What Are Sandwich Panel? You Should Know

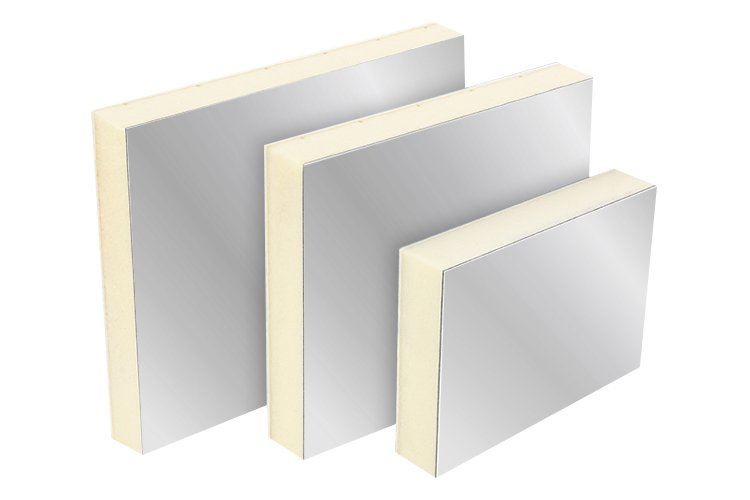

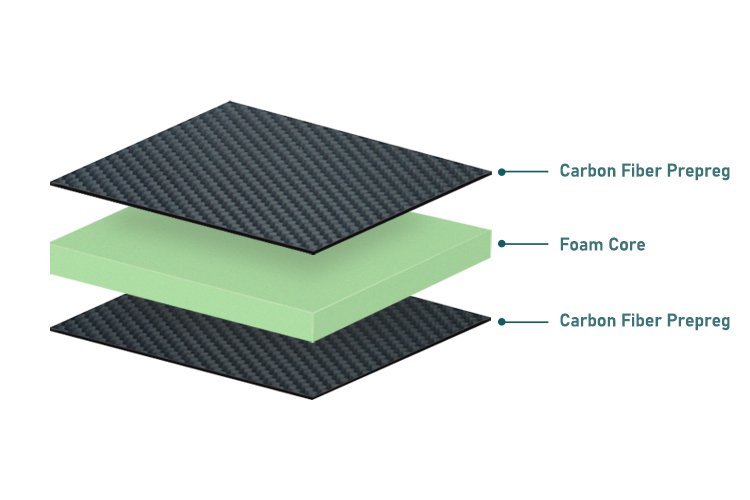

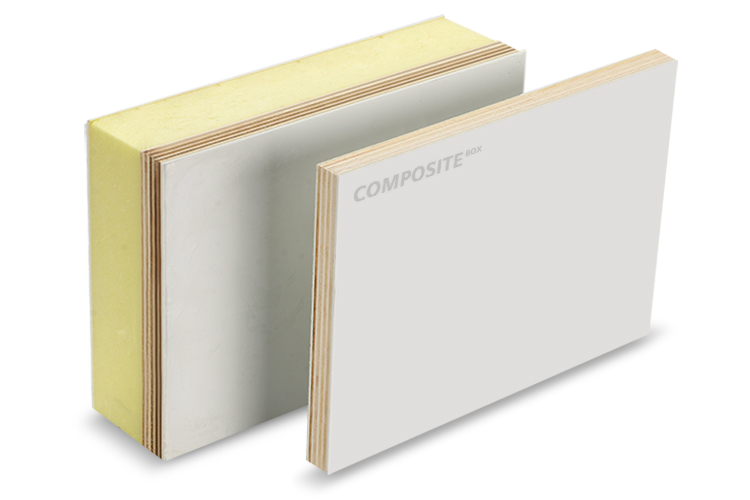

Sandwich panels are high-performance, multi-layer construction materials that typically consist of a skin, core, and adhesive. They usually consist of fiberglass-reinforced plastic, rigid foam, mineral wool, and a honeycomb core. Sandwich panels usually provide thermal and acoustic insulation, high strength, and other properties. They can be used in various applications such as construction, freight cars, modular buildings, insulation applications, etc.

What types of sandwich panels are available?

The types of sandwich panels are mainly differentiated by material, with different skins and cores, offering different roles and properties. However, they all have soundproofing and insulation properties. They usually differ in compression, thermal insulation, cost, etc.

Outer skin:

The outer skin of the sandwich panel is mainly for the sandwich panel to play a protective role, there is a decorative role, that can improve the aesthetic performance. Skin in the external layer needs to use high-performance materials, can isolate the erosion of rain and moisture resistance, and must have impact resistance. Common sandwich panel skins include:

- Fiberglass reinforced plastic (FRP): FRP, as the skin of the sandwich panel, is very strong, has excellent impact and friction resistance, has good durability, is suitable for rainy areas and humid environments, and is not easy to corrode.

- CFRT (Continuous Fiber Plastic): CFRT is also called new continuous fiber plastic, mainly originated from China, its performance is close to that of FRP. However, CFRT has good resilience, can be changed back to its original performance after impact, is easy to repair, and has a lower cost.

- Pre-painted galvanized steel: can keep good work in bad weather, excellent corrosion resistance, beautiful surface, good processing performance.

- Aluminum skin: lightweight, good corrosion resistance, good thermal conductivity, and metallic luster.

- Stainless steel: high strength, good corrosion resistance, low maintenance cost, high-temperature resistance.

- PP anti-slip skin: good anti-slip performance, suitable for flooring and wet places, good toughness.

Currently, on the market, the use of fiberglass as a skin accounted for the main, whether it is used for truck boxes, or exterior walls very suitable.

Core material:

The core material is the center of the main sandwich panel, the main role is to enhance the strength of the sandwich panel, thermal insulation, insulation, fire performance, etc. Commonly seen core materials include:

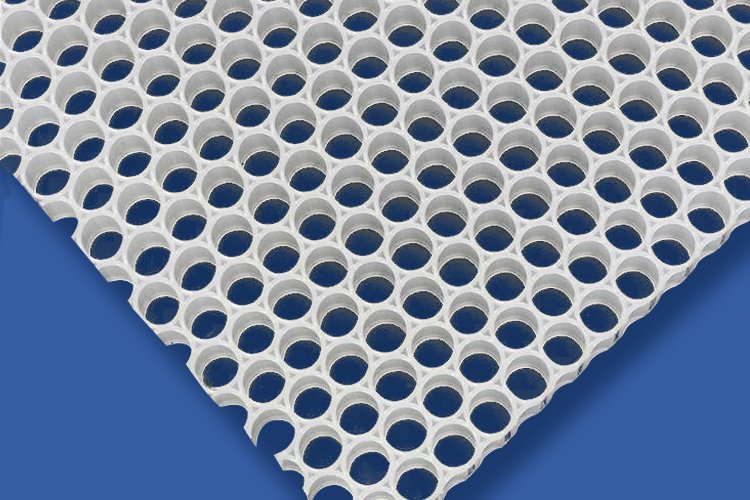

- PP honeycomb core: made of polypropylene, the honeycomb core structure, has good impact resistance characteristics, and high strength.

- XPS Foam: i.e. Extruded Polystyrene Foam, has excellent thermal insulation properties, closed cell structure, and good thermal insulation performance, commonly used in thermal insulation applications such as refrigerated truck body.

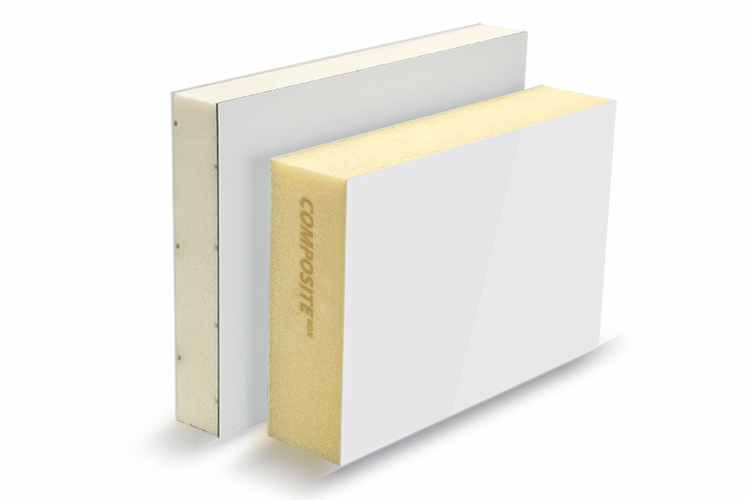

- PU Foam: Polyurethane foam is a popular insulation material and has excellent vibration-damping and soundproofing properties, and its hardness can be adjusted over a wide range.

- PET FOAM: PET foam is an environmentally friendly recyclable foam core with good strength and stiffness.

- PVC FOAM: Easy to process, low density, and good performance.

Bonding layer:

The sandwich panel adhesive layer is used to bond the panel and the core material, is in the key part, to ensure that they are tightly combined, and can play the overall performance, can improve the sealing, stability, and anti-peeling ability of the sandwich panel. The following types of glue are usually used.

- Polyurethane glue

- Epoxy glues

- Acrylate glue

What are the benefits of sandwich panels?

Sandwich panels have so many advantages that they have been able to become such a popular structural material around the world. The main advantages are as follows:

- Good thermal insulation:Low thermal conductivity is achieved through a multi-layer structure using insulating foam.

- High strength: sandwich panels have better impact resistance than traditional aluminum panels, formwork

- Easy to install: sandwich panels are very simple to connect and modularize.

- Low cost: sandwich panels can now be mass-produced and save material without waste.

- Multi-functional: Sandwich panels can be used in a variety of industries and fulfill many functions.

What are sandwich panels used for?

Sandwich panels for truck body and RV

Sandwich panels can be used as a high-quality external structure for truck box bodies and RV bodies, they provide good thermal and acoustic insulation and have low thermal conductivity, and in refrigerated truck body applications, refrigerated sandwich panels are used, usually fiberglass XPS foam panels.

Refrigerated panels and insulation panels

In addition to being used in refrigerated truck bodies, they can also be used in other applications that require insulation, such as winter capsule houses and cold rooms. Insulation panels are required to block the entry of heat from the outside while providing protection. In insulation applications, the thickness is usually 30mm or more to ensure cold storage performance.

In the field of construction, the use of sandwich panels are also very many cases, and the benefits are very, as the first choice for modular buildings, it has high strength, and good insulation, easy to install, low cost, easy to customize, short production cycle and other advantages. It is used for building facades, roofs, and partitions, and has been widely used around the world.

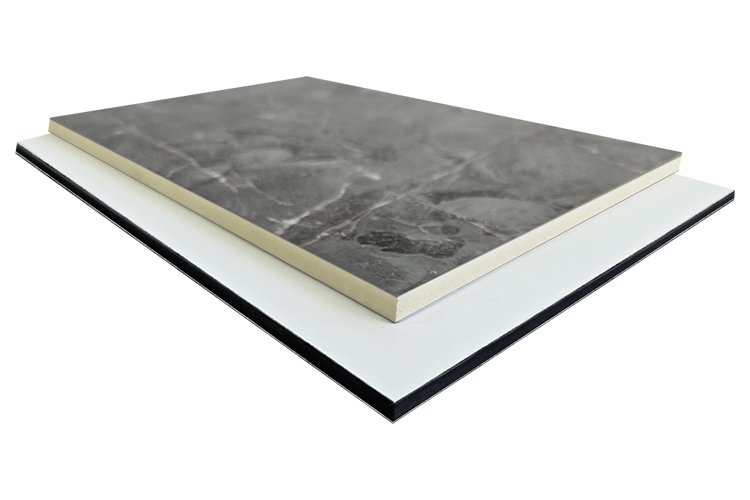

Decorative laminated panels for exterior walls

Exterior sandwich panels can generally be used in buildings, commercial buildings, schools, office buildings, hospitals, and other places. It is used for continuous laying on the exterior with a simple connection. It is usually used as a decoration and to a certain extent can play a role in thermal insulation.

Roof Sandwich Panel

Roof sandwich panels usually have waterproof and moisture-proof performance to prevent leakage and other phenomena, and must cope with a variety of extreme environments.

| Core Material Type | Thermal Conductivity (W/m·K) | Compressive Strength | Representative Applications |

|---|---|---|---|

| PU Polyurethane Foam | 0.023 | 200 – 400kPa | Refrigerated Vehicle Bodies |

| XPS Extruded Polystyrene | 0.027 | 400kPa – level | Freight Box – type Trucks |

| PET Foaming Material | 0.033 | Above 500kPa | High – end RV Floors |

| Polypropylene Honeycomb | – | Transverse Compressive Strength 1.5MPa | Box Trucks, Camping Trailers |

FAQ

What is the life expectancy of sandwich panels?

The life span of sandwich panels is usually around 10 to 30 years.

The life span of a sandwich panel depends on the quality of the raw material and the material used. If FRP is used as the skin, the life span can be up to 30 years without any problem. The premise is that daily maintenance is needed, if used in harsh environments, it will accelerate the aging and damage of the sandwich panel. Therefore, regular inspection and maintenance of the sandwich panel is crucial.

What are the dimensions of the panels?

Composite-box produces sandwich panels up to 12 meters long and 3.6 meters wide.

The thickness is usually 10~150mm.

Related Post

Related Product

Author introduction

Hello, customers

My name is Jack Yu and I am the Business Manager of Composite Box. I have been in the business of sandwich panels, refrigerated trucks and RVs for more than 10 years. Please feel free to contact us. I am happy to provide you with the best service and products.

Email: info@composite-box.com | Tel: 86+17280837525