CFRT composite sandwich panels manufacturer

About CFRT composite sandwich panels

CFRT composite sandwich panels are high-performance and high-strength sandwich panels. They are laminated by CFRT (multi-layer continuous fiber reinforced tape). It is a lightweight yet strong material. It has better resilience and toughness than FRP. Its fiber length, orientation, and content can be chosen based on demand. Compared with other plastics and metal skins, it has more performance, and compared with FRP, the cost consumption is lower.

CFRT skins are made by high-temperature bonding or thermoforming with various sandwich panels. They can be laminated with PU, XPS, PET, PVC, and other plastics. This makes for a stronger, lighter, high-strength, and more durable material. It is also thinner. It can also be used to produce CFRT plywood and CFRT honeycomb panels. CFRT skins can be laminated with different materials to produce composite panels with different properties, which can satisfy more applications and needs of the industry. It can also be manufactured with FRP skin.

We are the most professional CFRT composite sandwich panel manufacturer; we offer OEM and ODM customized production. Experts for your material selection, we provide 3D drawing design, CNC machining, surface treatment processing, and other services.

advantages:

- CFRT sandwich panels have many performance advantages and are also a cheap material that can replace many traditional sandwich panels.

- Affordable: compared to FRP and aluminum panels, CFRT is much cheaper than those.

- Impact Resistant: CFRT is impact- and crash-resistant and can be bent right back to its original shape.

- Scratch Resistant: CFRT is laminated with continuous fiber-reinforced tape, which has a strong and durable surface.

- Waterproof: Corrosion-resistant and waterproof; even if there is a water leak, the foam core inside will not absorb water.

- Lightweight: CFRP is much thinner than FRP, and at the same weight, CFRT is stronger.

- Long service life: CFRT can protect the inner foam core from external interference and ensure long service life.

- Easy to process: CFRT sandwich panels are easy to process and can be pre-finished for a variety of applications.

Related Product:

CFRT PET composite panel

Characteristics: high strength, durable, lightweight, density of 60–150 kg/m³, and 100% recyclable material.

Application: Widely used in houses, subways, lorries, and airplanes for internal partitions and decoration.

CFRT PU composite panel

Characteristics: made of CFRT and PVC composite, good corrosion resistance, stable chemical properties (40–70 kg/m³)

Application: It can be used in bathrooms, swimming pools, caravan wall panels, marine plywood, and other situations that require corrosion resistance.

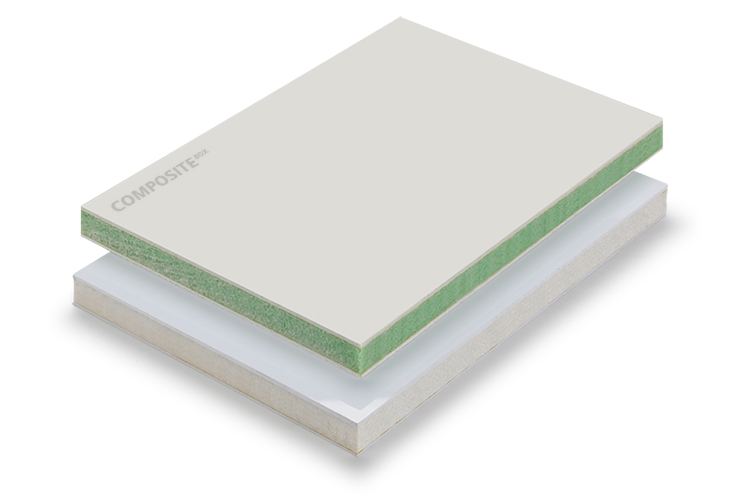

CFRT XPS composite panel

Characteristics: excellent heat insulation, excellent waterproof performance, light density (30–50 kg/m³)

Applications: Can be used for refrigerated trucks, refrigerated trailers, and other applications that require thermal insulation.

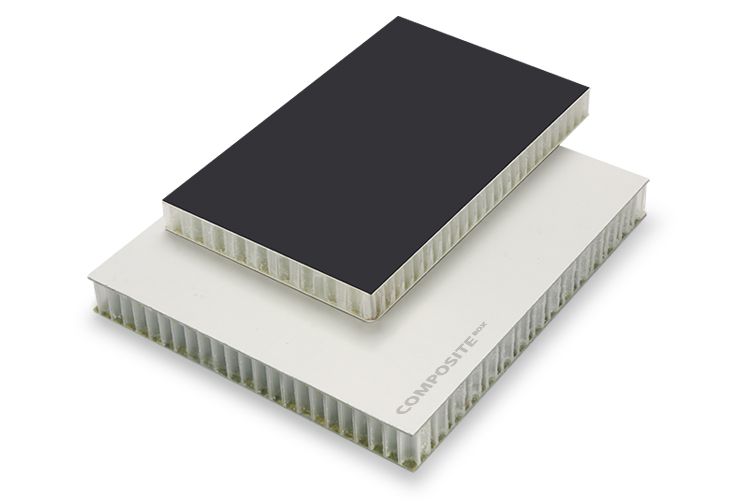

CFRT PP Honeycomb Panel

Characteristics: Excellent impact resistance, very durable, and easy to process.

Applications: suitable for aviation, car boot, caravan flooring, house flooring, etc.

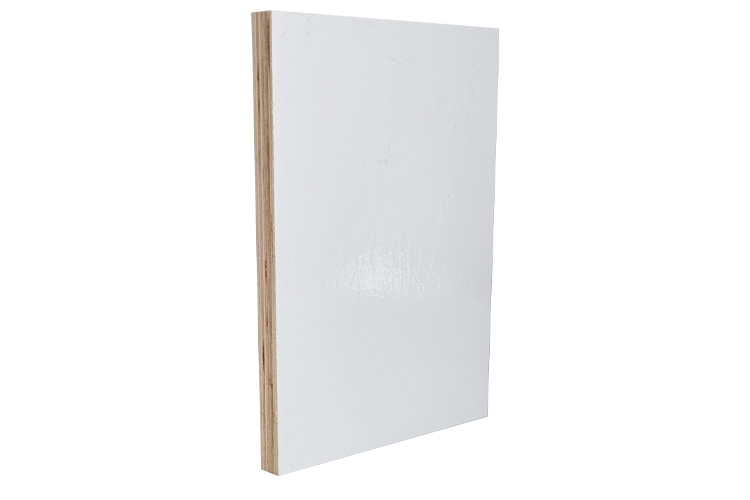

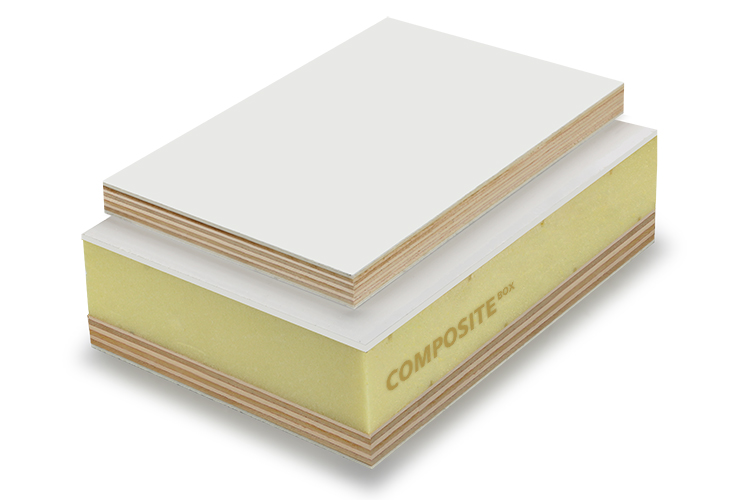

CFRT Plywood Sandwich Panel

Features: A combination of CFRT skin and plywood, very rigid and durable, waterproof and corrosion-resistant.

Applications: Can be used for high-strength applications, such as truck flooring, house flooring, etc.

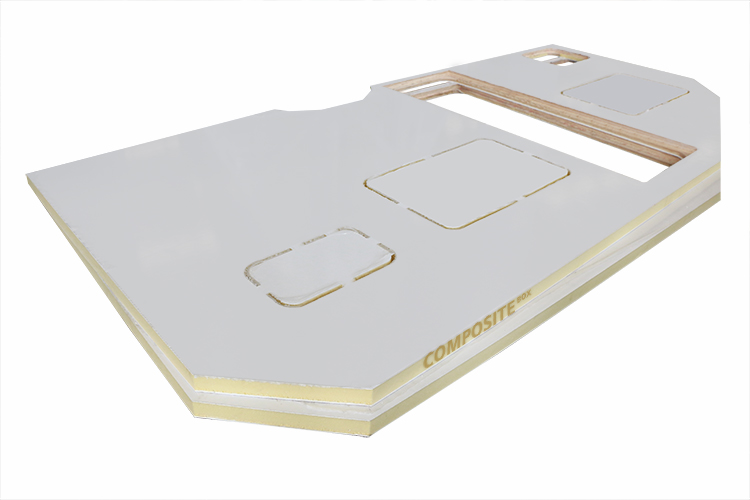

Customized Processing Services

Skin customization: CFRT thickness customization (UD tape 2~9 layers), short cut fiber, continuous fiber, fabric type fiber, resin (unsaturated polyester, epoxy, vinyl), can be FRP skin on the other side:

- Core: Optional foam. Density and thickness can be customized.

- Size: total thickness 10–120 mm, length ≤12 m, width less than or equal to 3.2 m, can be customized according to requirements.

- Surface treatment: matte and high gloss are available; protective film (PET, PVC, PP) can be added.

- CNC processing treatment: CNC cutting services are available.

- Special performance: anti-UV treatment

- Embedded reinforcement: Embedded reinforcement treatment is available; it can add reinforced steel, aluminum tubes, fiberglass, solid wood, etc.

Composite Box

Application of CFRT foam panel :

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.

Technical Parameters

| Attribute | Specification |

|---|---|

| Panel Material | CFRT Board (Thickness: 0.4 ~ 2 mm) |

| Core Material | PET Foam, PVC Foam, XPS Foam, PP Honeycomb Structure Core Material |

| Length | ≤ 12 meters |

| Thickness | 5 ~ 120 mm |

| Width | ≤ 3.2 meters |

| Weight | Custom lightweight design based on thickness and core material |

| Surface Treatment | Optional: Corrosion-resistant, Wear-resistant, UV-resistant |

| Temperature Resistance | High Temperature: Up to 120°C, Low Temperature: -40°C |

| Color Options | Custom colors to meet different environmental and design needs |