Caravan Composite Panels

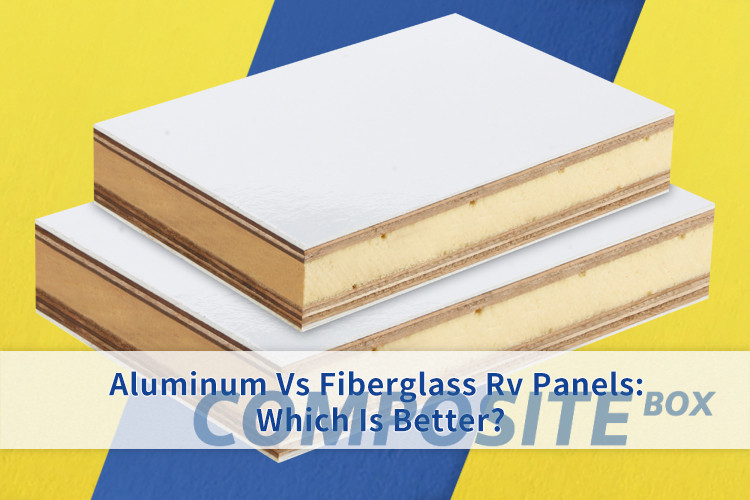

Caravan composite fiberglass panels make the vehicle lighter. This boosts driving efficiency and convenience. A leading foam composite panel structure cuts weight. This fixes issues from excess weight. Too much weight can harm driving performance. The fiberglass foam structure replaces traditional materials. Composite Box also provides CNC machining and design services for caravan composite materials. This makes it easier for DIY caravan dealers.

We provide caravan roof panels, siding panels, and floor panels. We offer a complete range of composite materials. Experience our one-stop manufacturing process. We are a reliable caravan supplier and manufacturer.

Product Description

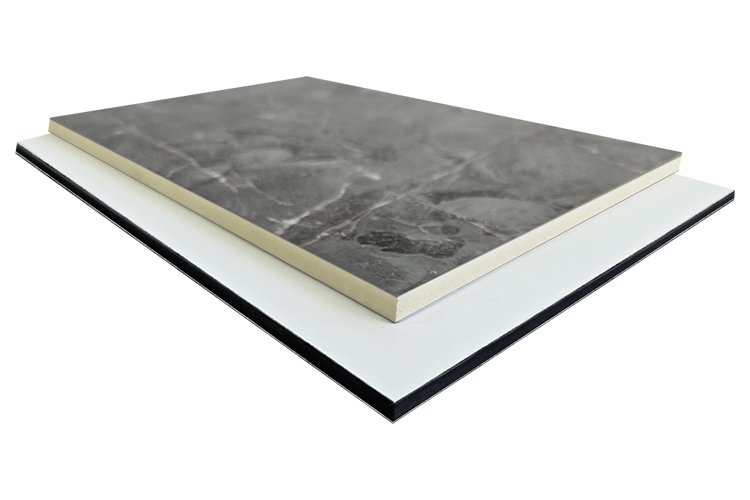

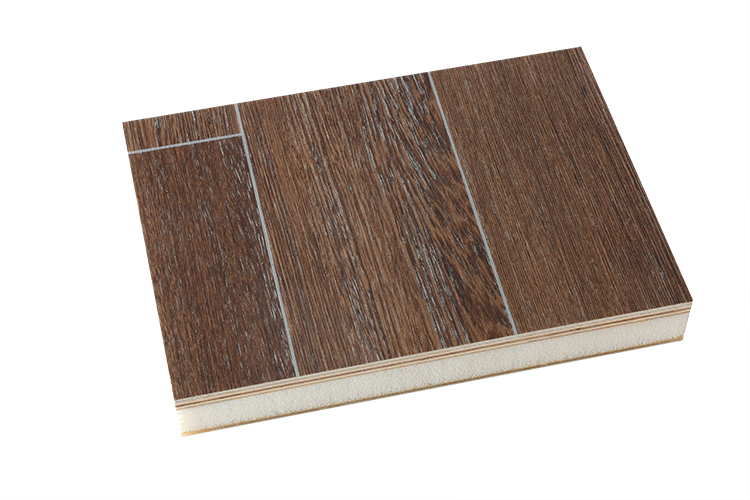

Caravan composite panels have a multi-layer design. They feature a fiberglass skin or a new continuous fiber (CFRT) on the outside. The core material uses closed-cell rigid foam, PP honeycomb core, etc. High-pressure composite. We provide CNC machining. It can create reserved spaces for doors, windows, wires, pipes, and other items ahead of time. We also provide corner aluminum profiles. We deliver aluminum alloy structures to take the place of wooden slats and tin plates in caravans. Delivered via CKD (completely knocked down) assembly, they are not only easy to install but also easy to transport.

Our composite panels offer a smooth and seamless design. They don’t have rivets, which adds to their clean look. The glossy surface and integrated molding process make them visually striking. We support customization for various shapes, including fully customizable, foldable, and irregular shapes. They offer insulation and thermal performance. This keeps internal temperatures cozy in cold winters and cool in hot summers, improving travel comfort. This makes our products highly popular.

Caravans produced using our composite panels have excellent performance. The use of composite materials reduces environmental pollution and is recyclable. They can be used in high-temperature environments and are resistant to UV radiation, making them less prone to aging and fading. Fiberglass has strong impact resistance and scratch resistance and is easy to maintain. With over 20 years of experience in caravan production, we are delighted to offer our services to you.

Advantages

- Durable

- Improved fuel efficiency

- Easy maintenance

- Thermal insulation

- Impact resistance

- Environmentally friendly

Parameters

| Product Name | Composite Panel for Caravans |

|---|---|

| Surface Material | FRP Sheet, CFRT (Continuous Fiber) |

| Core Material | XPS, PU, PVC, PET, PP Honeycomb |

| Maximum Length | 11.8 meters |

| Maximum Width | 3.2 meters |

| Thickness Range | 8 to 110 millimeters |

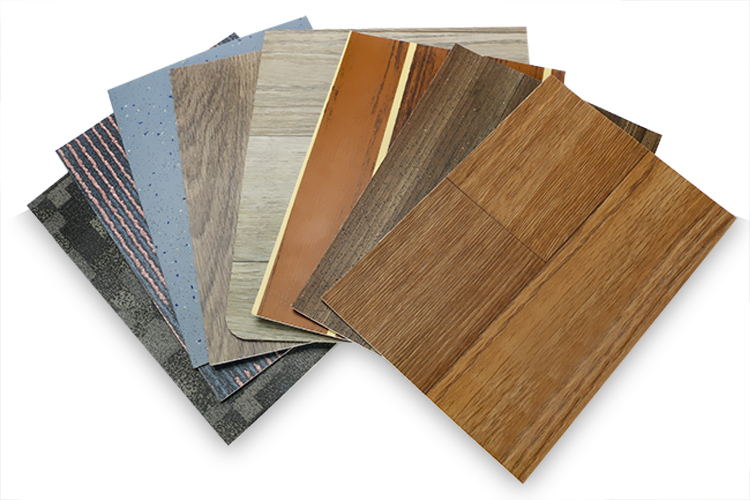

| Available Colors | RAL Color Series |

Get Free Quote of Caravan Composite Panels

advantages

- High density: High-density rigid PVC panels offer high strength.

- Thermal insulation: They provide efficient thermal insulation.

- Fire resistance: PVC has flame-retardant properties, helping to prevent the spread of fire.

- Excellent insulation: PVC panels offer good electrical insulation properties.

- Environmentally friendly: PVC panels are recyclable.

- Attractive appearance: They have a smooth surface.

- Easy to process: They can be easily milled, cut, stamped, formed, and painted.

- Durability: Resistant to corrosion from acids, alkalis, and chemicals

- Versatility: Suitable for advertising displays, signage, printing, and furniture panels

Applications

- Advertising printing: signboards, nameplates, printing plates, billboards.

- Furniture: cabinets, furniture boards, decorative boards.

- Construction: decorative strips, structural materials, columns.

- Industry: automobiles, ships, aircraft.

Customization Options for High-Density PVC Sheets

High-density PVC sheets are available in custom sizes: We offer customized thicknesses and dimensions to suit your needs. We can design the appropriate sheet dimensions for your project, regardless of its application.

- Thickness: 3–50 mm, standard thicknesses (0.4 inches, 0.8 inches, 1 inch, 1/8 inch, 1/2 inch, 1/4 inch, 3/16 inch, 3/4 inch, and 3/8 inch)

- Width: 3.6 meters

- Length: 11.8 meters

Surface Treatment: To cater to a wide range of market needs, we have developed various surface treatments and finishes. We offer color customization in black, white, brown, and gray, among others. We also provide different material finishes, such as embossed finishes and vinyl flooring. We strive for both stylish aesthetics and enhanced performance, improving visual appeal and functionality. These finishes not only enhance appearance but also provide anti-slip properties, increase durability, and extend service life.

vedio

FAQ

related Product

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.