fiberglass foam sandwich Panels manufacturer in china

About fiberglass composite sandwich panels

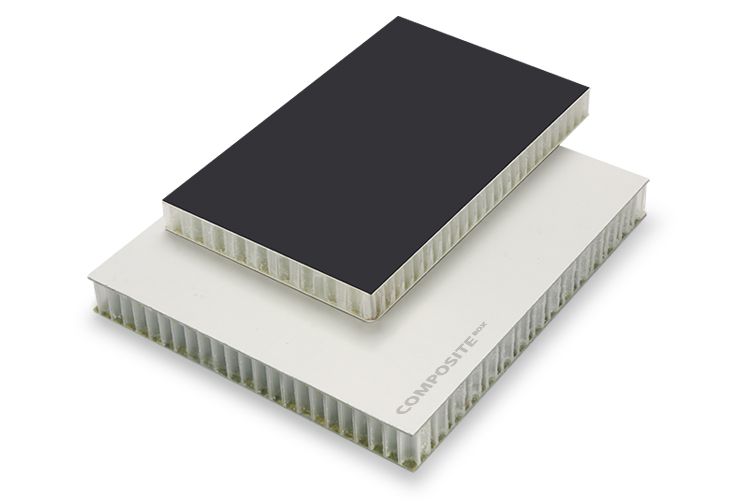

Fiberglass sandwich panels have many excellent properties. The skin uses fiberglass reinforced sheets, or FRP composite panels, and their flat surface and high strength allow for use in a variety of industry applications. Manufacturers create FRP using glass fiber and resin through processes such as hand lay-up, spray-up, and thermo compression molding. The core is made of plastic foam, GRP coated plywood, and PP honeycomb panels, which can be selected from XPS, PU, PVC, PET, plywood, and PP honeycomb. They have different advantages and properties, Explore our carbon fiber honeycomb panels for superior strength and lightweight benefits. It is an impact resistance and high-strength material. There are many differences in lightness, insulation, density, life, and cost.

The FRP sandwich panels are cured by vacuum and high pressure. They are bonded with high-quality adhesives. Use of gel coat. Suitable for use in high-strength, corrosion-resistant applications such as building wall panels, dry trucks, reefer, and marine applications. You can also achieve it with FRP on top and CFRT skin underneath.

We are excellent FRP sandwich panel manufacturers; we provide you with the best products. We provide OEM/ODM services such as material selection, CAD and 3D drawing, machining methods, machining process, testing, and CNC machining. If you need, please feel free to contact our experts.

advantages:

Related Product:

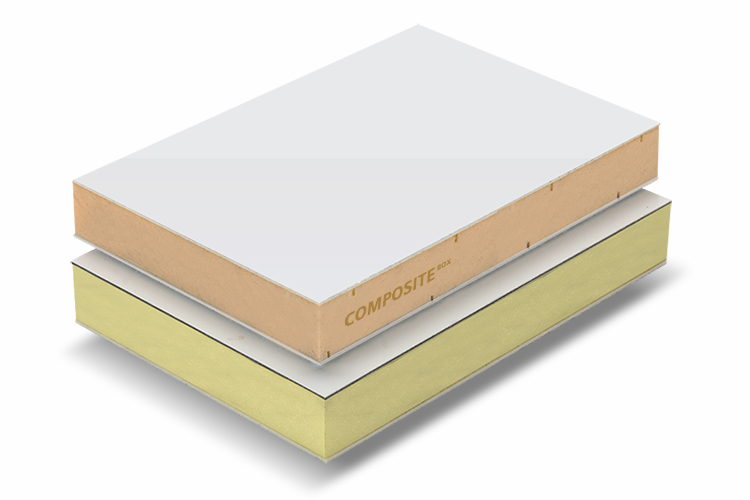

Fiberglass XPS Foam sandwich Panel

Characteristics: Using the vacuum laminating process, FRP XPS foam sandwich panels have excellent thermal insulation properties, high compressive strength, and are suitable for use in humid and low-temperature environments.

Application: Widely used in construction, refrigerated truck bodies, cold storage, and other environments that require thermal insulation.

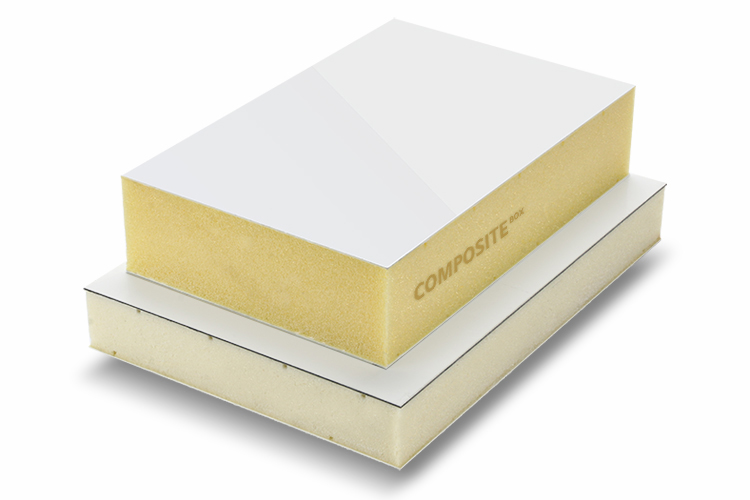

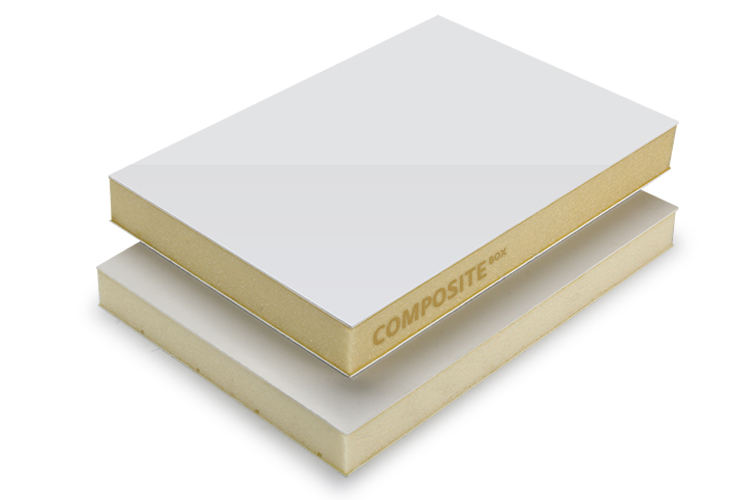

Fiberglass PU Foam Sandwich Panel

Characteristics: Excellent thermal insulation and heat preservation, low thermal conductivity, and lightweight.

Application: It can be used for refrigerated lorry bodies and refrigerated trailer usage.

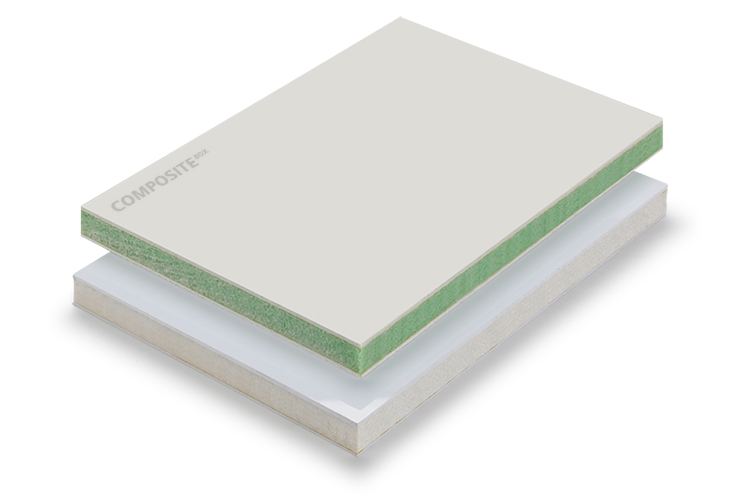

Fiberglass PET foam sandwich panel

Characteristics: has excellent resistance to compression and has a high resistance to pressure

Applications: marine and yacht plywood, building wall panels.

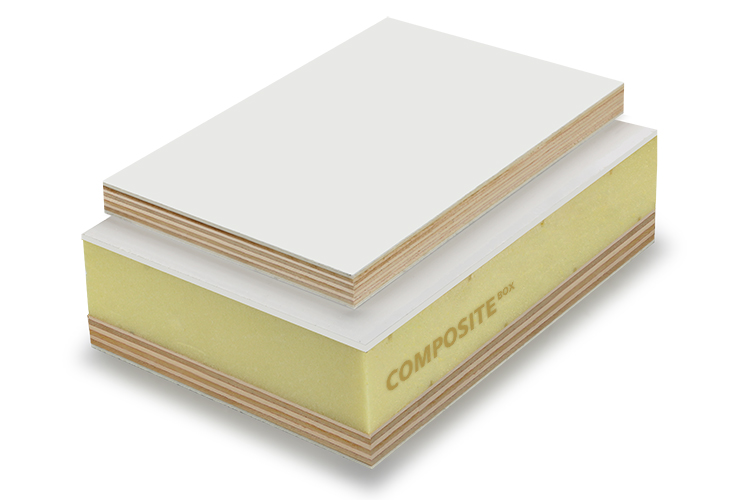

Fiberglass plywood sandwich panel

Characteristics: FRP plywood has high rigidity and very high compressive resistance.

Application: Widely used for floors, walls, ceilings, etc.

product Catalog

contact us

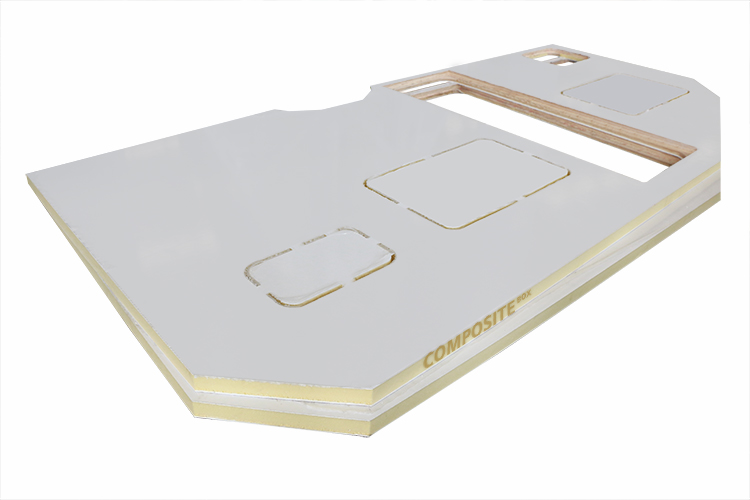

Customized Processing Services

We offer a wide range of OEM and ODM processing customized services:

- Size customization: can produce greatest length ≤ 12 meters, width ≤ 3.2 meters

- Surface treatment: glossy, matte

- Color treatment can be customized according to RAL color.

- CNC processing: precise cutting, punching, and engraving

- Embedded reinforcement: embedded reinforcement materials are available, such as reinforced steel, aluminum, solid wood, fiberglass, or stainless steel plywood for enhanced durability.

- Surface treatment: UV-resistant coating, plastic protective film.

Composite Box

Application of FRP Foam sandwich panels :

- Truck: Can be used for dry lorry, frozen, refrigerated lorry body, and fiberglass cargo trailers. Used for transporting fresh marshmallows, meat, cold drinks, etc.

- Construction: Can be used for house flooring, wall paneling, ceilings, partition walls. Mobile home, mobile toilets, etc.

- Transport: It can be used for wall panels, floors, and partitions of ships and yachts. Train and bus floors, ceilings, etc.

- Sporting goods: can produce table tennis tables, ping pong rackets, etc.

- Caravan: Wall panels, floors, and partitions for caravan bodies, caravans, etc.

- Aviation can be used for cabin interior panels and wall panels.

- Other applications: cold storage, interior insulation panels, exterior cladding, storefront decoration, etc.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.