PMI foam Core & Sandwich Manufacturer

Polymethyl methacrylamide (PMI) foam is a high-performance closed-cell rigid foam core material copolymerized from methyl acrylate and methacrylonitrile. It exhibits outstanding specific strength, high-temperature resistance, and fatigue resistance, making it widely used in composite sandwich panels for aerospace, marine, rail transportation, and wind turbine blades. Composite Box offers densities ranging from 30 to 300 kg/m³.

Product Description

Polymethyl methacrylamide (PMI) foam is a comprehensive high-performance foam core material. With a density range of 30-300 kg/m³, it exhibits excellent tensile and compressive strength, particularly maintaining high mechanical property retention at elevated temperatures.

- Compared to PVC and PET foams, PMI exhibits 30-50% higher strength at equivalent densities and significantly superior heat resistance, withstanding curing temperatures exceeding 180°C in prepreg processes.

- Unlike honeycomb materials, PMI foam is isotropic, facilitating curved surface molding without moisture ingress concerns.

It exhibits balanced shear modulus and compressive strength, delivering outstanding fatigue resistance for sustained dynamic loading. PMI foam also features excellent chemical resistance, low moisture absorption, superior dimensional stability, and a high heat deflection temperature exceeding 200°C.

Get Free Quote of PMI foam Core

Related Products

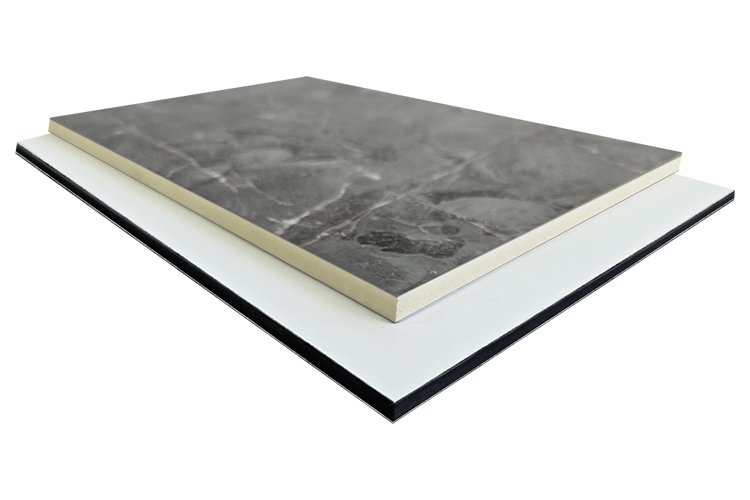

Fiberglass PMI Sandwich Panel

- Features: Lightweight, cost-effective, high impact resistance, strong corrosion resistance, simple forming process

- Applications: Widely used in ship decks, vehicle interiors, radar domes, sports equipment, and building curtain walls. Particularly suitable for curved structural components with medium load requirements, offering excellent cost-performance and durability.

Carbon Fiber/PMI Sandwich Panel

- Features: Exceptionally high specific strength, outstanding rigidity, superior fatigue performance, excellent dimensional stability

- Applications: Primarily used in aerospace structural components (e.g., wings, rudders), high-performance racing parts, premium sports equipment, and high-precision instrumentation, meeting the most demanding lightweight and strength requirements.

Fiberglass PMI Sandwich Panel

- Features: Superior impact resistance, effective electromagnetic shielding, high stiffness-to-weight ratio, strong environmental resistance

- Applications: Suitable for military vehicle armor, aircraft flooring, electromagnetic shielding compartments, high-speed train interiors, and specialized containers, combining structural strength with specialized functional requirements.

Dimensions

| Size (mm) | Color | Density (kg/m³) |

|---|---|---|

| 1000×500 | White | 52 |

| 1250×650 | Beige | 75 |

| 2000×1000 | Light Gray | 110 |

| 1500×750 | White | 150 |

| 2500×1250 | Gray | 200 |

Performance

| Performance Property | Test Standard | Typical Value (Density 75 kg/m³) | Unit |

|---|---|---|---|

| Compressive Strength | ASTM D1621 | 2.1 | MPa |

| Tensile Strength | ASTM D1623 | 3.2 | MPa |

| Shear Strength | ASTM C273 | 1.8 | MPa |

| Flexural Strength | ASTM C393 | 3.5 | MPa |

| Elastic Modulus | ASTM D1621 | 95 | MPa |

| Heat Deflection Temperature | ASTM D648 | 200 | °C |

| Water Absorption (24h) | ASTM D2842 | <0.5 | % |

Product Parameters:

| Property | Value |

|---|---|

| Name | Polyethylene Terephthalate (PET) Rigid Foam |

| Density | 38–200 kg/m³ |

| Thickness | 10–130 mm |

| Thermal Conductivity | 0.03 W/m·K |

| Compressive Strength | 1.5–2.5 MPa |

| Flexural Strength | 10–15 MPa |

| Water Absorbency | ≤2% |

| Recyclability | 100% Recyclable |

| Useful Life | 20 Years |

Generate 4 primary applications

Aerospace: Lightweight structural components such as wings, rudders, radomes, and interior panels

Rail Transportation: High-speed train interior panels, roofs, floors, and sound/heat insulation components

Wind Power Generation: Core reinforcement materials for wind turbine blades to enhance stiffness and fatigue life

Marine Industry: Hulls, decks, and superstructures for luxury yachts and high-speed vessels

Storage Conditions and Precautions

1. Environmental Requirements: Store in a dry, well-ventilated area with relative humidity <70% and temperature between 15-25°C.

2. Avoid Contact: Keep away from organic solvents, strong acids, strong alkalis, and other chemicals to prevent surface corrosion.

3. Protective Measures: Prevent crushing by heavy objects and avoid scratches from sharp items.

4. Stacking Restrictions: Stack flat with a maximum height of 1.5 meters to prevent bottom deformation.

Custom Processing

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

FAQ

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.