Plywood Foam Panel Manufacturer

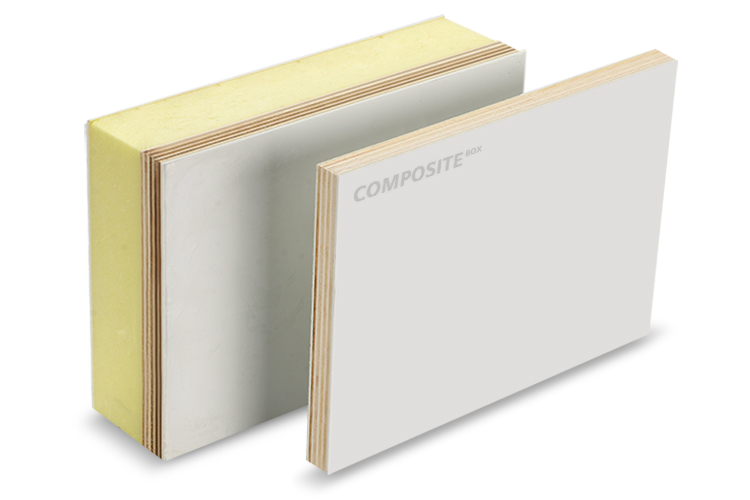

Plywood foam composite panels are strong materials made from fiberglass, aluminum, rigid foam, and plywood. It is an ultra-high-strength material that surpasses steel and aluminum panels. It is a combination of waterproof, high-strength, heat preservation, and beautiful material. Solve the deficiencies of plywood and foam panel. Suitable for applications in harsh environments.

Features

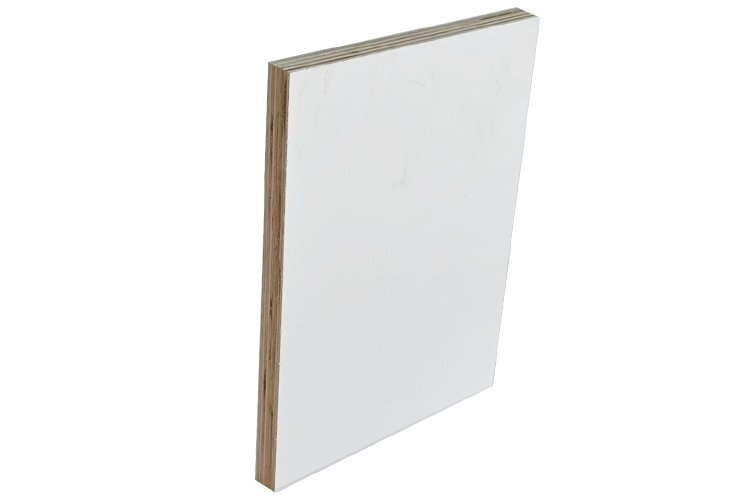

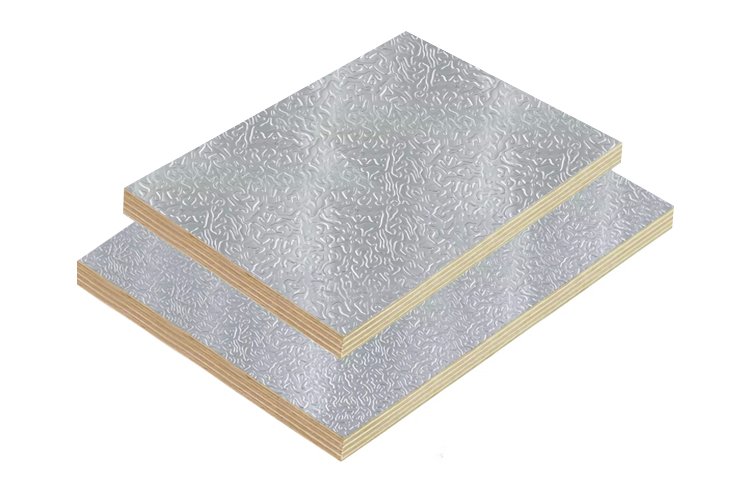

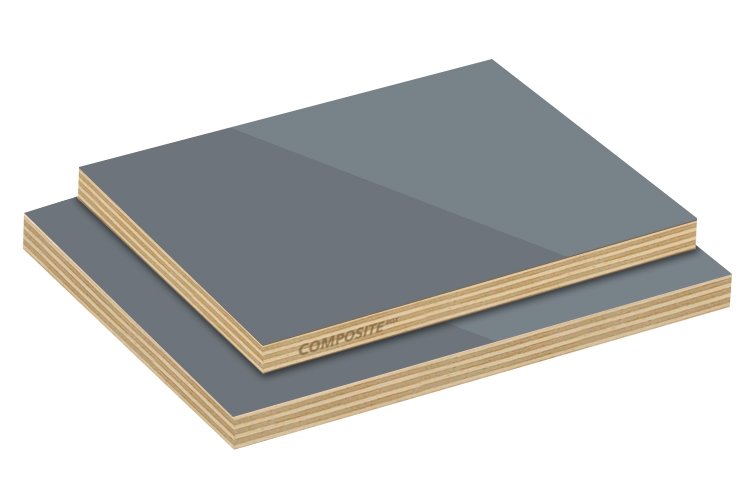

Plywood foam panels use fiberglass as a skin. It is a lightweight material, and we offer a variety of customized options. We offer 20~150mm thickness, able to customize the thickness of the core and plywood. We provide 0.7~5mm fiberglass skin, which is anti-scratch and waterproof. We provide marine grade plywood with a thickness of 3~40mm.

Get Free Quote of Plywood Foam Panel

structure

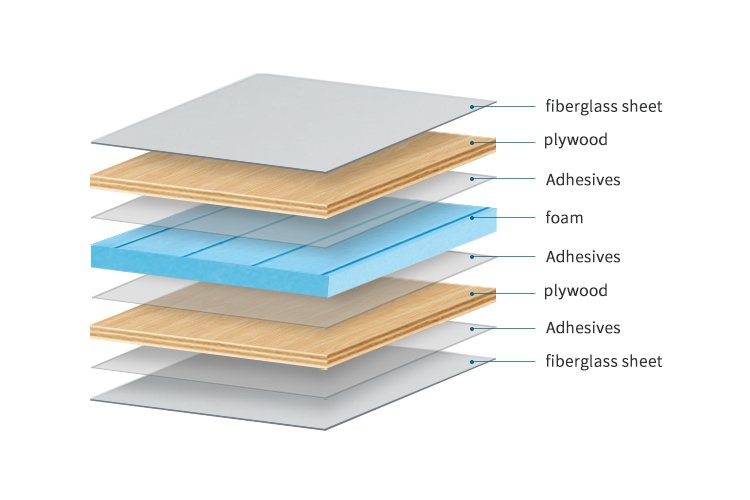

lywood foam panels are high-strength materials suitable for high-frequency and harsh environment applications. Their structure can provide different strengths. The following is their structure:

- Fiberglass sheet: a composite material made of fiberglass and resin that provides water and moisture resistance, thermal insulation, bending resistance, and high strength, which can provide effective protection for plywood foam panels. If you wanna read more about “fiberglass sheet” and you can click this page.

- Aluminum sheet: Uses aluminum alloy sheet as the reinforcing structure inside the composite material. It is capable of providing high strength and lightweight properties. Adaptable to high-frequency applications.

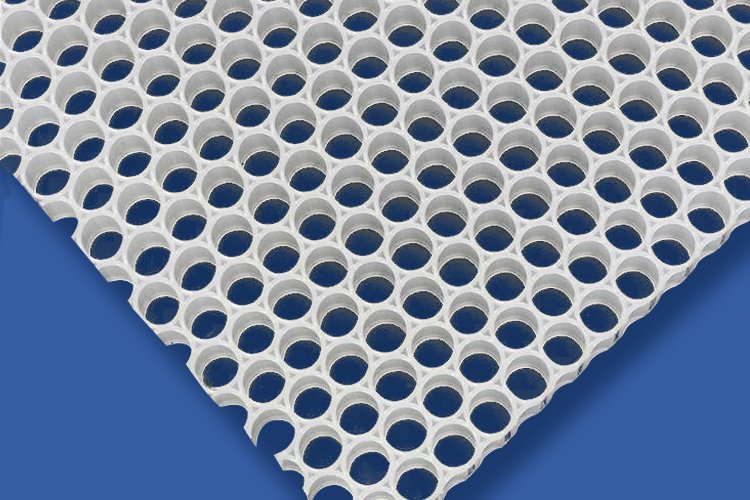

- Foam board: it is an easy-to-process, low-density insulation foam.

- Plywood: Plywood consists of pine, fir, spruce, birch, oak, and maple. It can improve the utilization of wood. It usually has 3 to 11 layers. It offers effective bending resistance, high strength, and other benefits.

No matter which application you use it in, we can provide you with customized material construction. If you use it for RVs, we can provide decorative plywood foam board. If you are using it for furniture manufacturing, we can produce 20mm HPL plywood veneer foam sandwich panels for you. We have 30+ in-depth applications, so feel free to establish a relationship with us if needed.

Advantages

- Super High Strength: 3 materials are used to make the composite sandwich panel, which enhances the strength and is not easy to deform or break.

- Long life: This composite material can last longer than traditional composites; it has a service life of more than 20 years.

- Easy to maintain: Whether it is fiberglass, aluminum, or HPL, it is easy to maintain, reducing costs and maintenance frequency.

- Durable: plywood foam panels, which can be combined with a variety of materials. They have excellent scratch resistance and anti-aging properties.

Parameter

| Category | Options |

|---|---|

| Name | Plywood Foam Panels |

| Foam Core | PET foam, PVC foam, PU foam, XPS foam, PP honeycomb |

| Core | Marine-grade plywood, available in 3–11 layers, 3–18mm thickness |

| Gel Coat | Optional gel coat |

| Fiberglass Type | Short-cut fiber, woven fiber |

Application

Foam Plywood Panel applications:

- RV: travel trailers, Class C motor homes, teardrop trailers.

- Trucks: dry vans, trailers, and refrigerated trucks.

- Cabinetry: High-performance cabinet panels

- Architecture: Exterior trim, partitions, and ceilings

related Product

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.