Refrigerated Pantech Body

Composite Box offers a complete refrigerated Pantech body solution, supporting dry, refrigerated, and insulated transport. Featuring fiberglass polyurethane sandwich panels, it facilitates transportation and rapid assembly. Widely used for enclosed truck bodies, it is the optimal choice for Pantech trucks in Australia and New Zealand.

Features

The Pantech refrigerated body offers a premium temperature-controlled transport solution, specifically suited for regions like Australia and New Zealand. Designed for high-temperature and high-UV environments, it provides optimal assurance for cold chain logistics and food distribution. Featuring a sandwich composite panel structure, it incorporates a high-strength 1.2mm fiberglass outer layer with a high-density rigid polyurethane foam core.

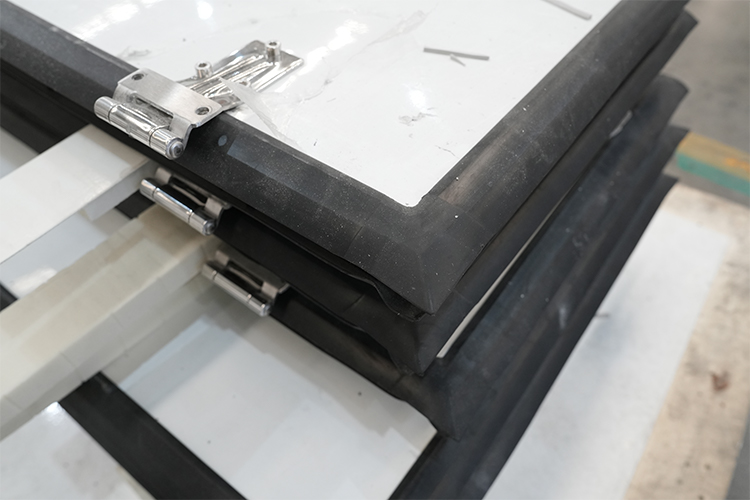

Manufactured using CKD/SKD methods, it significantly streamlines transportation processes, reduces shipping costs, and shortens on-site assembly time. The body is easy to maintain and clean. The composite door frame provides excellent sealing performance, equipped with double-layer gaskets and heavy-duty hinges. Utilizes 80-100mm composite panels. Features include a stainless steel door lock system, collision guards, aluminum profile frames, and drainage systems. Ensures superior thermal insulation. Composite Box delivers the optimal solution.

Get Free Quote of Pantech bodies

What are Pantech bodies?

Pantech Bodies are enclosed truck bodies widely used in the transportation industry, with the name derived from “Panel Technology.” These bodies typically feature a composite panel structure, offering high strength, lightweight properties, and durability. Pantech bodies are particularly well-suited for conversion into refrigerated, explosion-proof, or specialized cargo vehicles. Their modular design facilitates production, transportation, and assembly, making them one of the mainstream choices for commercial freight vehicles.

Specifications

| Parameter Category | Specific Specifications |

|---|---|

| External Dimensions | 6700mm (L) × 2450mm (W) × 2600mm (H) |

| Internal Dimensions | 6550mm (L) × 2300mm (W) × 2400mm (H) |

| Panel Thickness | 80mm standard (optional 100mm thickened) |

| Total Volume | Approximately 36.2 cubic meters |

| Empty Body Weight | Approx. 950–1100 kg (depending on configuration) |

| Maximum Payload | 4000–4500 kg |

| Temperature Range | -25°C to +12°C (depending on refrigeration unit) |

| Door Opening | Rear door: 2200mm (H) × 2300mm (W); side door optional |

| Floor Load Capacity | 1500 kg/m² uniformly distributed load |

Pantech Body Configuration List

- Fiberglass polyurethane composite panels, including roof, side, floor, and front panels.

- Aluminum profile frame components

- Corner pieces and connectors

- Rear double doors (fiberglass panels)

- Stainless steel door locks and hinge system

- Double-layer sealing gaskets

- Door bars and bumper rails

- Refrigeration unit mounting frame

- Electrical conduit interfaces

- E-track

- Ventilation openings

Custom Pantech Bodies

Composite Box offers fully customizable Pantech bodies to meet specialized requirements across industries. We tailor length, width, and height to vehicle chassis specifications. Optimized weight design enhances cargo capacity. Multi-temperature zone configurations enable simultaneous transport of temperature-sensitive goods with independent climate control systems.

Additionally, we develop specialized solutions for unique cargo requirements, such as pharmaceutical transport bodies. For hazardous materials transport, we incorporate anti-static features and reinforced flooring.

We customize materials across the board. Exterior panels are available in colored gel-coated finishes, aluminum alloy, and stainless steel. Insulated polyurethane panels reach up to 150mm thickness. We ensure every Pantech body achieves optimal quality and functionality.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.