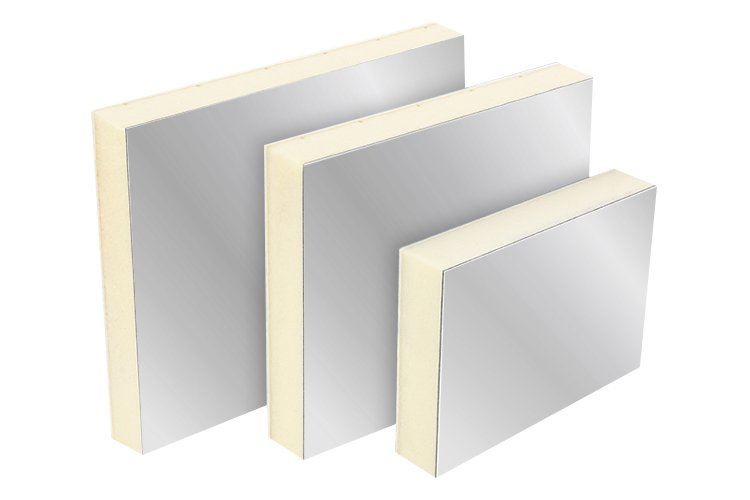

What’s polyurethane sandwich panels?

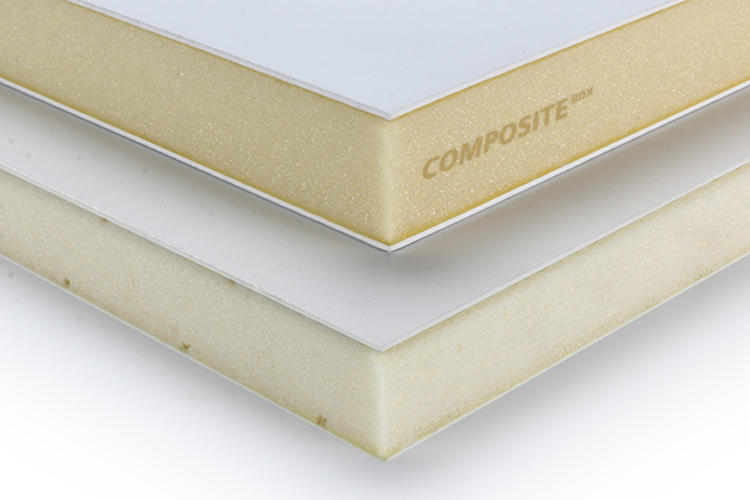

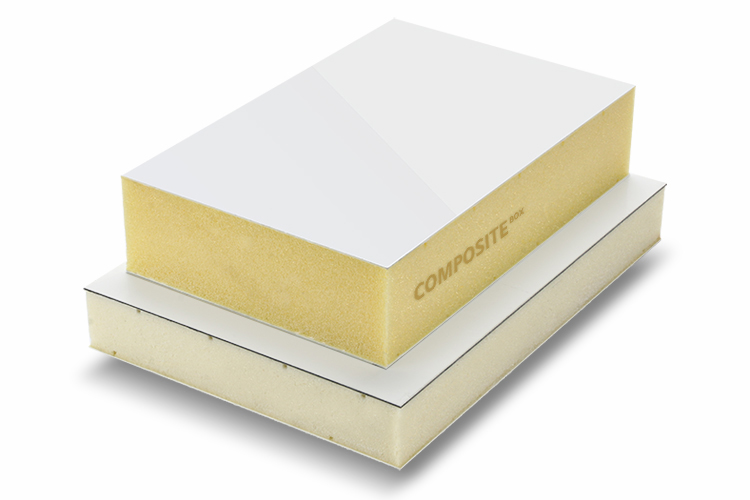

Polyurethane Foam Sandwich Panel is a specialized material for cold storage insulation and thermal insulation. It is made of rigid closed-cell foam PU (polyurethane) as the core, and the outer skin material is FRP (fiberglass), CFRT, and other skins as the skin, which is laminated by vacuum and high pressure. It usually has a three-layer structure or more. It is a thermal insulation, lightweight, heat insulation, fireproof, and weatherproof material, usually used in reefer body, industrial, residential insulation, and other applications. The thermal stability of PU foam is generally -40℃ to 80℃.

We are manufacturers of polyurethane foam sandwich panels; we use high-quality adhesive to make the skin and core more tightly, preventing de-gluing or bulging. We can provide different sizes, colors, finishes, CNC machining, and so on.

Features

feature:

Good thermal insulation: the thermal conductivity of PU foam board ranges from 0.020 to 0.025 W/m-K.

Good compression resistance: low-density compression resistance can be 150-500 kPa and high-density up to 600-1000 kPa.

Good durability: acid-resistant, alkali-resistant, aging-resistant, and waterproof.

UV resistance: UV-resistant treatment improves UV weather resistance.

Easy to install: modular production, easy to install, reduces cost.

Lightweight material: 30-50 kg/m³; reduce weight.

Easy processing: can be easily cut and molded, versatile.

customization:

PU foam core can be deeply customized to ensure high compatibility with any industry and application.

Size: Fully customized sizes, length ≤ 12 m, width ≤ 12 m, thickness ≤ 12 m

Density: 30-50 kg/m³, according to the required insulation and strength requirements.

skin/sheet: FRP, GRP, CFRT sheet, galvanized steel, aluminum, color-coated steel, stainless steel, plywood, etc. can be selected.

Inserts: Inserts can be added to make the structure stronger by incorporating glass fiber, steel tubes, aluminum tubes, etc.

CNC machining: CNC cutting and dicing, etc.

Get Free Quote of PU Sandwich Panels

Application of PU sandwich panels

customization

- Surface skin: FRP skin, CFRT, aluminium sheet, plywood, etc.

- Size: length ≤12m, width ≤3.2m, thickness: 20mm~120mm.

- Density: 25~45kg/m³

- Colour customization: yellow, green, blue.

- Skin colour: according to the type of masking

- Compressive strength: tuning density and proportion of foaming agent

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.