Polypropylene PP Honeycomb Panels manufacturer in china

About Polypropylene PP Honeycomb Panels

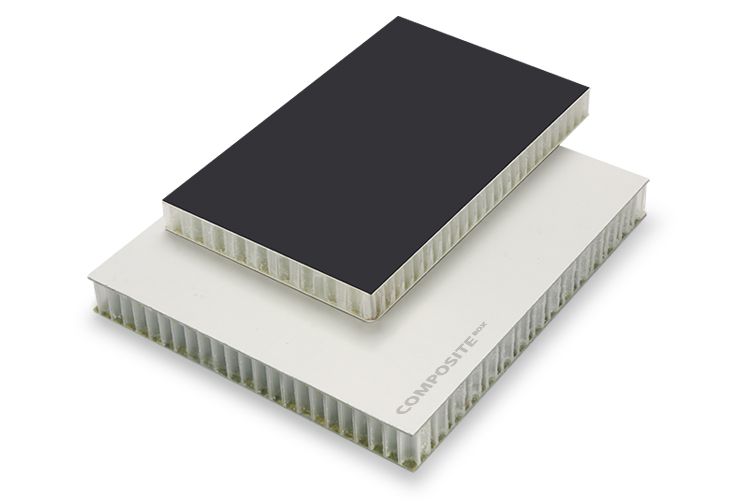

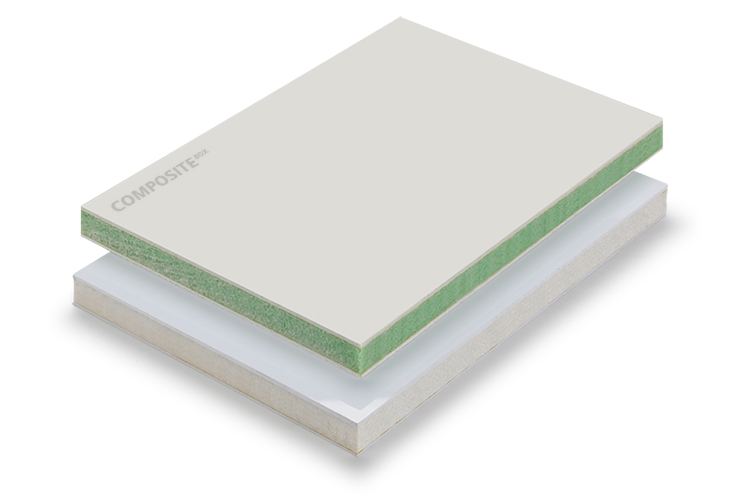

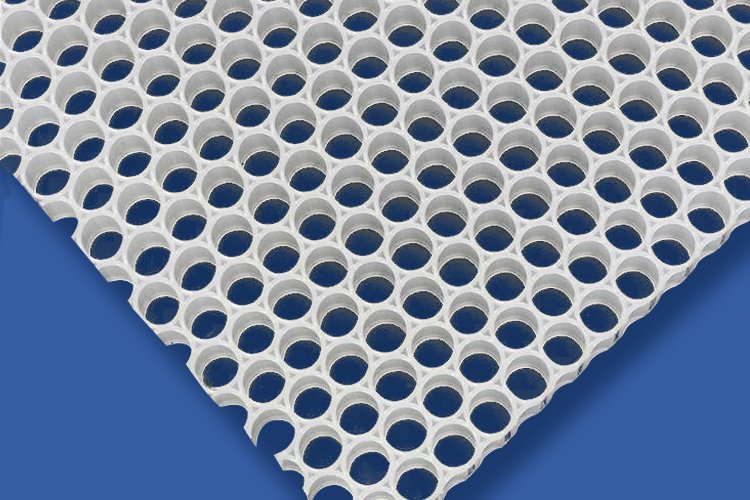

PP (polypropylene) honeycomb panels are high-performance plastic composites. They have a PP honeycomb core with an open honeycomb structure. Both sides are made of FRP (fibreglass) or CFRT skins. They are bonded with adhesives and laminated using a high-pressure vacuum process. Using non-woven polyester fibre mesh makes the bond stronger. It reduces adhesive use and increases adhesion.

PP honeycomb panel is a popular, lightweight material. It has a high strength-to-weight ratio, good sound insulation, and impact resistance. Because it is so versatile, it can be used in lightweight applications such as lorries and ships.

Our PP honeycomb panels are round, rather than hexagonal, allowing for a more even distribution of forces.

advantages:

PP honeycomb panels are foam panels with a hollow, circular structure. They have many advantages.

- Low resin absorption: it improves the material’s stability, durability, and mechanical properties.

- High strength-to-weight ratio: It is extremely lightweight, and ten times lighter than a liquid. It has better compressive strength.

- Recyclable: PP honeycomb is a recyclable and non-disposable material that is also environmentally friendly.

- Good heat resistance: the use temperature can reach 180°F, which is about 82°C.

- Non-absorbent: PP honeycomb hardly absorbs water.

- Durable: PP honeycomb resists corrosion, acids, and alkalis. It is very durable, as well as salt spray resistance and other advantages.

- Stability: PP has a strong molecular structure. Its carbon-hydrogen bonds resist chemical reactions.

- Excellent sound insulation: Polypropylene has a natural low harmonic of 125-150 Hz. This can provide better sound insulation.

Related Product:

Polypropylene Honeycomb Core

FRP PP honeycomb panel consists of top and bottom fiberglass panels and a polypropylene (PP) honeycomb core. It is a lightweight, high-strength material. It has good compression resistance and low deformation.

Applications: It is durable and reliable. It has waterproof, anti-scratch, and impact-resistant qualities.

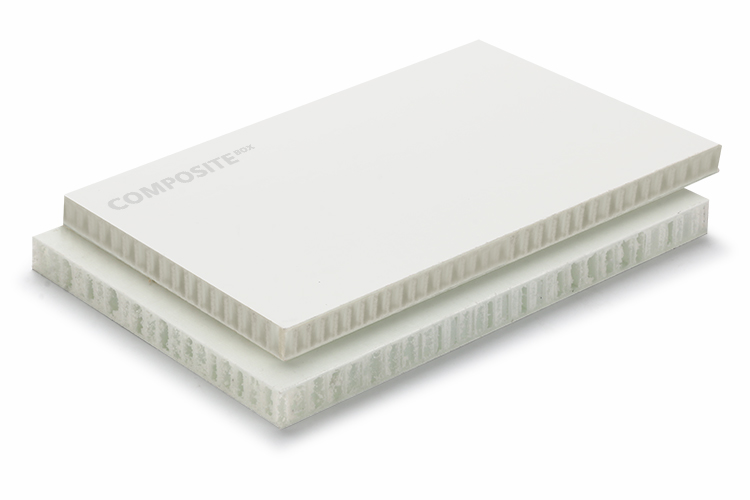

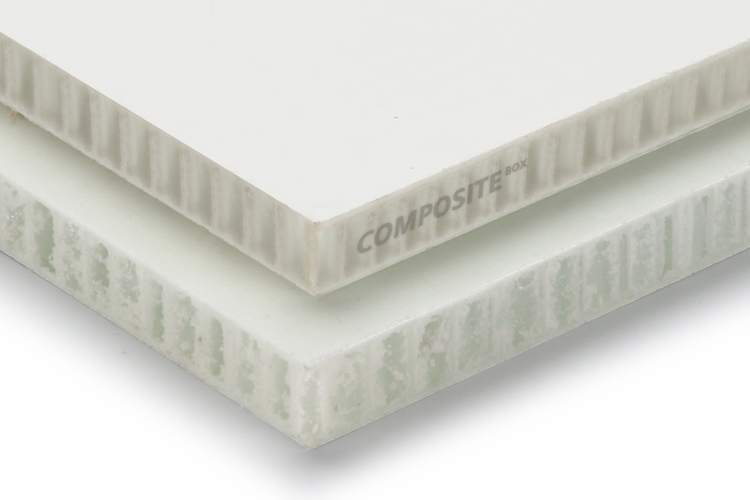

fiberglass PP honeycomb panel

FRP PP honeycomb panel consists of top and bottom fiberglass panels and a polypropylene (PP) honeycomb core. It is a lightweight, high-strength material. It has good compression resistance and low deformation.

Applications: It is durable and reliable. It has waterproof, anti-scratch, and impact-resistant qualities.

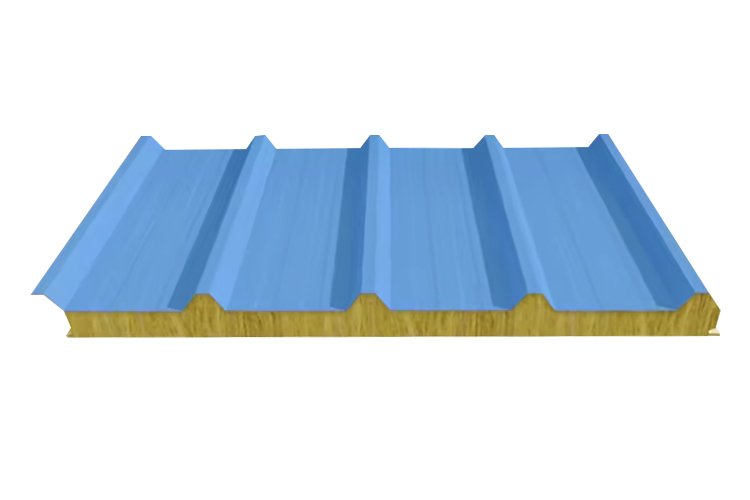

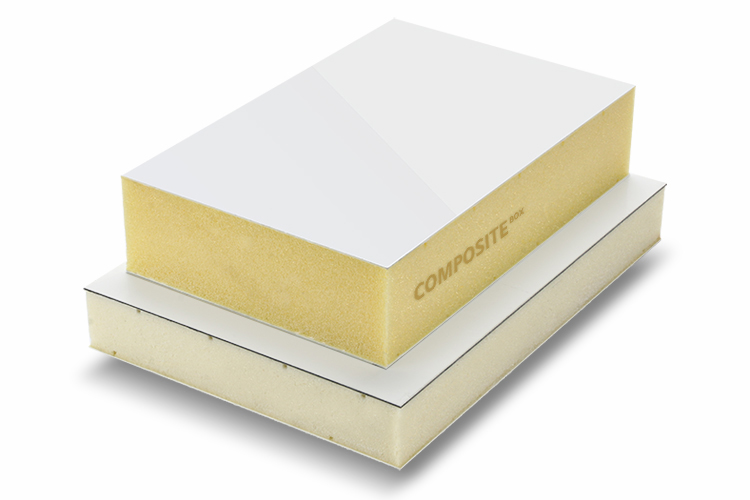

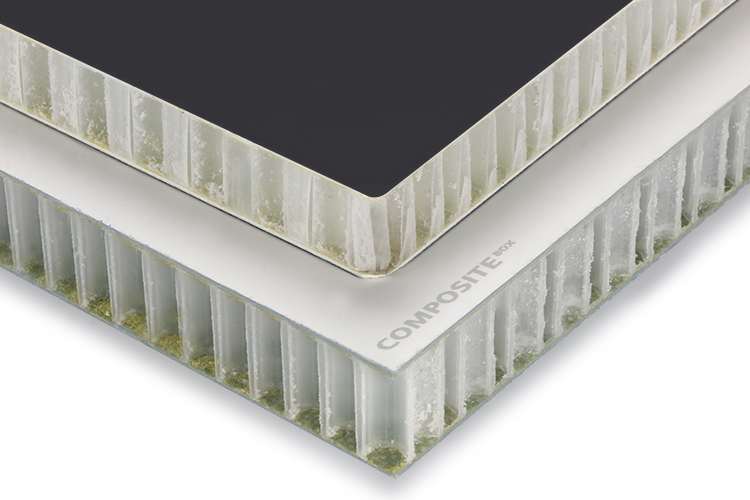

CFRT PP Honeycomb Panel

The CFRT PP honeycomb panel is a high-performance sandwich panel. It has a CFRT (Continuous Fiber Reinforced Thermoplastic Material) layer and a PP honeycomb core. It has a better strength-to-weight ratio than foam board. It is also more bend-resistant and has a higher load capacity. Its mechanical properties are superior, too.

Applications: truck compartments, RVs, and building partition walls, etc.

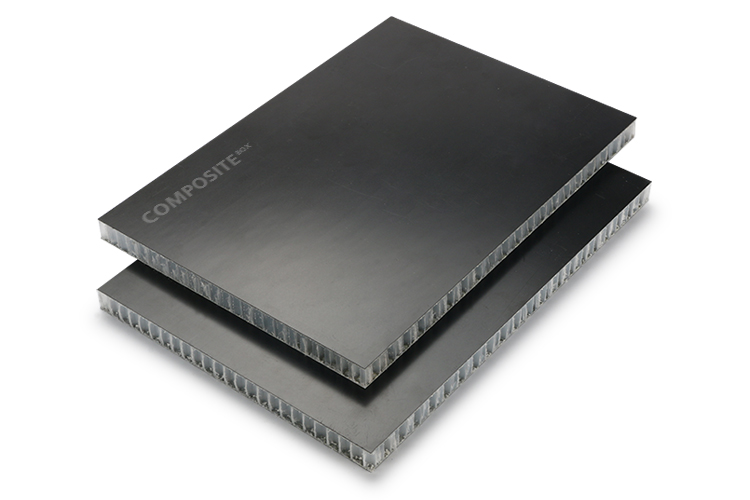

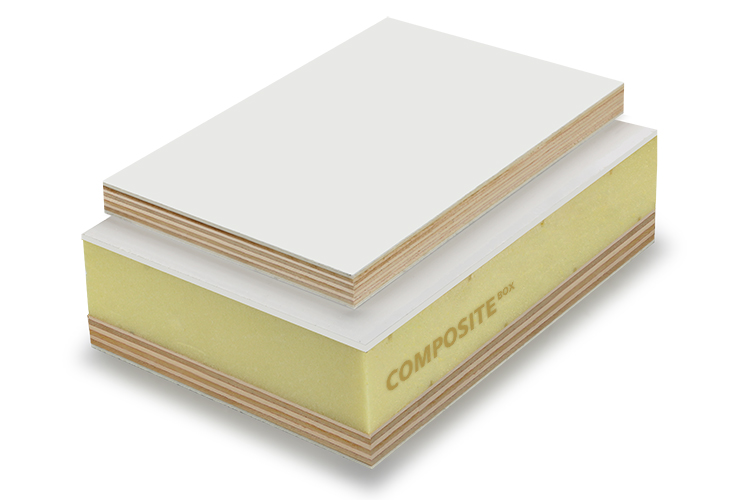

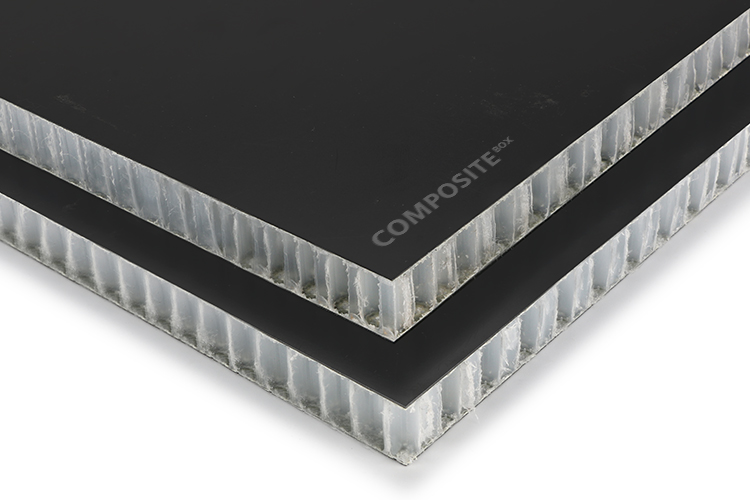

Carbon Fiber PP Honeycomb Panel

Carbon fiber PP honeycomb panels are available in thicknesses of 10 to 20 mm; facing is half or full carbon fiber. Towers are available in 3K, 12K, and 18K, with T300 and T700 options. The core is a polypropylene honeycomb, suitable for high strength, lightweight applications.

Applications:It can be used in pique racquets, cars, yachts, and rowing boats. Also, in other applications that require high performance.

Related Product

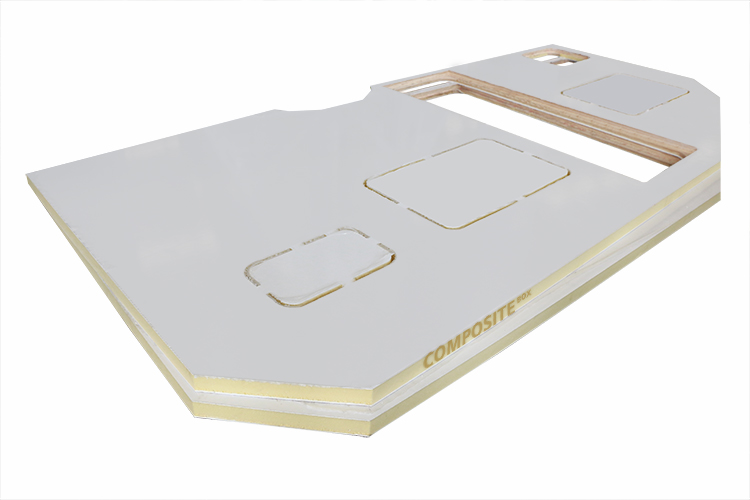

Customized Processing Services

We offer a wide range of OEM and ODM processing customized services.

- Size: length ≤ 12 metres. Width less than or equal to 3.2 metres, thickness 10 mm~100 mm.

- Core layer: can be customized with different thicknesses and density 80~180kg/m³.

- Colour: FRP skin can be customized with RAL colors

- Surface treatment: matte, high gloss, anti-slip

- Surface Coating: A flame retardant or UV resistant coating is added.

- Protective film: PE film as protection.

- CNC: CNC machines cutting and grinding can meet the needs of various industries.

Composite Box

Application of PP Honeycomb Panels :

PP honeycomb panels can be used in many places. These include construction, lorry bodies, houses, and yachts, both indoors and outdoors.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.