Sliding Side Door Box Truck Body

The sliding side door box truck bodies features a modular design. High-strength FRP (fiberglass reinforced plastic) serves as the outer skin, while the interior utilizes high-strength rigid XPS/PET foam to form composite panels. This achieves lightweight construction and exceptional thermal insulation. At its core is a rapidly assembled sliding side door system, supporting flexible customization of dimensions and functionality. Door assemblies can be supplied separately to meet diverse transportation and modification requirements. Delivered in CKD and SKD configurations.

Features

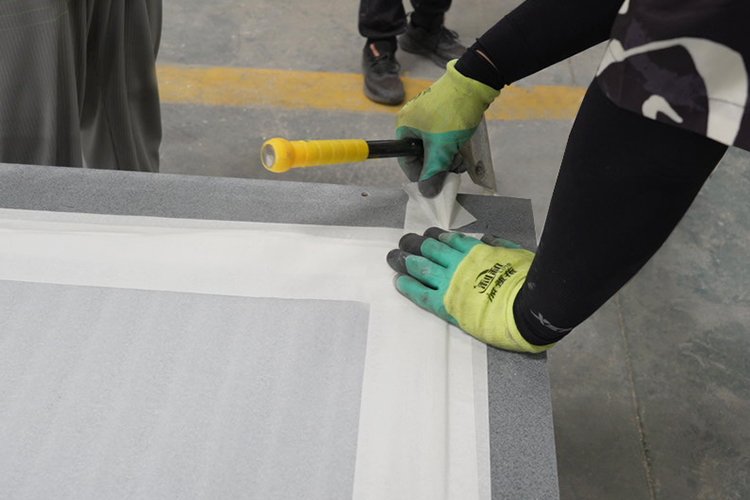

This sliding side door box truck body employs advanced composite materials and modular design. The structure consists of high-strength FRP (fiberglass reinforced plastic) as the inner and outer skins, with a tightly bonded high-density XPS (extruded polystyrene) or eco-friendly PET foam insulation core sandwiched between them, forming a sandwich panel through advanced composite processes. This construction ensures overall structural strength and rigidity while delivering exceptional lightweight properties and thermal insulation, making it particularly suitable for temperature-sensitive cargo or high-efficiency payload transportation scenarios.

The sliding side door system features a well-engineered design with smooth-running tracks, enabling effortless large-opening access for rapid forklift or manual loading/unloading of diverse cargo. We offer highly flexible customization services, allowing clients to tailor the body’s internal/external dimensions, panel thickness, door locations, and quantities based on specific cargo requirements (e.g., equipment size, insulation needs). We supply both standalone sliding door and track assemblies for retrofitting existing vehicles, as well as complete body kits encompassing panels, frames, and full hardware sets for turnkey delivery. This comprehensive offering addresses diverse needs from urban distribution to specialized logistics.

Get Free Quote of Sliding Side Door Box Truck Body

Body Structure

| Part Name | Main Components |

|---|---|

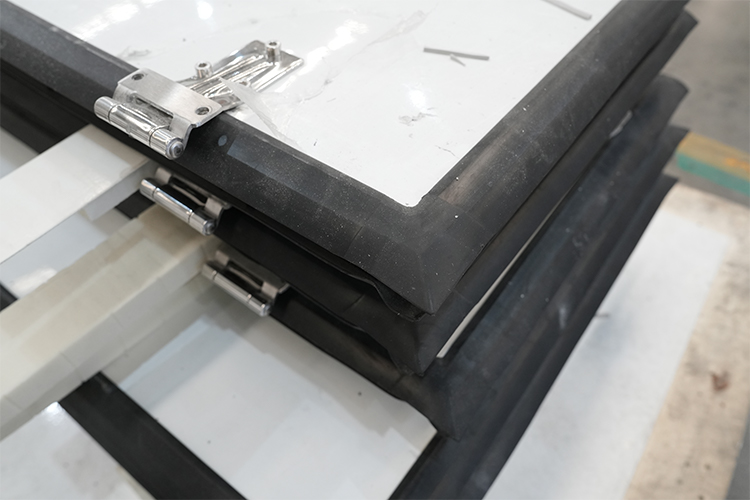

| Main Body / Cargo Box | FRP outer skin, XPS/PET foam core, FRP inner skin (composite panel), Aluminum alloy or steel frame, Sealing gasket |

| Sliding Side Door System | Sliding door panel (composite panel), Upper/lower track, Roller assembly, Door lock mechanism (bolt lock / paddle lock), Bumper block, Sealing gasket |

| Front Wall & Roof | Front wall composite panel, Roof composite panel, Waterproof seal, Spoiler / fairing (optional) |

| Rear Door System | Swing doors or roller shutter door, Door frame, Hinges, Locks, Sealing gasket |

| Floor Structure | Floor plate (anti-slip aluminum plate or multi-layer composite board), Cross members, Protective guard / underrun bar |

| Accessories & Hardware | Interior/Exterior lights, Ventilation window, Anti-theft device, Fastening bolts, Mounting brackets |

Why Choose Sliding Side Door Cargo Bodies?

- Revolutionary improvement in loading/unloading efficiency: Wide sliding side doors enable full access to the cargo area, facilitating simultaneous forklift operations and reducing loading/unloading time by over 50% compared to traditional double doors.

- Optimal space utilization and maneuverability: Sliding side doors open without occupying external space, allowing effortless operation in narrow aisles or platforms and significantly enhancing environmental adaptability.

- Lower overall operating costs: The lightweight composite body increases payload capacity; superior insulation reduces temperature control energy consumption; durable materials decrease maintenance frequency, delivering significant long-term economic benefits.

- Exceptional Strength and Durability: FRP material resists corrosion and rust, while XPS/PET foam repels water and resists aging. The overall structure boasts strong weather resistance, with a service life far exceeding that of conventional steel bodies.

- High Customization Flexibility and Versatility: Offers multi-form products ranging from components to complete vehicles, supporting comprehensive customization in dimensions, functions, and configurations. Suitable for both new vehicle manufacturing and seamless retrofitting of existing fleets.

Common Parameters and Customization Options

| Parameter | Specifications |

|---|---|

| Cargo Box Dimensions | Length: 4.2 m – 9.6 m Width: 2.2 m – 2.5 m Height: 2.0 m – 2.8 m (Can be adapted to the chassis configuration) |

| Panel Thickness | 40 mm – 80 mm *(Common specifications: 50 mm / 60 mm)* |

| Side Door Width | Single sliding door width can exceed 2.0 m |

| Rated Load Capacity | Varies depending on design and chassis configuration. |

Application

Primarily used in sectors with high demands for loading/unloading efficiency, cargo protection, and space utilization.

- Suitable for urban logistics distribution

- Suitable for cold chain distribution

- Suitable for fresh food transportation

- Transportation of precision instruments

- Mobile retail vehicles

- Emergency command vehicles

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.