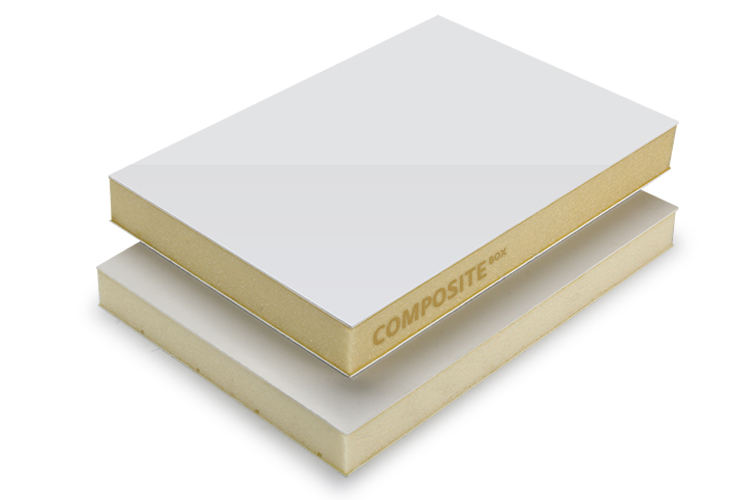

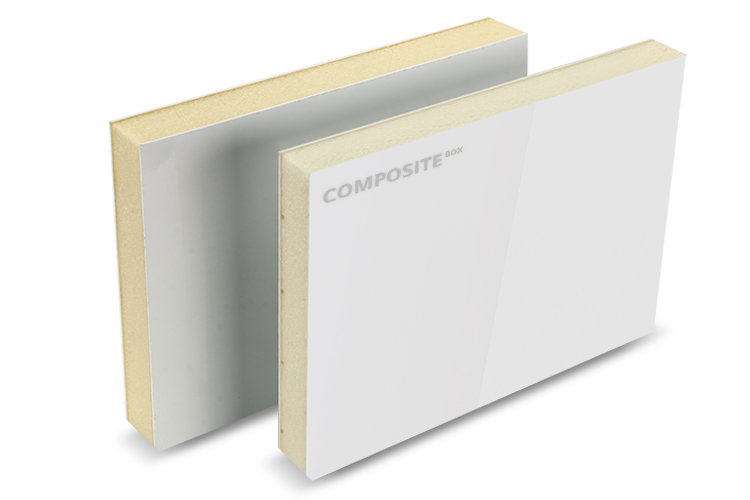

150mm Insulated Polyurethane Sandwich Panel

150mm polyurethane sandwich panels can be used for manufacturing shipping containers, insulated refrigerated wall panels, and refrigerated trucks. The outer skin utilizes pre-coated galvanized steel sheets, color-coated steel sheets, or fiberglass panels (GRP/FRP sheets). The core material consists of rigid polyurethane foam with a density of 41–46 kg/m³. Custom widths and dimensions are available.

Features

Composite Box offers high-strength rigid polyurethane foam composite panels, serving as premium insulated sandwich panels. Featuring a 150mm thick high-density core material, it delivers low thermal conductivity and exceptional insulation performance, enhancing indoor comfort while significantly reducing energy consumption for cooling or heating equipment. Widely applicable in scenarios demanding extreme thermal insulation, such as building envelopes and refrigerated vehicle manufacturing.

- Highly Energy-Efficient: Long-term low thermal conductivity significantly reduces operational energy consumption

- Exceptional Durability: Requires minimal maintenance with a service life exceeding 15 years

- Flexible Customization: Supports custom dimensions. Multiple skins and surface finishes available for customization

Get Free Quote of 150mm Insulated Polyurethane Sandwich Panel

Related Products

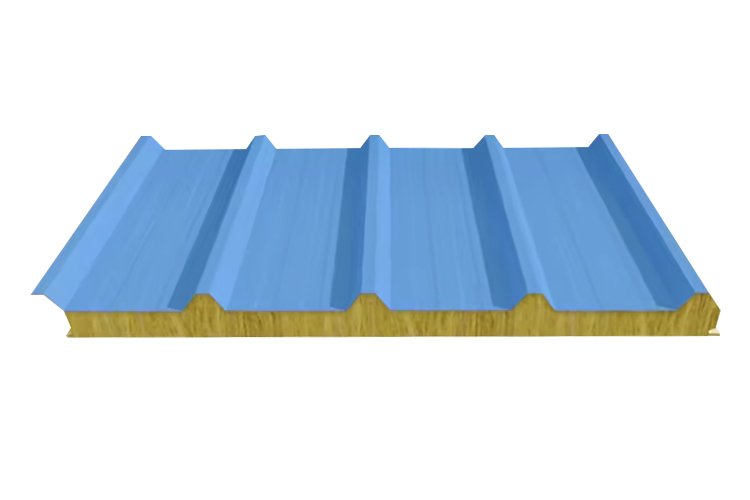

Polyurethane Sandwich Panels with Color-Coated Steel Facing

Features two layers of color-coated steel sheets with rigid polyurethane foam core. The color-coated steel sheets can be customized to RAL colors, enhancing the aesthetics of buildings and temporary housing.

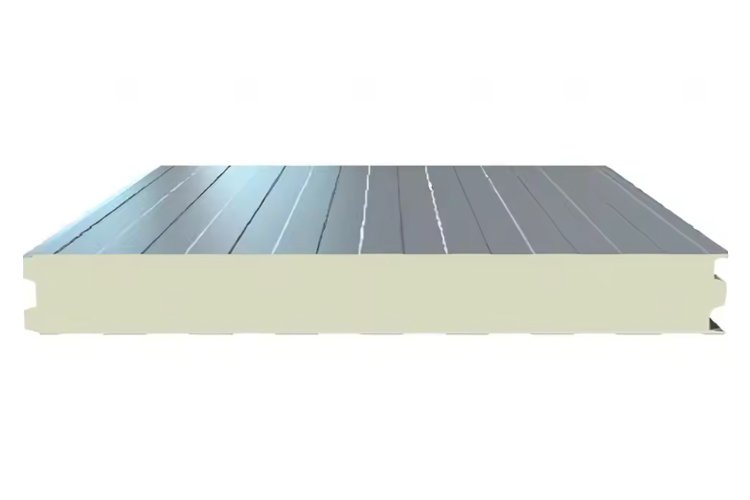

Pre-coated Galvanized Steel Polyurethane Sandwich Panel

Features pre-coated galvanized steel as surface material, combining rust resistance with an attractive finish. Ideal for high-strength enclosure projects like clean rooms and cold storage facilities. 150mm thickness delivers reliable thermal insulation.

Glass-Reinforced Polyester (GRP) Polyurethane Sandwich Panels

The 150mm GRP polyurethane sandwich panel is lightweight, durable, and impact-resistant. It is suitable for refrigerated vehicles and building partitions, ideal for complex environments and applications requiring high thermal insulation.

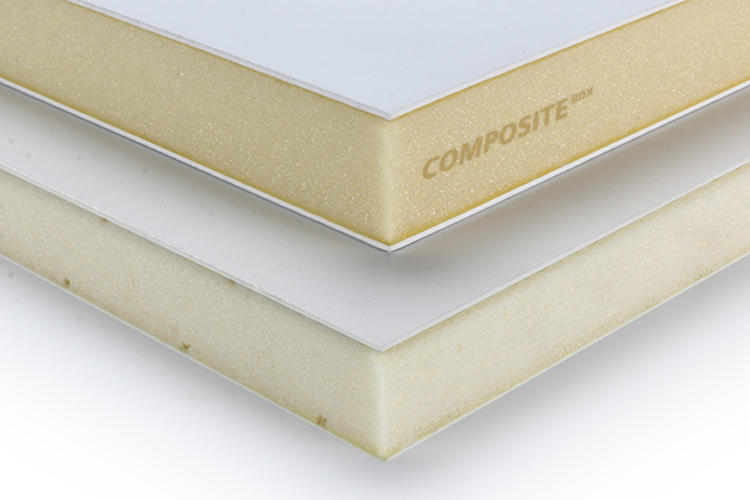

Structure of fiberglass PU

PU foam

PU foam is a synthetic plastic with a closed-cell structure that has very high thermal insulation properties. It is widely used in thermal insulation applications. The thermal conductivity is 0.18~0.25W/mk.

FRP fiberglass sheet

FRP is a high-performance material with good physical properties and consists of glass fiber reinforcement. It possesses high performance, high compression resistance, and UV resistance.

Product Specifications

Commonly used for refrigeration, warming, freezer applications.

product parameters

| Parameter | Specification |

|---|---|

| Product Name | 150mm Polyurethane Foam Sandwich Panel |

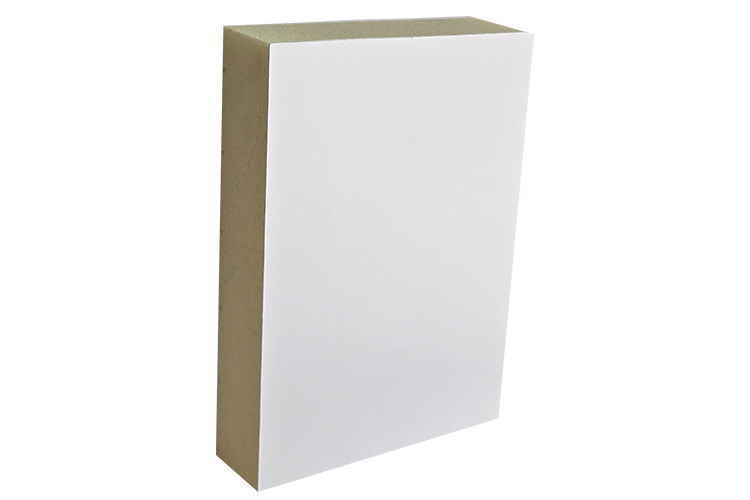

| Thickness | 150mm |

| Core Density | 41-46 kg/m³ |

| Color | Black, White, Gray, Blue, etc. |

| Fire Rating | Class B1 (GB 8624-2012) |

| Panel Material | Color-coated steel sheet/Pre-coated galvanized sheet/Fiberglass board |

| Thermal Conductivity | ≤0.022 W/(m·K) |

| Standard Width | 1000mm, 1150mm, 1200mm (Customizable) |

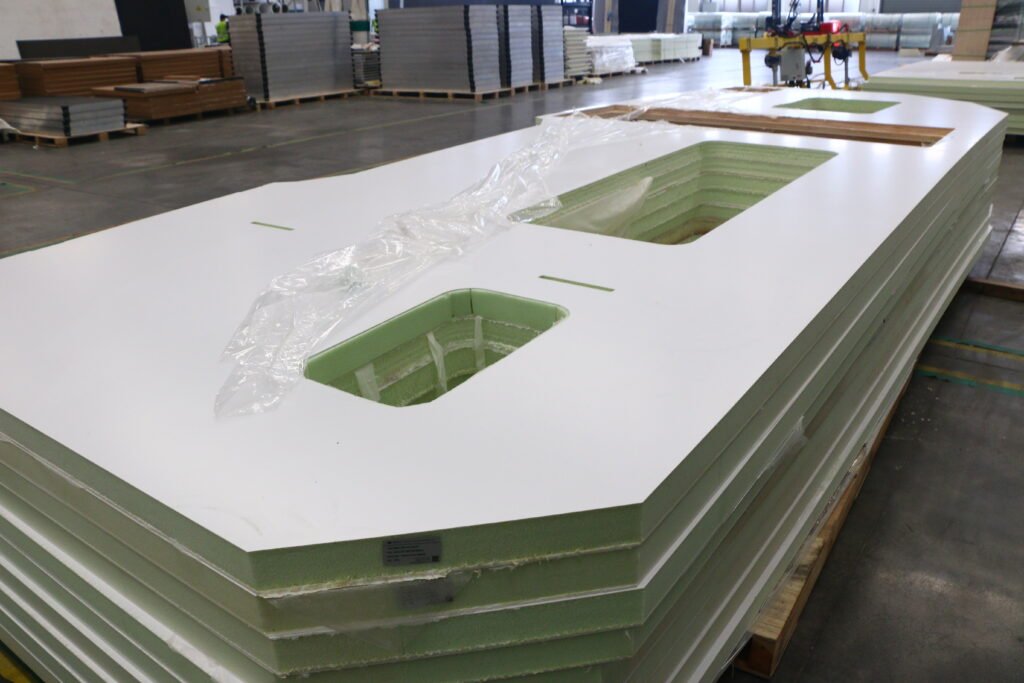

Custom Processing

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.