Box Truck Size Guide: Finding the Right One

Box trucks are indispensable transportation vehicles in the logistics industry, widely used in scenarios such as moving, urban delivery, and cold chain transportation. Their primary advantages lie in their compact structure and convenient loading/unloading capabilities, providing excellent protection and efficient transport for various cargo types. Mainstream box trucks on the market come in diverse sizes, primarily ranging from 10 feet to 26 feet, with each size featuring distinct structural designs and application scopes. In recent years, fiberglass composite (FRP) technology has rapidly advanced in box body manufacturing. FRP composites not only make the vehicle body lightweight and corrosion-resistant but also significantly enhance insulation and strength, extending the vehicle’s service life. Furthermore, the integration of high-performance polyurethane (PU) foam and PET materials further improves the overall performance of refrigerated and dry cargo compartments.

Classification of Box Trucks

Box trucks are typically categorized into the following types: straight trucks, cube trucks, Luton vans, refrigerated box trucks, multi-temperature zone trucks, and dry freight box trucks. Each model exhibits slight variations in structural design and dimensional options.

- Straight Truck / Cube Truck: Commonly used for urban distribution and moving services. The cargo body typically features an FRP exterior paired with composite sandwich panels, generally 10mm to 50mm thick, offering impact resistance and corrosion resistance.

- Luton Trucks: Feature an extended “Luton Peak” roof section, typically 14FT or 16FT, providing additional space ideal for transporting bulky furniture and cost-effective moving services.

- Refrigerated Trucks: Utilize FRP fiberglass and polyurethane foam panels as core materials, with thicknesses exceeding 50mm. These trucks offer lighter overall weight while maintaining excellent thermal insulation, making them suitable for transporting frozen foods, pharmaceuticals, ice, and similar goods. FRP polyurethane foam panels are non-absorbent with low thermal conductivity, maintaining a controlled temperature range of -18°C to 0°C while providing effective waterproofing and mold resistance.

- Dry Cargo Compartments: Primarily utilize FRP PET foam panels as sandwich layers. PET panels offer high strength, lightweight properties, and environmental sustainability through recyclability. Suitable for transporting furniture, daily necessities, and industrial goods, with common thicknesses ranging from 20mm to 40mm.

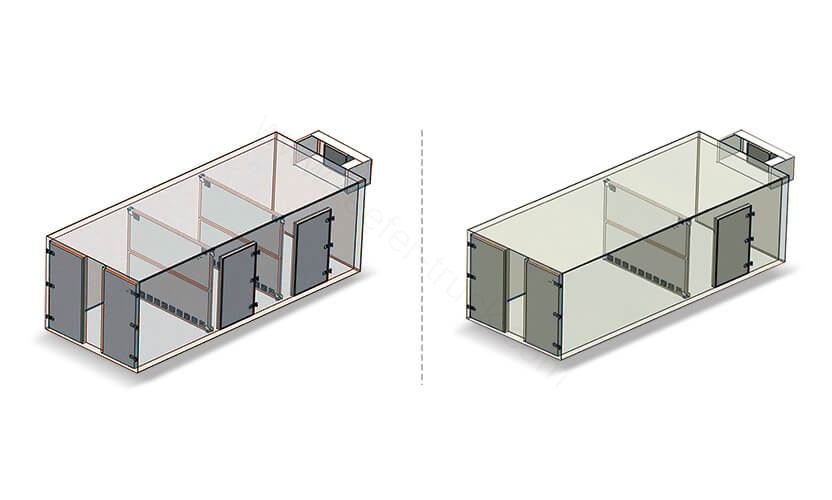

- Multi-Zone Refrigerated Trucks: Supports zoned temperature control, suitable for simultaneous transport of frozen and ambient goods. Common sizes include 16FT, 20FT, and 24FT. Insulation thickness can be customized based on cargo requirements to achieve multi-space, multi-temperature management.

Each model offers selectable FT specifications to match logistics needs, with customizable options including liftgates, side doors, shelving, and E-track systems.

What are the dimensions of box trucks?

The mainstream dimensions of box trucks range from 10 feet to 26 feet. These varied sizes offer significant operational flexibility, serving as a key factor in the logistics industry’s operational efficiency and cargo adaptability.

Standard sizes

| Size (FT) | Length (m) | Volume (cu ft) | Typical Applications | Payload (lbs) |

|---|---|---|---|---|

| 10FT | 3.2 | 600 | Urban delivery, express, e-commerce | 3,200-4,000 |

| 14FT | 4.3 | 1,000 | Small moving, groceries, furniture | 5,000-6,500 |

| 16FT | 4.88 | 1,300 | Luton truck moving, cold chain transport | 7,000-8,500 |

| 20FT | 6.1 | 1,500 | Medium enterprise delivery, refrigerated truck | 10,000-12,000 |

| 22FT | 6.7 | 1,700 | High-value goods or cold chain relocation | 12,000-14,000 |

| 24FT | 7.3 | 1,800 | Bulk transport, cold chain, multi-temperature zones | 12,000-15,000 |

| 26FT | 7.92 | 2,000+ | Long-distance moving, bulk materials | 14,000+ |

| 28FT+ | >8.5 | 3,500+ | Exhibition equipment/industrial goods/specialized cold chain | Custom |

10FT Box Truck

Ideal for express delivery, urban distribution, and small-batch e-commerce shipments. Its lightweight construction and flexible tailgate configuration enable easy loading/unloading, allowing seamless navigation through city alleys.

14FT Box Truck

The top choice for small-scale moving, grocery delivery, and market vendors. Accommodates most household furniture, with interior shelving and E-track straps available upon request.

16FT Box Truck & 16FT Luton Van

The 16FT model is a cost-effective choice for moving and less-than-truckload freight. The Luton van features an extendable roof, making it especially convenient for loading large items like mattresses. The 16FT refrigerated truck is ideal for transporting food and pharmaceuticals. It uses thickened FRP polyurethane sandwich panels to ensure temperature control throughout the journey, offering flexible loading and low energy consumption.

20FT Box Truck

Ideal for bulk distribution or supermarket restocking. Refrigerated models utilize thicker FRP foam panels for multi-temperature compartmentalization, enabling simultaneous transport of fresh produce, frozen goods, and daily necessities—significantly boosting operational efficiency.

22FT~24FT Box Truck

The 24FT refrigerated truck supports multi-temperature zone technology, internally partitionable into two to three independently temperature-controlled compartments for transporting frozen, refrigerated, and ambient goods. Dry cargo variants utilize FRP PET sandwich panels—eco-friendly and durable—suited for bulk shipments of furniture, appliances, and building materials.

26FT Box Truck

Ideal for large-scale bulk transport, corporate relocations, and specialized logistics, accommodating entire offices or multiple furniture sets. The refrigerated variant maintains constant temperatures down to -20°C, featuring insulation up to 80mm thick with PET or PU foam filling and a volume exceeding 2000 cubic feet.

Super-Large (28FT and above)

Designed for professional freight companies, exhibition setup, specialized industrial goods, and extended cold chain transportation. Customizable space and multi-temperature configurations support mixed cargo loading and end-to-end temperature control.

The Impact of Box Truck Dimensions

Box trucks of various sizes exhibit distinct differences in operation and loading:

Loading Efficiency and Delivery Flexibility:

10-foot and 14-foot models offer high maneuverability, making them ideal for urban express delivery and high-frequency short-distance distribution. Their moderate space prevents both underloading and overloading, enhancing per-vehicle utilization.

16-foot and larger sizes support loading more pallets and bulky items in a single trip, reducing loading frequency and making them suitable for bulk transport or large-scale moving.

Transportation Costs and Energy Consumption:

Larger models (20FT-26FT) significantly increase per-trip cargo capacity, lowering unit shipping costs. However, they consume more fuel and demand greater maneuverability for turning and parking, making them best suited for professional drivers and long-distance hauling. Smaller models offer lower fuel consumption and superior road network adaptability, ideal for frequent access to urban core areas.

Cargo Protection & Temperature Control:

Refrigerated models feature FRP + PU foam panel construction with customizable insulation thickness, ensuring minimal temperature fluctuations for food or pharmaceuticals. Dry cargo models use FRP + PET foam panels—lightweight, eco-friendly, and capable of withstanding high loads and impacts to safeguard goods.

Advantages of Multi-Zone Compartments:

22FT, 24FT, and 26FT multi-zone refrigerated trucks allow flexible space division for separate transportation of different goods, significantly improving cold chain delivery efficiency and reducing multiple trips.

Regulatory & Licensing Requirements:

Models 26FT and above typically require a Commercial Driver’s License (CDL), with strict weight and volume restrictions. Businesses must consider driver qualifications and actual transportation needs when selecting models.

Ongoing Operation, Maintenance & Expansion:

Modular design enables rapid assembly and maintenance for mainstream FT-sized box trucks. Specifically tailored for cold chain and multi-temperature applications, this significantly optimizes the transportation chain and equipment investment returns.

Applications for Different Types of Box Trucks and Multi-Temperature Zone Trucks

Small Box Truck (10-14FT)

Ideal for urban express delivery, e-commerce warehousing and distribution, and community moving services. Offers flexible space, low fuel consumption, and can navigate narrow streets.

Medium Box Truck (16-20FT)

Balances capacity and maneuverability, suitable for medium-volume deliveries, supermarket restocking, and regional warehouse transfers. The 16-foot Luton truck is particularly well-suited for moving services and transporting lightweight goods.

Large/Heavy-Duty Box Trucks (22-26FT and above)

Ideal for bulk materials, construction supplies, and school/corporate relocations. Refrigerated models support large-scale food and pharmaceutical transport, enabling efficient multi-temperature and multi-category deliveries in a single trip through effective compartmentalization.

Multi-Zone Refrigerated Trucks

Primarily available in 20FT, 24FT, and 26FT refrigerated models, these vehicles feature customizable multi-zone interiors. Independent temperature control units ensure simultaneous transport of frozen, refrigerated, and ambient goods, enhancing operational flexibility for cold chain enterprises.

Key Factors Influencing Box Truck Selection

Cargo Volume and Weight: Select appropriate dimensions and structural types based on actual loading requirements to avoid resource waste or overloading.

Transport Distance and Route: Small or medium-sized models are recommended for urban road networks, while 24FT or larger models are advised for long-haul and interprovincial routes.

Driver’s License Requirements and Regulatory Compliance: Vehicles 26 feet or larger typically require a Commercial Driver’s License (CDL). Businesses must ensure drivers meet qualification standards.

Operational Efficiency and Additional Features: Consider turning radius, loading/unloading convenience, liftgate availability, and multi-temperature compartmentalization based on specific operational needs.

Box Trucks vs Cargo Vans

Box trucks offer advantages over cargo vans in terms of larger volume, a separate cargo compartment, and greater capacity for bulk transport. They also provide superior cargo security, insulation, and customizable space. Cargo vans are better suited for short-distance delivery of small parcels, offering high flexibility but with limited payload capacity.

Differences in Dimensions Between FRP and Aluminum Cargo Compartments

For refrigerated vehicles, FRP fiberglass with polyurethane foam panels is recommended as the sandwich layer, with thicknesses ranging from 50-80mm. This offers excellent thermal insulation, moisture resistance, and corrosion protection, making it ideal for cold chain transportation. Dry cargo models primarily use FRP PET panels, which are lighter yet highly durable, suitable for bulk cargo and high-load applications. Aluminum panel bodies are commonly found in dry cargo vehicles. While lightweight, their thermal insulation is inferior to composite materials. With standard thicknesses of 1-3cm, they are suitable for general cargo transport but do not perform as effectively as FRP materials in extreme environments or cold chain logistics applications.