Extruded Polystyrene Foam: The Ultimate Guide

XPS foam is a rigid thermoplastic material made from polystyrene, often used in the production of XPS boards and fiberglass XPS foam panels.XPS is made from petroleum products (benzene and ethylene). This underground resource from the “age of the dinosaurs” has given us a wealth of applications. In this article, you’ll learn everything you need to know about the properties and uses of extruded polystyrene.

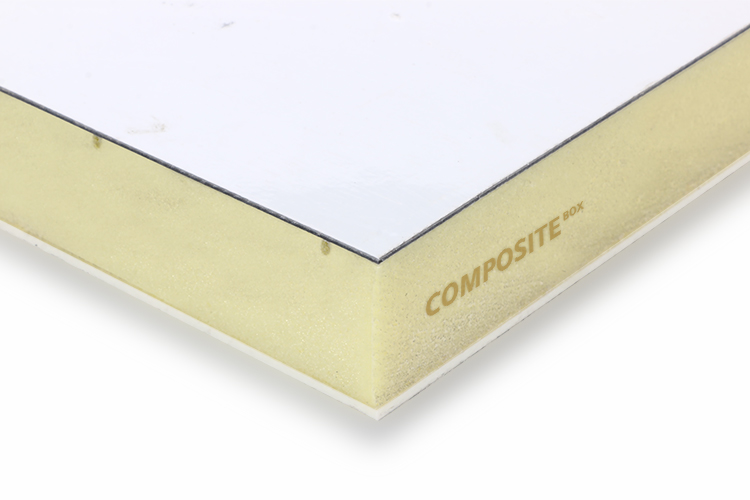

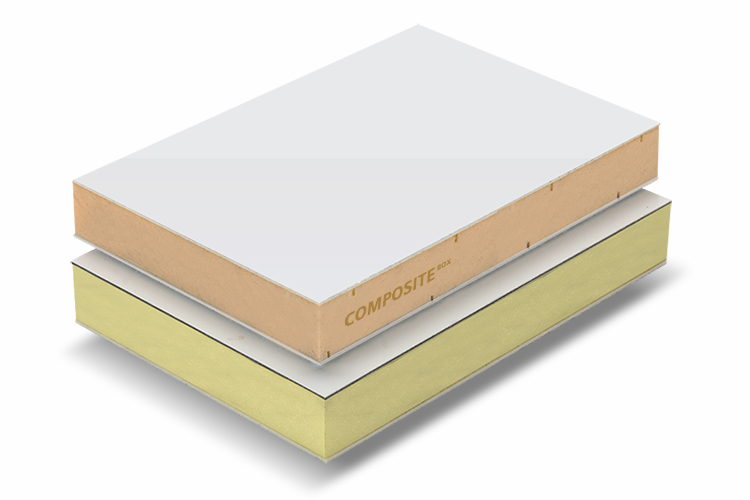

What is XPS foam board?

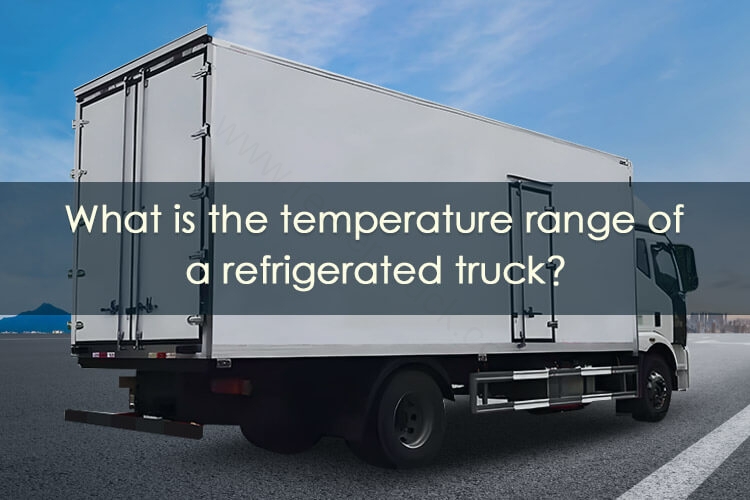

XPS foam is a great closed-cell rigid material. It’s often used for thermal insulation and panels. This foam enhances insulation, helping to preserve heat. It is especially useful for refrigerated trucks, cold storage, and buildings. It has such a good thermal insulation performance thanks to its R-value of 5.0, which can alleviate temperature changes.

In addition to its insulating properties, it is also a lightweight material that can be used in lightweight applications and is required for many modular products. At the same time, it has excellent water and moisture resistance, with an occlusion rate of over 99%, so XPS foam can be used as a replacement for PU foam, EPS foam, and PVC foam, among others.

How is XPS foam manufactured?

Extruded polystyrene foam is produced using an extruder; firstly, you need to prepare the PS pellets, feed the resin pellets into the extruder, melt them, and then add some additive chemicals to the molten mixture, such as dyes, blowing agents, and so on. Using the required heat and pressure, the pellets are extruded through the die mold and wait for cooling and expansion to become the final desired size. After a quality check, including density, appearance, precision, and thermal conductivity, etc., it is determined whether it meets the relevant standards and requirements. The following is the specific process:

Raw material preparation

- Mixing

- Injection of foaming agent

- Extrusion molding

- Cooling and shaping

- Cutting and trimming

- Quality Inspection

- Packaging and warehousing

Foaming agent types: carbon dioxide, butane, dimethyl ether, heavy oil, propane, ethanol.

Advantages of XPS foam insulation board

XPS foam has a lot of features; not only thermal insulation, it is very excellent in terms of service life, durability, and recyclability.

Thermal insulation properties:

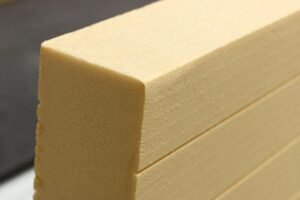

In the same thickness of the insulation material, XPS foam board thermal insulation effect is 2 times higher than that of other insulation materials. XPS R value (insulation coefficient value) is 5; the higher the R value, the lower its thermal conductivity, and its insulation effect depends on its thickness and density; the thicker it is, the weaker the ability to transfer heat. XPS foam is an excellent thermal insulation material with low thermal conductivity.

What is it about XPS foam that makes it such a good insulator? If we take a closer look, we will find that almost every hole in the XPS foam board is closed; it produces a closed-cell cross-section during the production process, and every hole is closed by the PS wall, which helps the XPS foam achieve excellent thermal insulation.

Case: If 100 square meters of residential use XPS insulation board as insulation board, if the use of air-conditioning chiller does not every month save 40 degrees of electricity, if in the cold winter, every month can save 90 degrees of electricity.

Waterproof performance:

The waterproof performance of extruded polystyrene foam is unquestionable. It can well resist the entry of moisture because it is a closed cell structure; very low permeability can work stably in humid and outdoor. the permeability of XPS foam is about 1.0, which makes it a class 2 semi-permeable moisture-proof layer. It is highly resistant to moisture and can quickly release moisture even if it is absorbed.

XPS is good at resisting compression

XPS insulation has high compression resistance and can withstand pressures up to 300 kPa with a deformation rate of less than 12%, making it ideal for use in scenarios with high strength requirements and suitable for the following applications:

- Walls

- Refrigerated truck

- Caravan panels

- Roofs

- Floor insulation

Recyclable:

XPS foam is recyclable, but not biodegradable. After recycling, the resin can be melted down and remade into new XPS insulation panels.

Reduced emissions:

XPS foam has highly efficient thermal resistance properties that can be used for buildings, refrigerated trucks, etc., to reduce CO2 emissions further.

Is extruded polystyrene insulation board toxic?

Extruded polystyrene insulation board is non-toxic and safe to touch. No harmful substances are made during manufacturing. The product has no toxic volatile organic compounds (VOCs).

As long as XPS is prevented from catching fire, it is absolutely safe!

Application of XPS foam board

XPS foam has excellent thermal insulation and waterproofing properties, making it suitable for use in high-strength applications that require thermal insulation.

Used in the construction industry

Commonly used in homes and buildings, it can be used to insulate roofs, floors, and walls. It is easy to use, and the construction process is very easy because it is a lightweight material.

Refrigerated truck body

Used in refrigerated trucks and trailers, it can be used as an insulating panel for the body, which provides good insulation and reduces internal temperature fluctuations, ensuring that the product reaches its destination safely and preventing foodstuffs from spoiling due to temperature fluctuations.

Caravan Body

XPS foam for caravan bodies maintains the internal temperature, making the air conditioning’s cooling and heating functions more efficient and the camping experience more comfortable.

Formulation of XPS

| Serial Number | Raw Material | Specification | Percentage |

|---|---|---|---|

| 1 | PS Pellets (Virgin or Recycled) | MFI (Melt Flow Index) preferably between 3-15 | 90-95% |

| 2 | Carbon Dioxide | Industrial grade, purity ≥99% | 0-4% |

| 3 | Ethanol | Industrial grade, purity ≥99% | 0-4% |

| 4 | Dimethyl Ether/Butane | Isobutane | 0-4% |

| 5 | Masterbatch | Carrier: GPPS (General Purpose Polystyrene) preferred | 0-1% |

| 6 | Nucleating Agent | Talc powder finer than 1000 mesh | 0-5% |

| 7 | Flame Retardant | (No specific type specified) | 0-5% |

What is the difference between expanded polystyrene and polystyrene?

Extruded polystyrene has a stronger closed cell structure, is denser than expanded polystyrene, and is more moisture resistant; read this article to learn more about expanded polystyrene.

What does closed-cell structure mean?

The closed-cell structure of XPS foam provides both waterproofing and insulation. This means the interior consists of numerous independent microscopic cells that do not interconnect, forming a uniform honeycomb pattern. Consequently, it offers exceptional waterproofing and moisture resistance, along with superior compressive strength that effectively blocks water and gas permeation.

What are the disadvantages of XPS foam?

XPS extruded polystyrene is an excellent material suitable for most applications and has earned a good reputation. However, it still has some drawbacks. For example, it has high manufacturing costs, releases hydrofluorocarbons, is flammable, and is prone to shrinkage. These factors may pose certain challenges in environmental protection and construction, making them key areas of industry focus.

High Cost:

XPS foam production requires specialized equipment and unique foaming agents, resulting in manufacturing costs and market prices consistently higher than other insulation materials. This limits its widespread adoption in large-scale, cost-sensitive projects.

Hydrofluorocarbon Emissions:

Traditional XPS foam uses hydrofluorocarbons as foaming agents. During production and disposal, these substances may release greenhouse gases, contributing to environmental pollution and the greenhouse effect. Environmentally friendly alternative technologies are urgently needed.

Flammability:

The material itself is susceptible to high temperatures or open flames. When burned, it may release harmful gases. Although some products incorporate flame retardants, their fire resistance ratings remain limited, necessitating additional safety measures in construction.

Potential Shrinkage:

Under extreme temperature fluctuations or prolonged stress, XPS foam boards may shrink or crack, compromising the building’s overall airtightness and insulation effectiveness. This tendency is particularly noticeable during the initial construction phase.

Poor UV Resistance:

Long-term sun exposure causes XPS foam board surfaces to age and become brittle. Protective coatings are required; otherwise, structural performance degrades, maintenance costs rise, and material lifespan shortens.

Non-Biodegradable:

As a plastic material, XPS foam decomposes extremely slowly. Discarded boards persistently pollute soil and the environment. Low recycling rates negatively impact ecological sustainability.

FAQ:

Can XPS foam be recycled?

XPS foam is recyclable. It is typically reduced in volume through mechanical compression and then pelletized into new plastic products. Future advancements in recycling processes may further enhance recovery and utilization rates.

Can XPS foam be cut to specific dimensions?

XPS foam can be cut mechanically or manually to achieve desired thickness, length, and width. Sharp knives or milling cutters are suitable for processing. It meets requirements for applications like refrigerated trucks and construction.

What is the lifespan of XPS foam?

The lifespan of XPS foam depends on the actual environment. Under stable conditions—free from UV exposure, mechanical damage, extreme temperatures, and susceptible to decomposition or mold—it can last over 30 years.

What is the R-value of XPS foam?

XPS foam has a standard R-value (thermal resistance) of approximately R=5.0 per inch of thickness, with a thermal conductivity of about 0.027–0.03 W/m·K. This indicates excellent thermal insulation capability. Length and thickness can be customized to achieve target insulation performance. Compared to EPS and other foam materials, XPS offers a slight R-value advantage, making it widely adopted in cold and humid environments. It delivers particularly outstanding energy-saving insulation for floors, walls, and roofs. Actual insulation effectiveness is proportional to panel thickness, requiring selection based on project parameters.

Related Post

Related Product

Author introduction

Hello, customers

My name is Jack Yu and I am the Business Manager of Composite Box. I have been in the business of sandwich panels, refrigerated trucks and RVs for more than 10 years. Please feel free to contact us. I am happy to provide you with the best service and products.

Email: info@composite-box.com | Tel: 86+17280837525