucks are often made from PET foam and PP honeycomb boards. They transport furniture, ambient goods, and packaged items. - Trailer Body

Sandwich panels are great for making small trailers and semi-trailers. They need an internal reinforcement structure. The thickness of the panels varies based on the required strength.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.