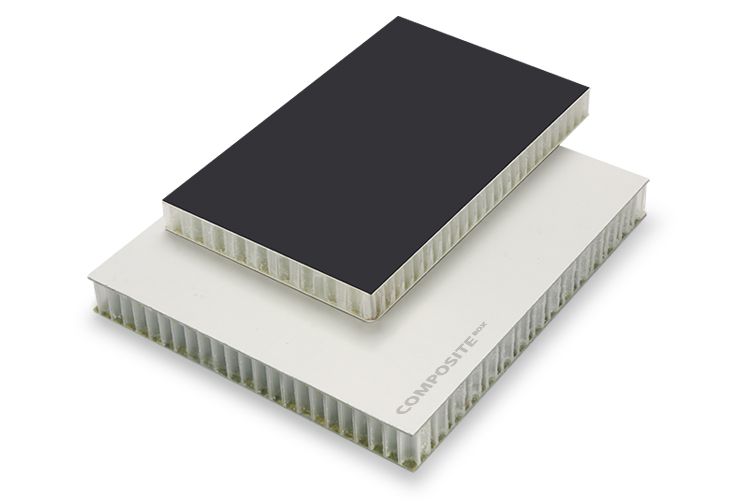

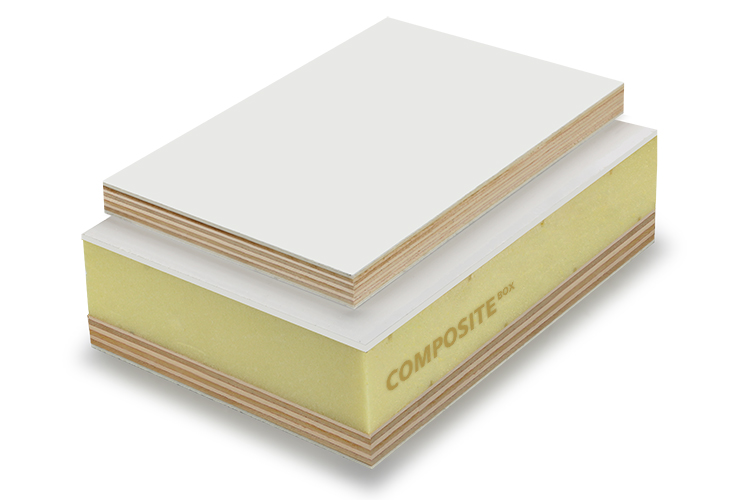

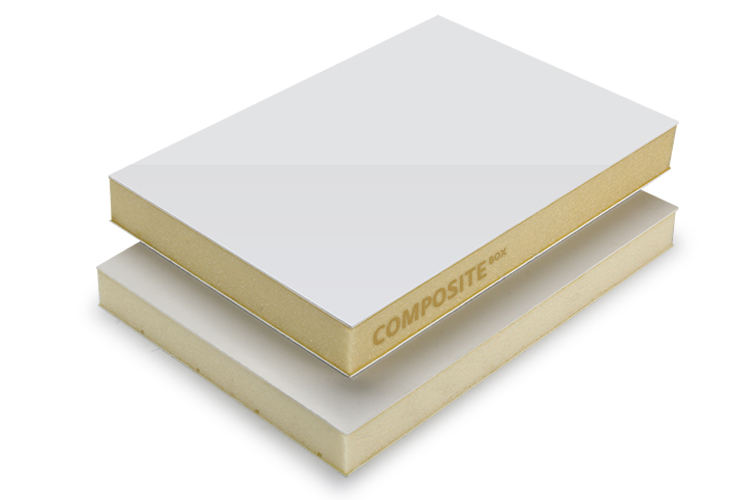

Rigid Foam Board

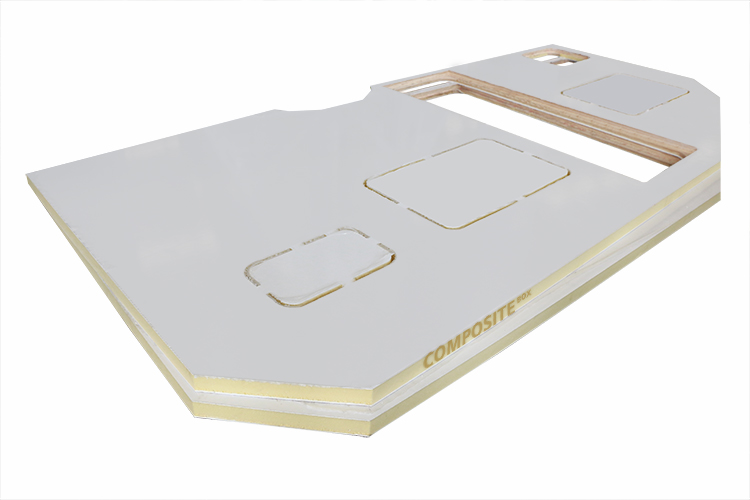

Composite Box provides high-quality rigid foam boards. For example, XPS, polyurethane, PET, and PVC foam. They can be used for truck bodies, construction, and motor homes. They are used for structural, thermal insulation, and waterproofing applications.

We offer custom processing in various sizes and densities, providing a one-stop solution. For inquiries, please contact our sales manager.

Features:

- Thickness range: 5mm to 300mm

- Insulation performance with R-values from 4 to 22

- High-strength structural filling

- Density: 300–800 kg/m³

product

XPS foam board

Description:

XPS foam board is a closed-cell rigid foam with excellent waterproof properties. It uses an extruded polystyrene structure. It has good thermal insulation properties and extremely low water absorption, making it suitable for a wide range of applications.

- Closed cell content exceeds 99%.

- Thermal conductivity: 0.027 W/mK

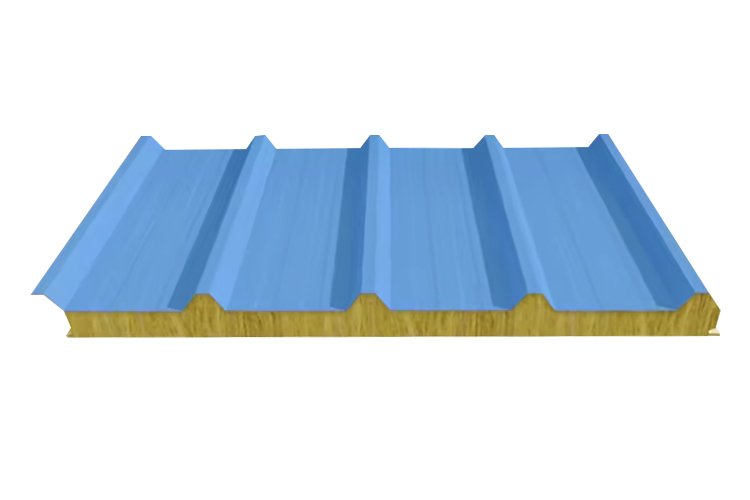

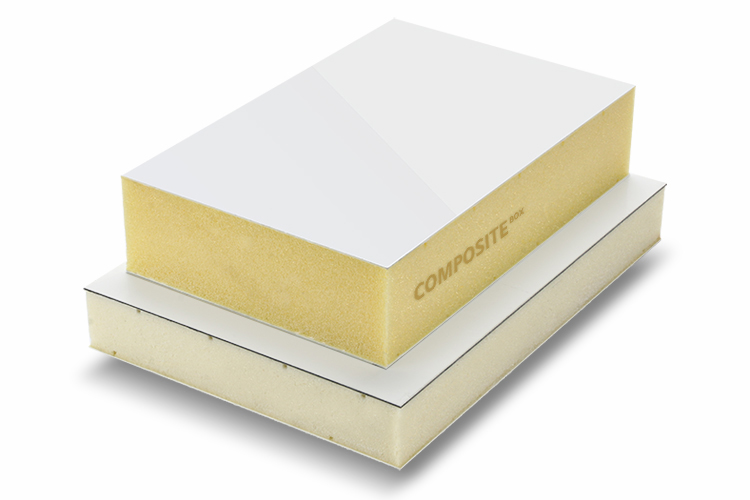

PU Insulation Foam Board

Description:

Polyurethane (PU) foam boards offer exceptional thermal insulation properties. They also feature excellent flame resistance and heat resistance. These boards are ideal for applications such as refrigerated vehicles and insulated buildings.

- Thermal conductivity: 0.023 W/m·K

- Durable and long-lasting

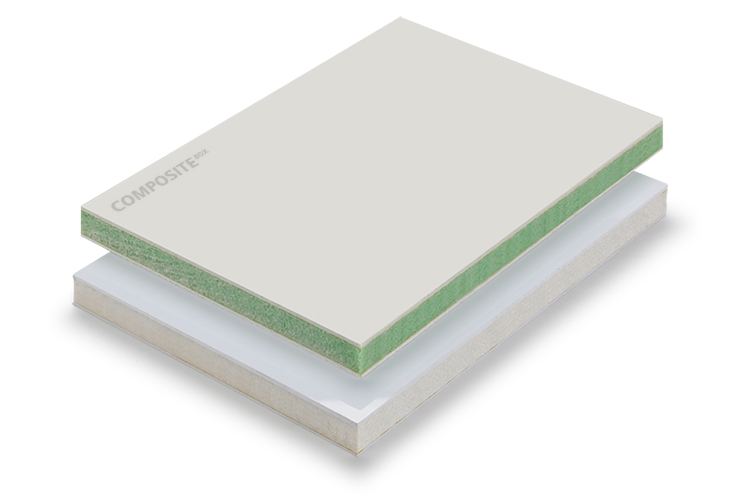

PET foam core material

Description:

Rigid PET foam boards are made from polyethylene terephthalate (PET). They are recyclable foam materials. These boards are heat-resistant and have excellent mechanical properties, making them an outstanding choice for foam board applications.

- Water absorption rate: ≤2%

- Density: 40–300 kg/m³

- Compressive strength: 1.5–2.5 MPa

PMI foam core material

Description:

Composite Box is a professional manufacturer of high-performance PMI foam core and sandwich panels for aerospace, marine, transportation, and wind energy applications.

- Strength-to-weight ratio: 30-50% higher

- Heat resistance: >180°C

- Density range: 30-300kg/m³

Durability

Long service life

Sturdiness

Get Free Quote of Rigid Foam Board

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.