XPS core Sandwich panels manufacturer in china

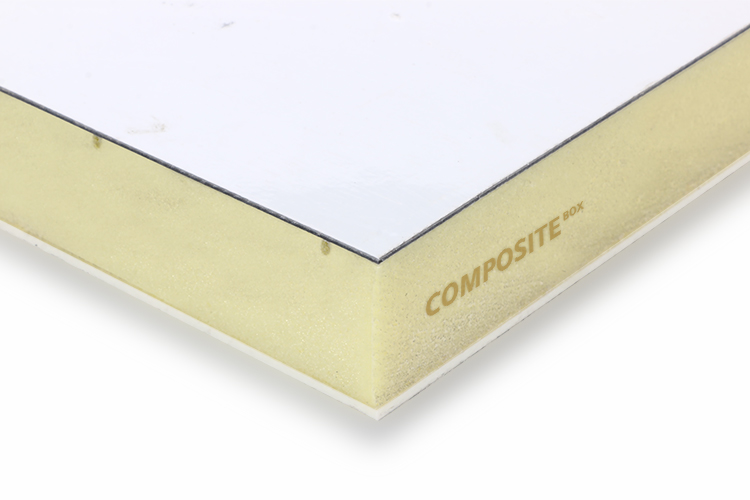

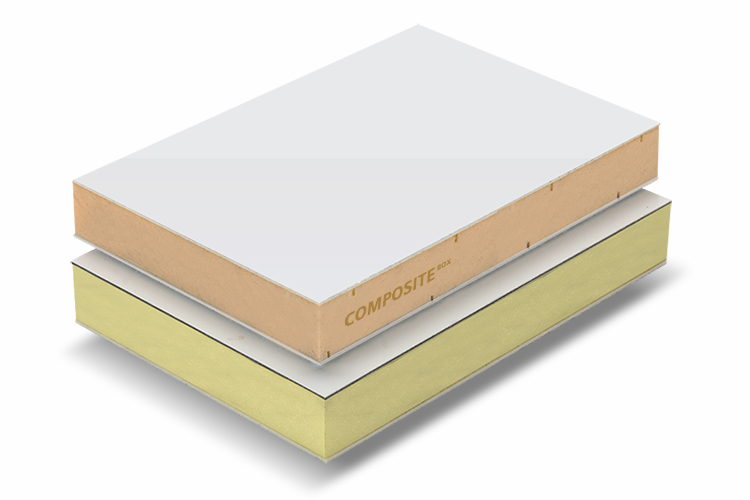

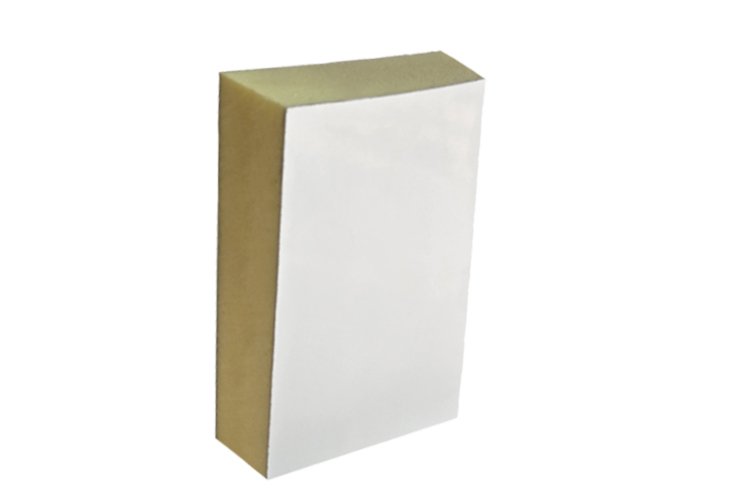

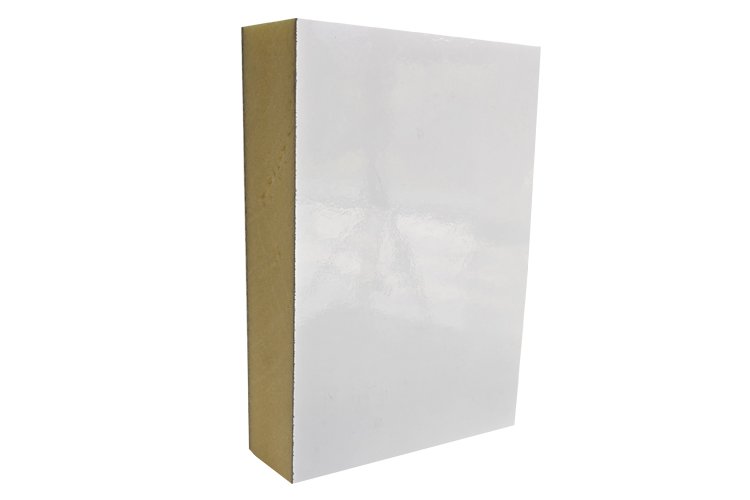

XPS foam sandwich panels are popular insulation materials called ‘XPS insulation boards’. Good thermal and acoustic insulation is frequently used in refrigerated trucks and RVs. It has an XPS (closed cell extruded polystyrene) core. The outside is bonded with FRP, plywood, or CFRT. The XPS foam is a great thermal insulator. It does not absorb water, so it has a long service life. The skin makes XPS panels perform better. The FRP skin can replace traditional materials, like aluminum and steel, to make them stronger. It’s the best choice for refrigerated trucks and RV panels.

We are the most professional XPS sandwich panel manufacturer in China. We offer OEM production with customized sizes and skins, CNC machining services.

Features

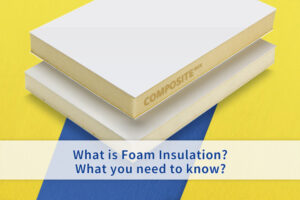

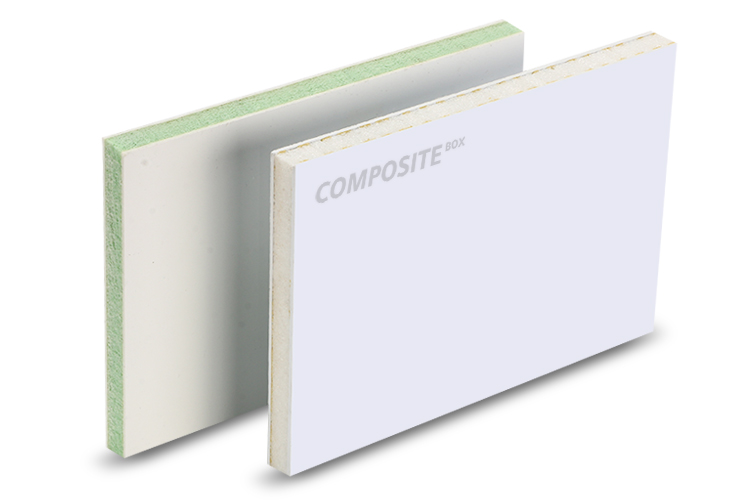

Structure: FRP sheet for the skin, PET foam core for the core.

Composite-box manufacturer has been specializing in the production of fiberglass PET foam panels for 20 years. PET is a recyclable and environmentally friendly foam core. Interestingly, the recycled PET foam core is green in color. Our diverse range of products is sure to be ideal for you.

Our products are bonded using environmentally friendly adhesives and laminated using vacuum and high-pressure equipment. This ensures that they will not crack and de-glue during use. If you need to use them for special applications or high-strength scenarios, they can be embedded with reinforced steel, FRP, aluminum profiles, plywood, etc. to be more robust. Our products have a long service life, and the exterior treatment uses a film that protects the FRP skin, and the exterior can also be added with flame retardant and anti-UV agents to improve durability. The working temperature can reach -40℃ to 130℃.

Get Free Quote of XPS Core Sandwich panels

Product Description

XPS sandwich panels are high-performance and very durable, and they offer many advantages. The best advantage is its excellent thermal and sound insulation.

- Good thermal insulation and heat preservation performance.

- High strength: bonded skin to form a high-strength sandwich panel

- Durable: not easy to corrode or age

- Strong: not easy to deform and compress

- Insulation prevents air from entering and exiting.

- Non-absorbent: a closed-cell structure prevents water absorption.

- Chemically stable and designed for a long service life.

customization

- Surface skin: FRP skin, CFRT, aluminium sheet, plywood, etc.

- Size: length ≤12m, width ≤3.2m, thickness: 20mm~120mm.

- Density: 25~45kg/m³

- Colour customization: yellow, green, blue.

- Skin colour: according to the type of masking

- Compressive strength: tuning density and proportion of foaming agent

Product Structure

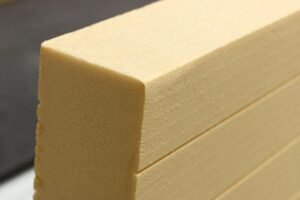

XPS foam board

XPS foam board is also called extruded polystyrene board, it is a kind of rigid closed-cell foam, which has obvious difference with expanded polystyrene, it has less than 1% moisture absorption. Low thermal conductivity. Good impact resistance.

Fiberglass Reinforced Plate

Fiberglass reinforced plate is made by combining glass fibers and resin matrix. It is suitable for the manufacture of fiberglass XPS foam board, which is a high-performance composite material.

Product Structure

| Parameter | Description |

| Density | 33-50 kg/m³ |

| Compressive Strength | 500-700 kPa |

| Thermal Conductivity | 0.028-0.035 W/(m·K) |

| R-Value | ~5 per inch |

| Water Absorption | <1% (closed-cell structure) |

| Fire Rating | B1/B2 (China standard) |

| Operating Temperature | -50°C to 75°C |

application

Related Product

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.