PVC core sandwich panels manufacturer in china

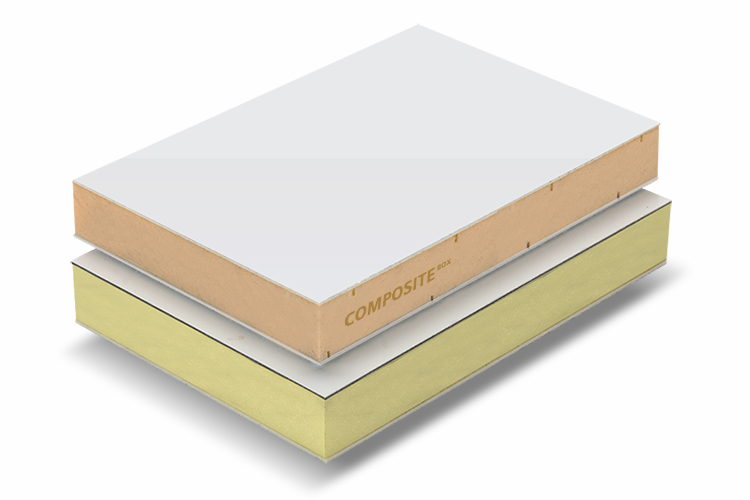

The PVC sandwich panel is made of PVC (polyvinyl chloride) as the core. The skin is made of FRP, CFRT, plywood, and so on. Laminating the core and skin can achieve different functions and properties. PVC foam sandwich is a rigid, closed-cell foam. It is a multifunctional composite material. It is excellent in waterproofing and moisture-proofing, good sound insulation, and so on.

PVC sandwich panel is the best material for wall panels, partitions, and roof. Can meet residential, commercial, restaurant, and other applications.

We provide you with the best sandwich panels and offer OEM customized production. We can create any finish for you instead of traditional wood, steel plate, marble, tile, etc.

Features

Our PVC sandwich panels have strong properties; they are not only a high-strength material but also excellent in thermal and acoustic insulation. It is a widely used composite material.

- Waterproof: closed-cell foam that insulates against external moisture.

- Lightweight: density as low as 45.00 kg/m³.

- Sound insulation: PVC sandwich panels are good sound insulation panels.

- Thermal insulation: low thermal conductivity of 0.041 W/K

- Corrosion resistance: PVC has a stable chemical structure and can be used in wet environments.

- Flame retardant: flame retardant effect to protect safety.

- Easy to clean: easy to clean, not easy to accumulate dust.

For further information, please establish contact with our experts and ask for samples.

Get Free Quote of PVC core sandwich panels

customized

We offer a wide range of customization options for our PVC sandwich panels. To meet the needs of various industries.

Size: length ≤ 12 m, width ≤ 3.6 m, thickness 10–140 mm.

Skin: FRP, CFRT, plywood, aluminum, steel sheet.

Coating: Anti-slip, anti-UV, and flame-retardant added.

Core color: black, white, yellow, green, etc.

Density: 45.00 kg/m³

Application of PVC sandwich panel

PVC sandwich panels are very versatile. They are used in commercial, residential, lorry compartments, and decorative applications.

parameters

| Parameter | Specification |

|---|---|

| Product Name | PVC Sandwich Panel |

| Width | ≤ 3.2 m |

| Thickness | 10–140 mm |

| Length | ≤ 12 m |

| Core Density | 45–250 kg/m³ |

| Thermal Conductivity | 0.041 W/m·K |

| Skin | FRP (Fiberglass Reinforced Plastic), CFRT sheet, plywood, aluminum sheet, steel sheet, etc. |

| Core Color | White, black, green, yellow, etc. |

| Composite Method | Adhesive |

| Surface Finish | Glossy, matte, embossed, etc. |

| Surface Color | RAL colors |

| Core Material | PVC (Polyvinyl Chloride) foam, closed-cell structure, density range: 45–250 kg/m³ |

| Coating Options | Anti-slip, anti-UV, flame retardant |

Custom Processing

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

FAQ

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.