PET Foam Core: Everything You Should Know

What is PET foam?

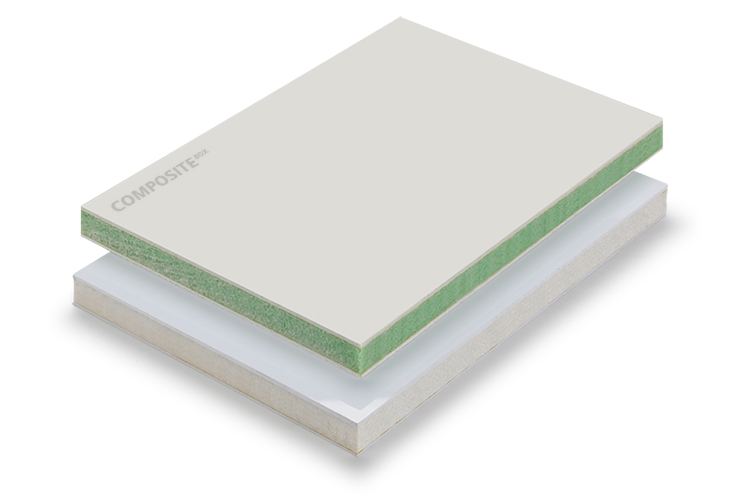

PET Foam Core is made from polyethylene terephthalate, or PET polyester resin. It is a closed-cell thermoplastic foam.

It is a high-quality core material for composite structural sandwich panels. The common density is 80–200 kg/m³. PET foam has a wide range of uses; it can be used in truck bodies, railroads, ships, automobiles, wind power, construction, and other fields.

what are the advantages of PET?

PET foam core has a lot of advantages and is a recognized foam; the following are its advantages:

100% recyclable: PET foam can be recycled and reused. Residue and chips can also be recycled, helping to protect the environment.

High Temperature Resistance: PET foam can withstand processing temperatures of up to 150 °C (302 °F) during processing. Long-term use can reach 100 °C. It is more thermally stable than EPS and less likely to deform at high temperatures.

High safety: PET foam is non-toxic. It won’t expand or explode in high heat or fire. Also, it doesn’t release toxic gases, so it is very safe.

Easy to process: PET foam is suitable for most production methods; Composite Box can be processed into PET block, PET plain board, grooving board, PET foam strip, and so on. It is stable during processing and can be adapted to different appearance structures.

Homogeneous cellular structure: The extrusion process creates fine, uniform closed-cell foam. The pore size ranges from 0.01 to 1 mm. This foam has low thermal conductivity and strong mechanical strength. Very high strength-to-density ratio.

Other advantages: good fatigue strength, chemical stability, flame retardancy, high adhesive strength, and good UV resistance.

Density range: 80, 100, 115, 135, 150, 200 kg/m³

What are the applications of PET?

Many industries can use PET.

Dry freight truck body.

- It can be used for a dry freight truck body as a sandwich core.

It is a high-quality composite material, lightweight, and UV resistant.

Wind power industry:

- Composite core

- Shells for wind turbine blades.

- Cut webs for wind turbine blades.

- Nacelle cover

Realizing the application of lightweight materials, promoting the development of new energy and new materials has long been driven by new energy.

Marine industry:

- Used for the plywood of ships’ internal structure.

- Bulkheads for ships’ cabins

- Walls

- Ceiling

- Decoration and so on.

With lightweight, corrosion resistance, and good waterproof performance.

Other uses:

Can be used as the core for building boards, furniture, etc.

Why is PET foam core better than PVC?

PET has the advantage of high performance, better heat resistance, does not release hydrogen chloride in the production process, and is 100% recyclable. PVC is easy to cause white pollution, while PET is more environmentally friendly.

PET has high tensile and compressive strength and very low water absorption (<1%).

Parameters of PET foam core

| Parameter | Typical Values | Notes |

| Physical Properties | ||

| Density | 30–150 kg/m³ | Lower density for lightweight applications; higher density for strength. |

| Water Absorption | <1% (volumetric) | Low moisture uptake ensures dimensional stability in humid environments. |

| Mechanical Properties | ||

| Tensile Strength | 30–60 MPa | High-grade variants exceed 60 MPa for structural applications. |

| Compressive Strength | 10–30 MPa | Density-dependent; higher values for load-bearing components. |

| Shear Strength | 10–20 MPa | Resists deformation under lateral forces. |

| Elastic Modulus | 1,000–3,000 MPa | Stiffness varies with density and cell structure. |

| Thermal Properties | ||

| Heat Deflection Temp. | 70–80°C (standard), up to 120°C (modified) | Maintains shape under heat; modified grades for high-temperature use. |

| Thermal Conductivity | 0.03–0.04 W/(m·K) | Good thermal insulation for energy-efficient applications. |

| Chemical Resistance | ||

| Acid/Alkali Resistance | Resistant to dilute solutions | Performance varies with chemical concentration and exposure time. |

| Solvent Resistance | Moderate resistance | Sensitive to strong solvents like acetone or benzene. |

| Other Properties | ||

| Cell Structure | Closed-cell, uniform 0.1–1 mm | Homogeneous structure ensures consistent mechanical performance. |

| Flame Retardancy | Oxygen Index 26–30% | Classified as “difficult to ignite” with UL 94 HB or V-0 ratings. |

Related Post

Related Product

Author introduction

Hello, customers

My name is Jack Yu and I am the Business Manager of Composite Box. I have been in the business of sandwich panels, refrigerated trucks and RVs for more than 10 years. Please feel free to contact us. I am happy to provide you with the best service and products.

Email: info@composite-box.com | Tel: 86+17280837525