Aluminum Box truck Bodies

Aluminum box truck bodies have a metallic appearance and outperform steel van bodies in every aspect. They “excel in durability, are impact resistant, lightweight, and are not prone to corrosion and cracking. It outlasts fiberglass truck bodies and steel bodies by more than 40 years. Creates a versatile truck body. Ensure safety, stability, and innovation.

We offer lightweight bodies, aluminum semi-trailer bodies, flatbed bodies, and curtainsider trucks.

Features

There is a great variety of aluminum box truck bodies on the market, and we are trying to stand out and win the continued trust of more customers. We continue to improve our processes and technology, and our latest aluminum bodies, using modular splicing design, are both stable and conducive to installation and sales.

We have a finished production line for aluminum sandwich panels and a CNC cutting line. We are free to customize the size you need, and we support CKD delivery and can put all parts into one container.

Get Free Quote of Aluminum Box truck Bodies

Customization Options

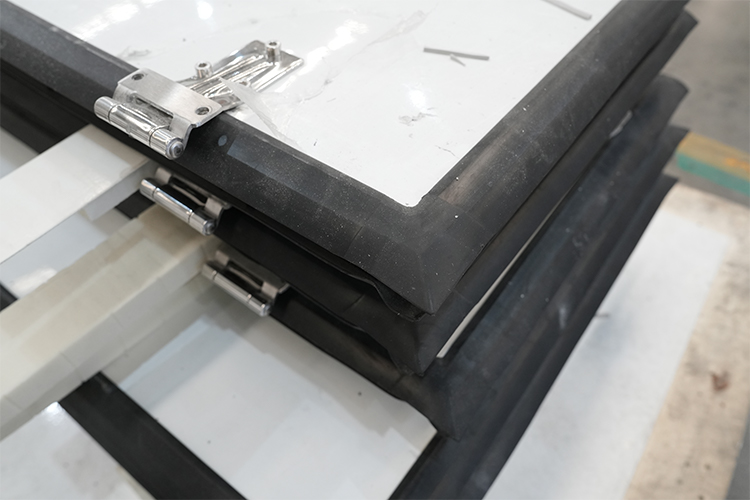

Composite box offers you the most comprehensive range of aluminum box truck bodies and offers customization of sizes, whether it’s 10′ or 20′. We provide designs and offer complete kits, such as LED lights, body chassis and frames, doors, hinges, locks, bumpers, subframes, floors, E-tracks, and more.

Advantage

When you buy an aluminum boxcar body, the most important thing is the diversity of functions, beautiful appearance, and whether the material is strong, and whether it will corrode and break in later use. We have solved all these problems through continuous innovation. By choosing us, you will have the following benefits:

- Exquisite appearance

The aluminum box truck body has a beautiful metallic luster, as well as stainless steel edges, beautiful seams, and doors. - Corrosion resistance

You don’t need to worry about getting hurt on the road, even if you encounter a violent storm, because our products are corrosion-resistant. - Low Cost

Adopting the splicing design can effectively reduce the cost and increase the cost-effectiveness, and the aluminum alloy is very quality-assured. - Multiple Customized Kits

We offer a variety of accessory options, LED lights, and aerodynamic front feet. - Adopt seamless design

Our splicing plate adopts a seamless design, which can provide good sealing performance. - Lightweight

Using an aluminum body reduces weight by more than 50%, which is much lighter than steel and can improve fuel efficiency - High strength:

Aluminum is very strong and can withstand most collisions.

case

6.8 m aluminum truck parameters:

- Used for city distribution of dry goods products, with double side to side doors for easy stopping for loading and unloading.

- External length: 6800mm.

- External height: 2650mm.

- Outside width: 2450mm.

- Inward length: 6750mm.

- Inward width: 2400mm.

- Bottom thickness: 25mm.

- Base plate: aluminum alloy profile.

- Side Doors: Dual side to side, right side is dominant.

- Bare weight (all aluminum): 750kg.

- Door thickness: 25mm.

- Rear door: double opening, 180° opposite.

- Panel height: 2400mm.

- Lock: Stainless steel, anti-theft and anti-rust.

- Volume: 38.4 square meters.

- Load: 10 tons.

Application

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.