What Are FRP Panels? A Guide To Features And Applications

Fiberglass reinforced plastic panels (FRP panels) are now common in many industries. Since the invention of high-strength FRP panels in 1960, they have been used in many applications. They are strong, tough, and lightweight. In addition to being used for building interior walls and partitions, they have also been used in refrigeration box trucks, roofs, wall panels, automobiles, trucks, ships, airplanes, and other applications. This article takes you through the benefits of FRP, what it consists of, and how it is manufactured.

What is FRP (Fiberglass Reinforced Plastic) panel?

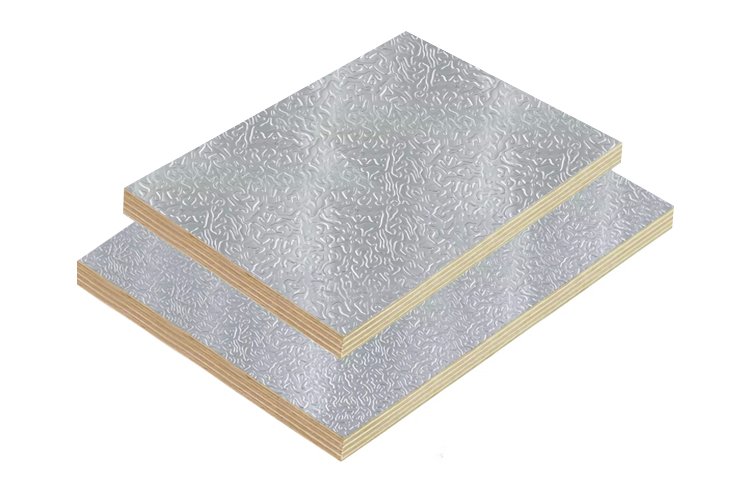

FRP is made from fiberglass and polyester resins and is a high-performance plastic blend. The fiberglass are made of ultra-fine glass with a small diameter and are very thin. For applications requiring enhanced structural support, GRP plywood panels combine the strength of FRP with the rigidity of plywood. It can be less than 1mm thick, has a strong tensile strength, a very strong and resilient surface, and is polished to a very smooth surface.

Fiberglass is waterproof, moisture-proof, fireproof, chemically stable, and has good aesthetic value. It can absorb sound. So, it can be made into fireproof, sound-absorbing fiberglass-reinforced plastic panels.

How are fiberglass reinforced panels manufactured?

Understanding fiberglass-reinforced plastic panels begins with the manufacture of fiberglass sheets.

Powerful fiberglass-reinforced plastic (FRP) panels have excellent performance and strength-to-weight ratios, thanks to the manufacturing process and the raw materials used. Typically, the manufacture of FRP requires the use of ultra-fine fiberglass, usually only 4 to 30 microns (μ) in diameter and liquid resins.

Manufacturing and Processing Flow

The liquid resin acts as a bonding agent, covering the woven fiberglass. It can enhance its strength and toughness. Then, spray polyester and spray epoxy resin layers can increase the volume and thickness, also called the coating process. They add strength and durability.

Finally, they are heated and cured. The result is a fiberglass-reinforced panel. It is a high-strength material used in many industries. It has a beautiful look. It also has high strength and pressure resistance. So, it can be used in various industries.

Fiberglass-reinforced plastic panels are divided into two kinds: continuous filament process and short fiber processes.

Diversity of FRP

In addition to FRP panels, fiberglass can also be used to make fiberglass tape and fiberglass cloth.

Although fiberglass can be made in many forms, in most cases it is only available in white or black.

Comparison between FRP panel and other materials

The biggest rival to FRP panels, and the material most capable of replacing them, is ACP (aluminum composite panels).

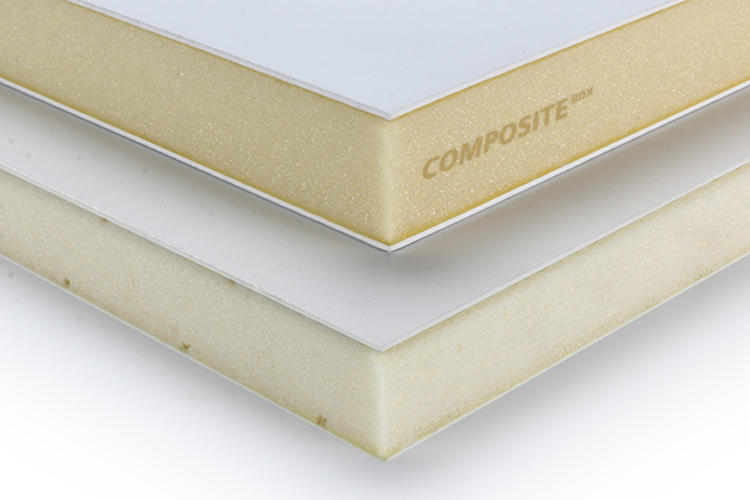

Fiberglass-reinforced plastic is commonly used in the manufacture of fiberglass foam panels and consists of polyester resin and fine fiberglass. It is lighter in weight, stronger in performance, fire-, water-, and moisture-resistant, and has superior performance.

Comparison of FRP and ACP

Aluminum composite panels, or ACP, are chemically fragile and cannot be used with materials such as hydrochloric or sulfuric acid, or with materials containing chlorine or sodium hypochlorite. FRP is able to maintain excellent corrosion resistance in strong alkaline and acidic environments.

FRP panels are used in high-strength applications without fatigue or bending. While aluminum composite panels are strong, they rust and fatigue. Therefore, FRP is a popular high-strength material in the market today.

FRP panels are excellent in terms of thermal conductivity and moisture resistance. Because they have low thermal conductivity, whether in a high-density humidity environment or a high-temperature environment, FRP shows greater stability and is difficult to change due to the environment.

In short, aluminum composite panels are prone to deformation and breakage when exposed to high strength, while FRP is the material that can really provide high performance and safety.

Comparison of FRP with other materials

FRP still has great advantages over carbon fiber, steel, acrylic, etc. Learn more about our carbon fiber honeycomb panels for lightweight, high-strength alternatives. Therefore, FRP foam panels produced by FRP are very popular among the public. If you have problems choosing a material, please contact our experts.

What are the uses of fiberglass?

With properties such as high performance, resistance to bending, light weight, durability, and high thermal barrier properties, fiberglass is one of the most widely preferred materials in the industry and can be used in many industries to enhance their performance and increase the service life. Following is the wide range of uses and applications of fiberglass:

RV Structures:

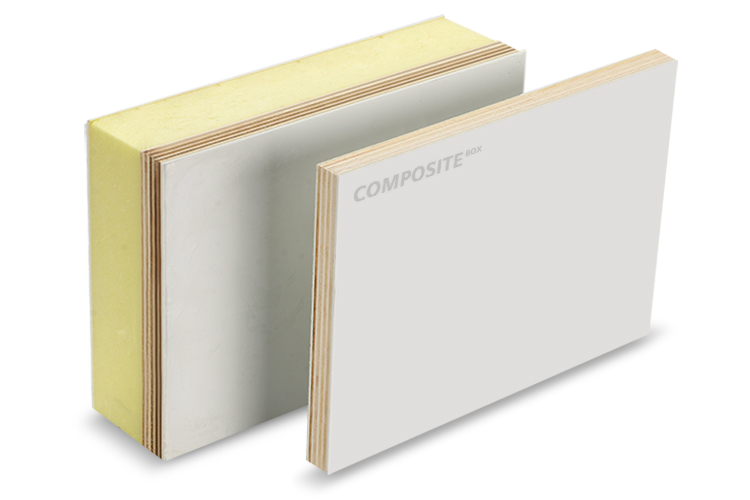

Fiberglass foam panels and fiberglass plywood panel play an important role in RV manufacturing and fiberglass enclosed trailers to improve fuel efficiency and drivability, and they have good durability to protect the internal structure and meet the diversity of RVs.

FRP panels are also ideal for our enclosed car trailer, providing lightweight and durable protection for vehicle transport.

FRP Foam Acoustic Panels:

A new type of material that comes from the use of FRP sheets and foam lamination, which has excellent performance in sound insulation and sound absorption, can reduce noise pollution. Improve people’s comfort in life and work.

FRP foam thermal insulation panel:

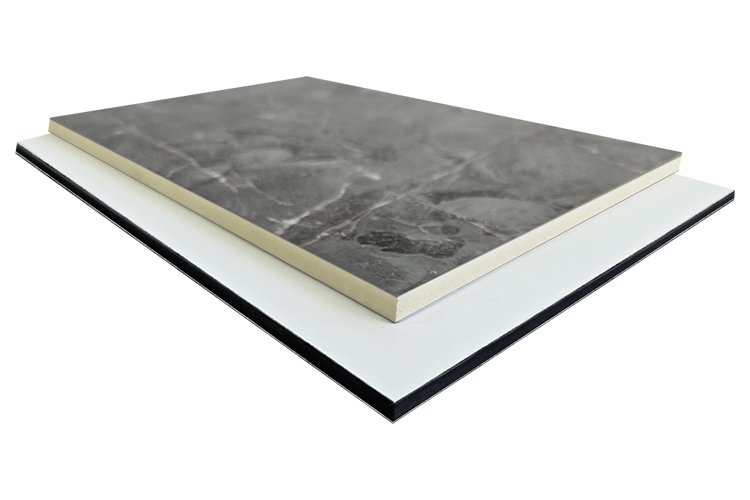

FRP XPS panels and FRP PU panels are the best examples, widely used in cold rooms, refrigerated trucks, which are important components in refrigerated trucks. For a full – scale introduction to refrigerated trucks, check out this guide. and other applications; they can provide excellent thermal insulation performance, can also be used in roofs, walls, and floors, and can reduce energy consumption and keep the temperature from changing due to the outside.

Floors, ceilings, and internal walls:

FRP manufactured sandwich panels can be used for floors, ceilings, and internal walls; FRP is very wear-resistant, non-slip, easy to clean, and has other advantages. It is used in a large number of public buildings, commercial centers, etc., and not only can it provide strong performance, but it can also provide a beautiful and attractive decorative effect.

Exterior Wall Finishes:

FRP is used for exterior wall finishes to provide excellent protection and weather resistance, and with the addition of a UV-resistant coating, it is resistant to ultraviolet radiation. It can be customized on the market in a variety of colors and textures to meet the needs of different styles.

Marine vessels:

It can be used to produce plywood panels, cabins, etc. for ships, which can resist the corrosion of seawater, have excellent resistance to abrasion, and other properties, providing strong structural support and a good living environment.

Fiberglass tape:

Fiberglass can also be used to produce fiberglass tape, which can be used in any field that requires high temperature and corrosion resistance, and can be used to pack, fix, and seal materials that need to be reinforced.

Fiberglass Cloth:

Fiberglass can be used to produce fiberglass cloth, a material made from woven fiberglass yarns that can be used to make products such as fire curtains and heat shields, providing high-performance solutions for a variety of scenarios.

Refrigerated box truck body:

Used in the production of refrigerated trucks, freezers, and other trucks and trailers, it can be perfectly used in a variety of kits, such as doors, side doors, side panels, etc., providing good thermal insulation and heat insulation.

Guardhouse:

FRP can produce strong and lightweight wall panels that can improve safety, making it suitable for use in the production of guard rooms.

What are the features and benefits of fiberglass reinforced panels?

- Scratch Resistant: The fiberglass sheet surface has scratch-resistant properties.

- Lightweight: lightweight, high strength-to-weight ratio.

- Easy to clean: The FRP surface is smooth and does not easily harbor bacteria, dirt, etc.

- Chemical resistance: very resistant; can operate normally in acidic and alkaline environments.

- High strength: FRP is very strong, not easy to deform or break.

- Long service life: FRP has a long service life because it is well tolerated and resistant to decay.

- FRP panels resist corrosion: They suit many modular structures.

- Easy to maintain: easy to clean and maintain.

- Good durability: fiberglass-reinforced panels are very strong. They perform well and can withstand harsh conditions.

- Durable: it has excellent chemical properties and is not affected by the environment.

- Non-conductive: It is an excellent electrical insulator.

- Affordable: it has a strong price advantage when compared to materials such as aluminum and steel.

- Non-rusting: FRP does not rust due to a chemical reaction with oxygen.

- Non-magnetic: Fiberglass is not magnetic.

The Bottom Line

Fiberglass reinforced plastic panels are widely recognized by the industry; it not only has excellent high strength and bending resistance, but is also easy to process and use. It is indispensable for a wide range of industrial, construction, automotive, and aerospace fields. Fiberglass reinforced plastic is the main product of Composite Box Group; we are committed to meeting all your solutions, making your project simpler and more reliable!

Related Post

Related Product

Author introduction

Hello, customers

My name is Jack Yu and I am the Business Manager of Composite Box. I have been in the business of sandwich panels, refrigerated trucks and RVs for more than 10 years. Please feel free to contact us. I am happy to provide you with the best service and products.

Email: info@composite-box.com | Tel: 86+17280837525