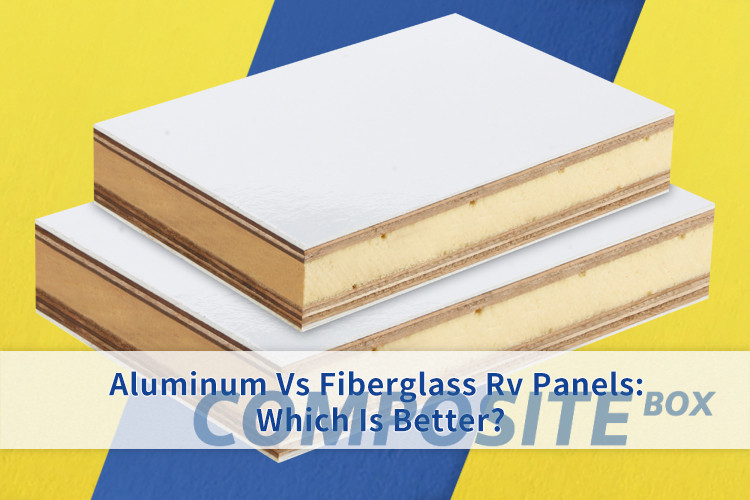

About RV Fiberglass Roof Panel Manufacturer

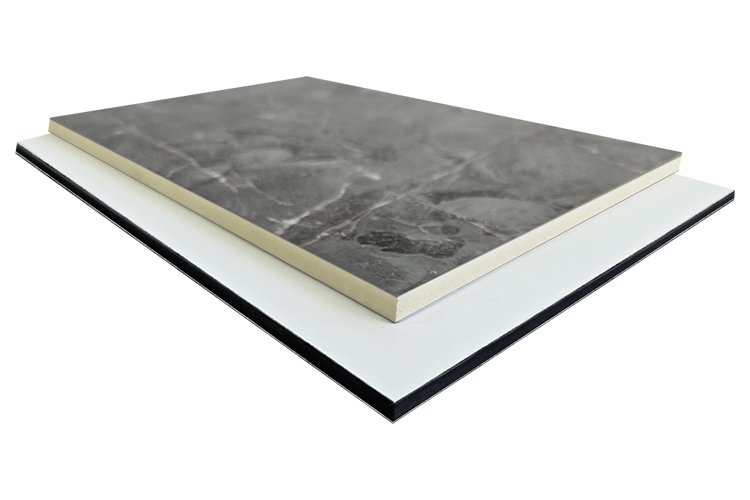

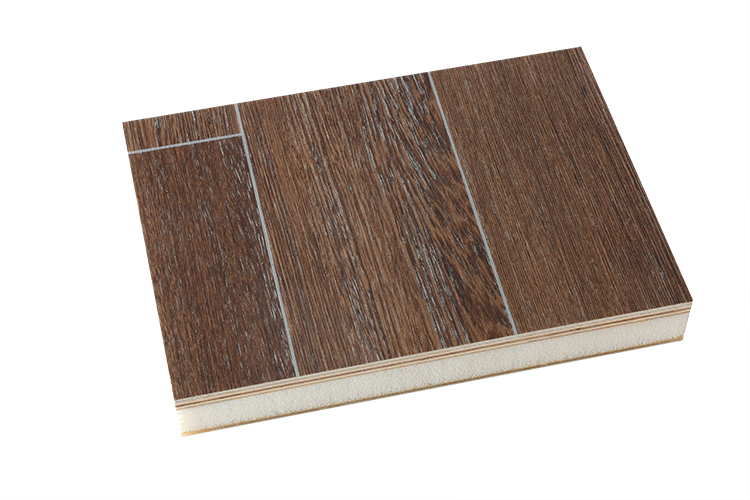

Curved roof panel made of FRP. core uses insulation foam or plywood.It is one-piece roof panel which can be curved along the radius of the sidewalls and roof joint. Good looking and seamless. Has very good waterproofing, soundproofing . And very lightweight.FRP panels for RVs are easy to clean, reduce overall vehicle weight, cost, and improve efficiency.

RV fiberglass roof customization: we can provide you with a 3D design and a customized size.

- Coating: Use waterproof gel coating; it’s easy to maintain.

- Insulation Foam: You can choose PU, XPS, PET, PVC, plywood, and other sandwich cores.

- CNC machining: provides high precision CNC grinding and cutting, etc.

- Skin: FRP or continuous fiber is provided as the skin.

- Structure: Support any kind of RV roof.

- Radius bending: We can provide a curved connection kit for connecting the side walls to the roof.

Features

We offer high quality RV roof panels. it won’t leak, has strong and tear resistant properties and we offer complete systems with kits.

Our RV roof uses high quality fiberglass and resin materials. It has a stronger appearance than aluminum foam panels, has excellent impact resistance, won’t bend or crack. And we support the development of bike kits on RV roofs. It is easy to maintain and does not require frequent maintenance. Traveling on the road is safer and less likely to shake. When it rains at night, the fiberglass roof has superior sound insulation, which means that the sound of rain is almost inaudible, allowing for a more restful sleep.

- RV FRP roofs are more durable, lasting up to 30 years!

- Less prone to breakage and dents.

- Richer and a more aesthetically pleasing exterior pattern.

- Resistant to bacteria and algae.

Get Free Quote of RV Fiberglass Roof Panel

Customized

Provide customized service for various sizes of Roof:

- CNC finishing, support for grinding and cutting, etc.

- Internal reinforcement structure, aluminum pipe, FRP pipe, etc. can be used for reinforcement.

- Reserve space for windows, doors, electrical wiring, etc.

- Water-resistant coating gel, UV-resistant treatment

Application

Provide customized service for various sizes of Roof

Towable RVs, Model C RVs, Teardrop RVs, Truck Campers, Camping Trailers, Pickup RVs and more.

Technical Parameters

| Item | Details |

| Name | Composite-box RV Fiberglass Panels For Roof |

| Materials | Fiberglass, Continuous Fibers |

| Dimensions | Standard size: 800 * 800mm, customizable; can also be produced according to the specification of 1220x2440mm or customized |

| Color | Blue, customizable |

| Resin Type | Unsaturated Polyester (UP Resin) |

| Width | 300mm – 3.2m, customizable |

| Length | Up to 12 meters, customizable |

| Transport Packaging | Pallet packaging or CKD delivery |

| Core Materials | Foam, Honeycomb panel, Plywood |

| Skin Materials | FRP or continuous fibers |

| Special Accessories | Arc – shaped connection kit for connecting side walls and roof |

| Special Treatments | Waterproof gel coating, UV – resistant treatment |

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.