Composite Food Truck Solutions

We are suppliers of box bodies for food trucks. We provide side panels, floors, and ceilings. We offer complete trailer chassis. Using fiberglass foam sandwich panels or continuous fiber (CFRT) as the skin. We provide prefabricated modules delivered in CKD/SKD form. We are the premier custom solution provider for mobile food trucks.

Get Free Quote of Composite Food Truck Solutions

Features

Composite Box specializes in manufacturing food trucks. Our structures feature FRP/CFRT skins bonded with various foams (XPS, PU, PVC, and PET), plywood, and PP honeycomb cores. We employ continuous composite molding technology. Core thickness ranges from 30 to 120mm, accommodating all catering requirements. Materials are safe and comply with food hygiene standards. We support surface finishing. Service windows/exhaust vents/light openings are pre-reserved. Customizable beveled edges and aluminum snap-fit channels are available. Suitable for truck chassis or as trailers, with dual-axle and triple-axle trailer production options. As an experienced food truck manufacturer, we provide design services and involve you in our manufacturing process.

Food Truck Panel Specifications

Custom Side and Wall Panels:

Wall panels serve as the fast-food truck’s outer shell. Constructed with FRP inner skin + CFRT outer skin + optional core material. Can accommodate service windows/exhaust vents/lighting openings. Features fire-resistant design compliant with B-s1,d0 fire rating + NSF standards.

Ceiling Customization:

The ceiling features a CFRT skin over a foam core. It accommodates LED lighting and exhaust fans. Built-in cable channels are pre-installed. Edge aluminum channels snap seamlessly into side walls. Thermal insulation K-value: 0.20. Meets fire-resistant design requirements. Designed for lightweight construction.

Flooring:

Flooring utilizes CFRT surface + PP honeycomb core construction. Features anti-slip textured surface. Impact resistance: 18J.

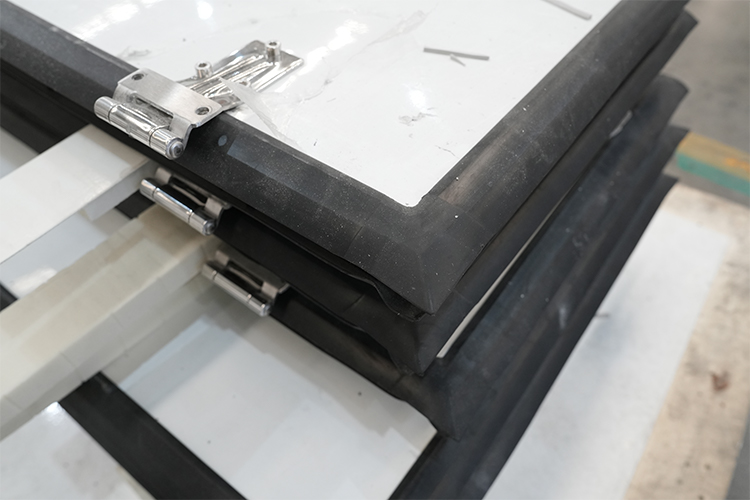

Lightweight Composite Door Modules:

Rear or side doors employ prefabricated modules. Door frames reinforced with aluminum alloy. Triple-seal dust/waterproof gaskets. Smooth opening operation. Can incorporate anti-theft functionality. Impact-resistant.

Fast Delivery for Your Food Truck

We are a leading food truck manufacturer. Our CKD design allows your food truck to be assembled quickly at its destination, like building with blocks. CKD shipment as fast as 7 days, with assembly completed in 14 days. Here is our delivery process:

- 1. Confirm requirements and details

- 2. Finalize design and specifications

- 3. Factory pre-assembly and testing

- 4. Mass production

- 5. CKD shipment

Compared to traditional aluminum-bodied food trucks

| 4.2m | 580kg | 230kg | 350kg | 8% |

| 6.0m | 820kg | 380kg | 440kg | 10% |

| 9.6m | 1200kg | 700kg | 500kg | 12% |

Customization options

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.