High-Quality PU Insulation panel Suppliers

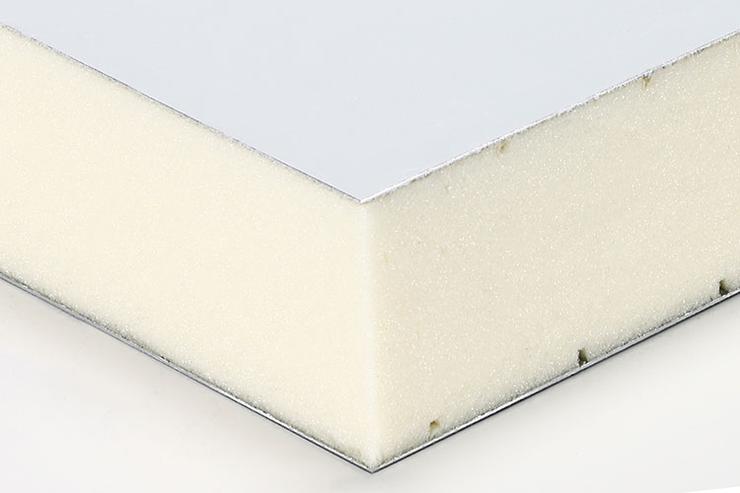

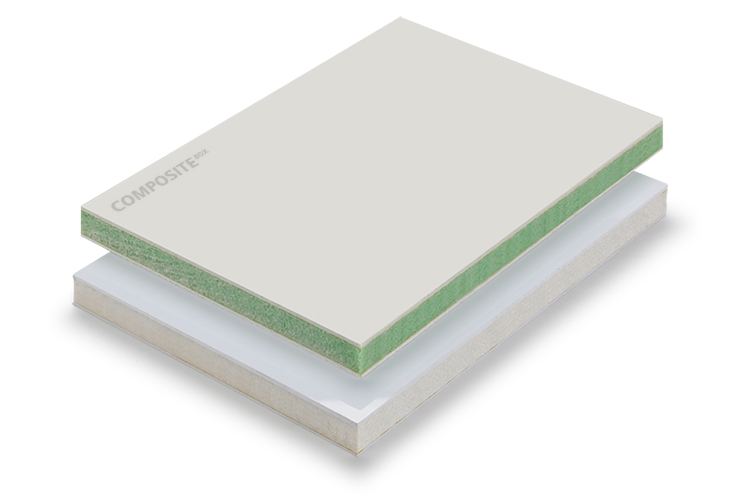

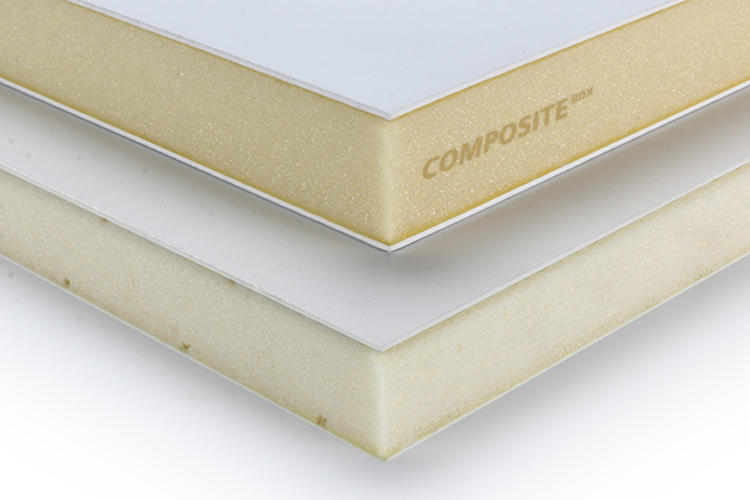

Rigid polyurethane foam panel, also known as PUR, is suitable for thermal insulation applications. It has a higher thermal insulation performance and a thermal conductivity of 0.023w/m*k. Compared with PVC, PET,XPS, and other foam core materials, it has stronger thermal insulation performance. With high-quality heat resistance and flame retardant properties, we provide the best solution.

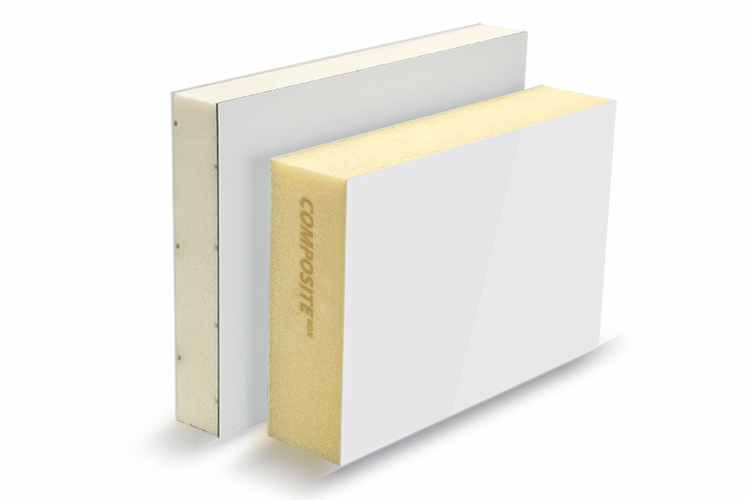

Our PU foam insulation panels are suitable for refrigerated truck bodies, cold storage, mobile panel houses, building wall panels, ceilings, marine, packaging, and other industries. They adopt a Uniform Dispersion Molding (UDM) structure with uniform injection. They are waterproof and impermeable. They are easy to install using a tongue-and-groove edge profile.

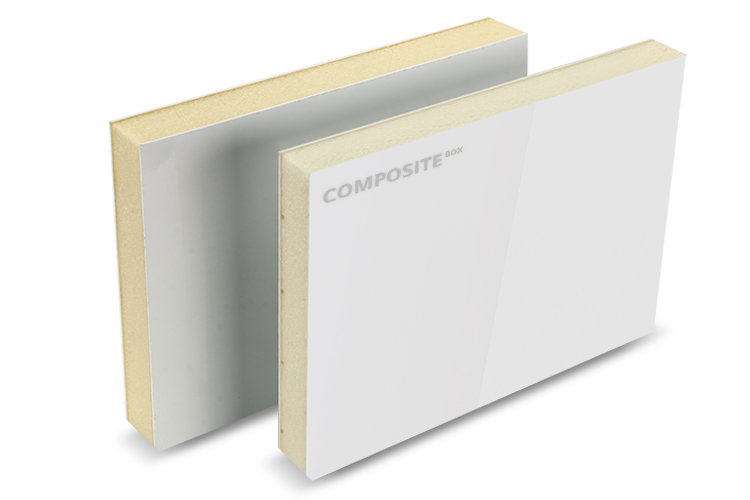

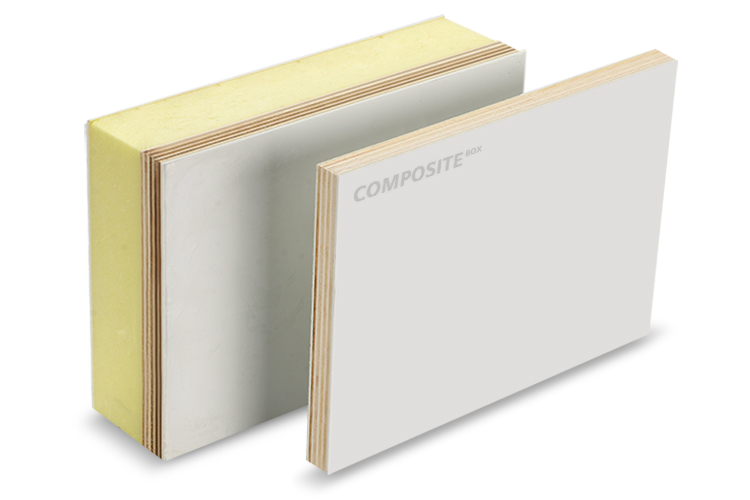

Polyurethane insulation panels can be laminated with a variety of skins, including fiberglass, continuous fiber, plywood, and color coated steel. And it is easy to process, as the closed cell structure of the foam, it is easy to sand, carve and so on. And it has good compression resistance.

Product Description

- Wide range of applications for polyurethane

- Composite European fire performance, F to B-s1

- Excellent waterproof and moistureproof performance

- Good thermal insulation performance, low thermal conductivity

- Stable chemical properties

- Resistant, long service life

- High strength, excellent impact resistance

- Good fire resistance

- Provides the highest R-value per inch

- Good abrasion resistance, high load capacity

- Withstands high temperatures up to 150 degrees Celsius

- Can withstand low temperatures of -40 degrees Celsius

Get Free Quote of High-Quality PU Insulation panel

product Catalog

contact us

Customized

- In addition to customized sizes, various accessories are also available.

- Size: We support custom-cut insulated panels.

- Edge type: Tongue and groove, rolled edge, lap panel and channel panel, etc.

- Internal reinforcement structure: FRP pipe, and steel can be added inside to make the structure stronger.

- Provide CNC finishing, and cutting. Grinding etc.

- Thickness 20~150mm

- Length: customized width max 12m

- Width: customized up to 3.6m

- Panel skin: fibreglass, new fibreglass, stainless steel

- Colour: Beige

Application of PU/PUR insulated panels

Polyurethane insulated panels can be used for cold storage, thermal insulation, construction, warehousing and other purposes.

Related Product

fiberglass PU/PUR Insulation panel

Fiberglass polyurethane insulation panel is one of the very popular insulated sandwich panel materials.

Continuous fiber insulation panel

Continuous fiber has better toughness and resilience, not easy to crack, more resilient foam insulation sandwich panels

Technical Parameters

| item | content |

|---|---|

| Core Material Density | 40 kg/m³ |

| Thickness Range | 20 – 140 mm |

| Steel Plate Thickness | 0.3 – 1.0 mm |

| Standard Length | Up to 12 meters |

| Panel Thickness | 50mm, 60mm, 75mm, 100mm (Customizable) |

| Thermal Conductivity of Core Material | 0.022 W/mK |

| Sound Insulation | 30 dB |

| Thermal Conductivity of Polyurethane Sandwich Panel (Mentioned Elsewhere) | 0.023 w/(m•k) |

FAQ

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.