Fiberglass Refrigerated Box For Pickup Truck Manufacturer

Best refrigerated & reefer box for pickup

Refrigerated pickup truck box use fiberglass foam panels to insulate and thermally insulate the vehicle, also known as refrigerated light box truck body. Uses an insulated foam core. Suitable for transportation of daily fresh and meat logistics. Suitable for cold chain companies and supermarket chains for distribution.

It can keep the temperature control of -18℃~7℃. And long service life, low thermal conductivity, lightweight, can maintain efficient transportation and fuel performance.

Features:

- Size: customizable 3~6m length, high speed 1.7~2.7m

- Loading capacity: 10~30m³

- Material: fiberglass XPS sandwich panel/PU sandwich panel

- Provide 15 kinds of refrigerated pickup box kits

Features

Composite Box is a manufacturer specializing in refrigerated and dry cargo truck bodies, we integrate production, sales, research, and development, we provide full-chain solutions, and link all departments together to provide you with responsive service. We are able to offer low-cost, high-quality, and high-return refrigerated truck bodies. We specialize in serving logistics companies, supermarket chains, leasing companies, and large cold chain companies.

The refrigerated pickup truck boxes use the most advanced design and materials to replace the earlier aluminum/steel pickup truck box body, which makes the insulation performance more excellent and improves the service life. The use of FRP allows for excellent impact resistance and anti-deformation features. If you have been using aluminum bodies before this, you will find that it is especially easy to produce bumpy cracks, which makes the appearance unsightly, and easy to leak air, which ultimately leads to reduced heat preservation performance. That’s why we’ve addressed these pain points to develop our fiberglass pickup box body.

We have a professional truck design team that has been working in this industry for more than 20 years, and we visit and study in many countries from time to time. To ensure that we can always produce high standard and high quality insulated pickup truck bodies.In addition, we provide a wide range of accessories to choose from in order to facilitate the assembly of the main body for our customers.

- Professional auto body design team, customized solutions for you

- The most advanced high-performance composite materials, replacing traditional aluminum, steel, solid wood, etc.

- The most advanced manufacturing equipment, imported from the EU, Japan, the United States, and other countries

- Provide CKD delivery, so that the assembly is as simple as “building blocks”, to realize rapid assembly.

Get Free Quote of Fiberglass Refrigerated Box For Pickup Truck

product Catalog

contact us

advantages

The refrigerated pickup box body uses a 20~60mm sheet, the thickness is decided according to the actual use area.

Adopt a fashionable appearance design, no rivets design, make the appearance more beautiful, establish the corporate image, and make consumers more desirable to our products.

With the use of modular components, assembly is easier and more convenient, 2 people only need 3 hours to complete the assembly.

We provide refrigeration unit equipment and support multi-temperature zones, which can satisfy freezing, refrigerating, and normal temperature zones at the same time. The space can be reasonably planned.

Reinforced with steel structure to make the vehicle less shaking and more stable during driving, especially on the highway.

- Lightweight, 30% weight reduction

- 10% increase in high-load capacity

- Aerodynamic, 8% higher acceleration

- The long service life of up to 30 years

High-performance materials

High-performance thermoset fiberglass:

Using fiberglass as the skin is very durable, not easy to scratch, wear-resistant, and not easy to produce bumpy scars. In addition to this, new continuous fiber materials can be chosen to replace fiberglass.

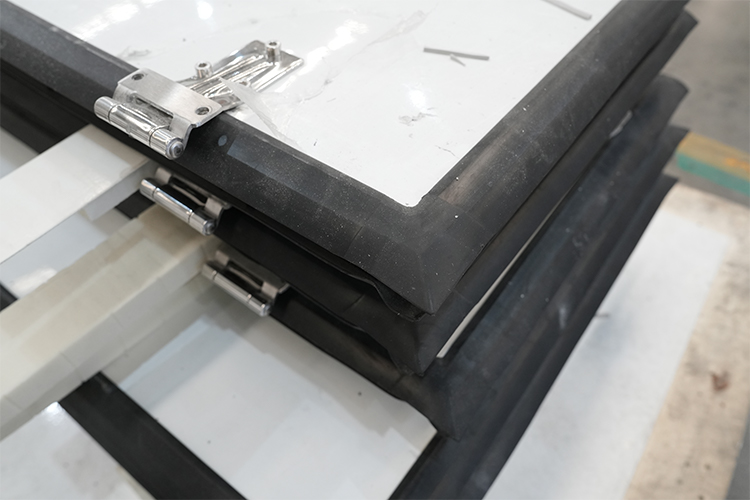

Material surface treatment:

In order to make better sealing performance and waterproof performance, we use a steel structure frame at the joints of the panels and seal them perfectly, and the surface of the FRP panels is waterproofed with a gelatin layer

Core material:

The material can be chosen from a wide range of foams, whether it is XPS foam, polyurethane foam, or PVC foam, all of them can realize perfect thermal insulation effect, and they have different performance in thermal insulation, heat insulation, and corrosion resistance.

| Material Name | Features |

| XPS Foam FRP Sandwich Panels | High moisture resistance, stable thermal performance, maintains constant temperature throughout the year, durable, anti-aging properties. |

| PU Foam FRP Sandwich Panels | Excellent heat insulation, significantly reduces energy consumption, lightweight, easy to install, stable structure resistant to external impacts. |

| PVC Foam FRP Sandwich Panels | High strength, resistant to extrusion, waterproof, corrosion-resistant, stable dimensions with no deformation, suitable for harsh environments. |

Customize your refrigerated pickup truck box

We support many kinds of customization

The floor is made of non-slip flooring and T-shaped aluminum duct flooring. Others offer stainless steel door frames, hinges, impact rubber blocks, refrigeration units, bumpers, LED spotlights, E-track, skirting boards, roll-up doors, chassis frames, pallets, etc.

Provide CNC cutting service, sheet metal processing, laser welding, aluminum extrusion profiles, etc.

Application

Application

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.