Vegetable and Fruit Refrigerated Truck Bodies Solution

Refrigerated Truck bodies specially designed for transporting vegetables and fruits, from 3.2m to 11.8m, are made of polyurethane/XPS insulation material, with low thermal conductivity, which effectively extends the shelf-life and prevents rotting to ensure that they arrive at their destination fresh. Arrival at the destination.

We use modular body design, it is as simple as building blocks. Rigid foam insulation enables precise temperature control, while we optimize sealing to prevent moisture loss. We can design bodies to fit the chassis of a truck, provide professional design services and manufacture high-quality products. Better transportation of vegetables and fruits.

Features

Vegetable and fruit refrigerated truck bodies use fiberglass skin, thermal insulation foam, and quick assembly design. With easy-to-clean aluminium alloy floor, easy to clean and reduce mildew, customizable shelves, provide E-track, rear door side door, tail lift, LED lights, and plant growth lighting. Our design team offers a wide range of customization options:

Material construction: vegetables and fruits are fragile and easily damaged, fiberglass material has waterproof and impact-resistant properties

Excellent temperature control: use insulation foam with a thickness of 10~50mm to reduce temperature fluctuation

Models: we are well-versed in every brand of truck chassis.

Get Free Quote of Vegetable and Fruit Refrigerated Truck Bodies

Description

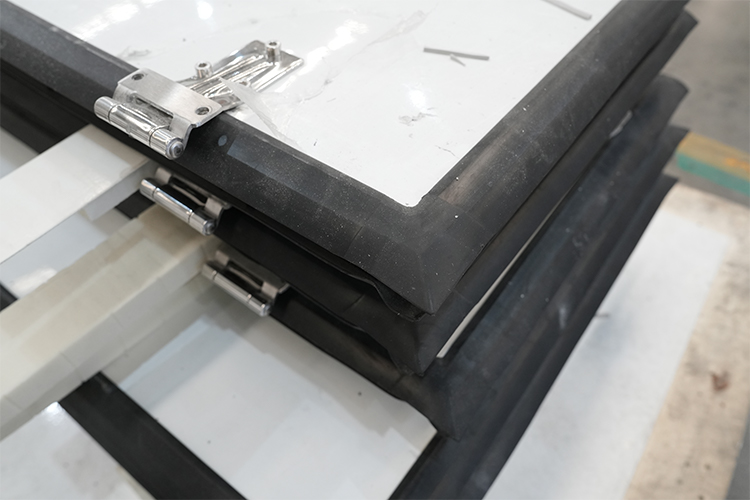

Rigid Insulated Partitions are superior in structural stability, impact resistance, and durability. They use XPS foam board and fiberglass-reinforced plastic. The frames are made of fibreglass or aluminium. This design helps them stay strong and not deform over time. The sealing uses special rubber strips. These strips offer better thermal insulation and lower energy use. They are perfect for refrigerated trucks in multi-temperature zones. Flexible partitions are adaptable, but they are not as strong in pressure resistance and durability. On the other hand, rigid insulated partitions perform well too. They ensure safety and protection during long-distance cold chain transport.

Fruit & Vegetable Cold Chain Solutions

By choosing us, you can transport almost any fruit and vegetable. If you choose to customize a multi-temperature zone wagon, you can transport many different temperature controlled products at the same time. For example, melons, leafy vegetables, berries, tropical fruits, etc., which require different temperatures for transportation. Our refrigerated wagons can be pre-cooled quickly before departure from the country of origin, reducing pre-cooling time and fuel consumption.

Advantages

- Efficient cold chain

- Environmentally friendly

- Durable

- Hygienic

- Suitable for fruits and vegetables

Application

Application of Refrigerated Food Truck Body

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.