Aluminum Foam Sandwich Panel

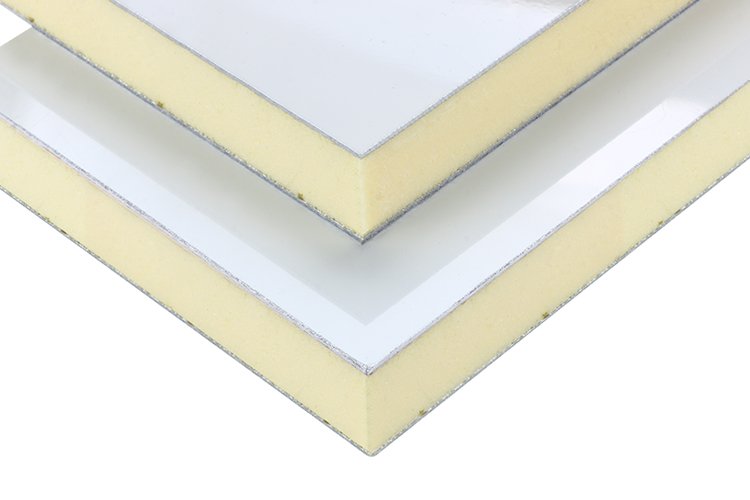

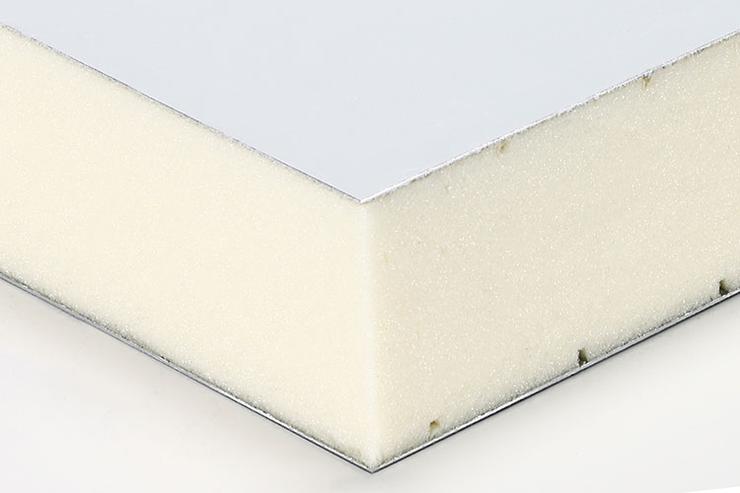

Aluminum foam core sandwich panel is also called ACP foam panel. It consists of three layers of structure, two layers of aluminum panels at the top and bottom, and one layer of foam core. Similar to aluminiowy panel o strukturze plastra miodu, ACP foam panels offer high strength, rust resistance, and corrosion protection, good decorative effect, heat insulation, sound absorption, are very durable, and have strong impact resistance. We are a professional ACP sandwich panel supplier and manufacturer.

Aluminum foam core panels are widely used in exterior wall panels, marine applications, refrigerated trucks, mobile homes, cold storage, exterior wall finishes, and other applications.

We are the most professional XPS sandwich panel manufacturer in China. We offer OEM production with customized sizes and skins, CNC machining services.

- Panel length: 2440 mm, 3200 mm, etc.

- Panel width: 1000 mm, 1220 mm, 1500 mm, etc.

- Thickness of aluminum skin: 0.5–2 mm

- foam core: PU, XPS, PET, PVC, EPS, PP honeycomb

- Klej: environmentally friendly polyurethane adhesive to prevent deglossing and cracking.

Cechy

ACP Aluminum Foam sandwich panels are used as a common industrial manufactured product for construction, automotive, and decorative materials. They can have exquisite finishes and colors. They are corrosion-resistant, lightweight, and high strength. They can be fireproof, waterproof, and moistureproof. They are of great significance for buildings. And used in dry trucks, refrigerated trucks, and mobile homes, and can have strong impact resistance.

Charakterystyka:

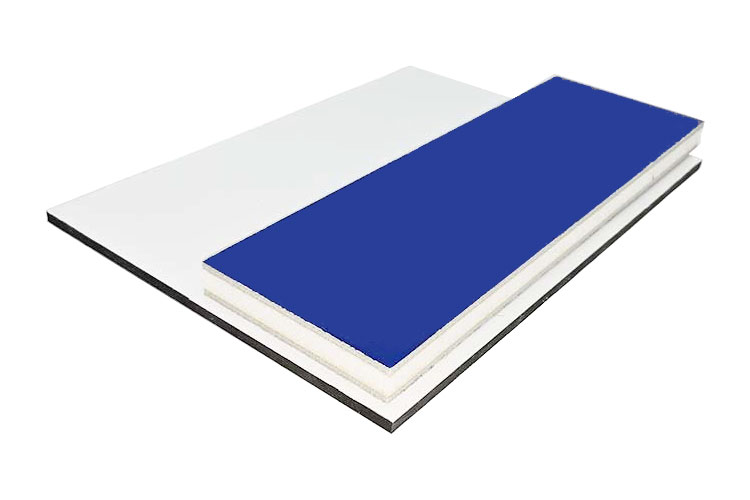

- Estetyka: Aluminum foam sandwich panels can be customized with a wide range of colors, finishes, aqnd patterns.

- Use high quality color map aluminum sheet (3003,5083,5052 etc.)

- Layer: PVDF layer, PE layer.

- Wysoka wytrzymałość: ACP foam panels are high-strength materials; the aluminum structure can withstand huge impacts.

- Easy to process: It can be processed by a CNC machine, is easy to cut and very convenient.

- Fireproof: It has fireproof performance, and the melting point reaches 600℃.

- Flat: ACP will not bend and deform, unlike plywood, which is easily deformed.

- Lekka waga: ACP foam panels are lightweight, with 40kgs/m³ of foam. They can be used in box trucks to reduce weight.

- Izolacja termiczna: Core uses thermal insulation foam, which has the functions of thermal insulation and heat preservation, with a thermal conductivity of 0.03 W/m·K.

- Trwałość: metal skin is very strong and durable, not easy to age.

Surface color:

- Solid color series: according to RAL series colors

- Customized metallic color, imitation wood grain series, stone grain.

Uzyskaj bezpłatną wycenę Aluminum Foam Sandwich Panel

Powiązany produkt

XPS Foam Aluminum Sandwich Panel

Uses XPS closed-cell extruded polystyrene foam. It has thermal insulation and non-absorbent properties, and can be used for waterproof and thermal insulation applications when combined with a pre-painted aluminum skin.

PU foam aluminum sandwich panel

Using polyurethane foam with a density of 28~48 kg/m³, it is very lightweight. These sandwich panels have strong thermal insulation properties and are suitable for use in areas with high strength and high requirements for thermal insulation.

PET Foam Aluminum Sandwich Panel

Using 100% recyclable PET foam, also known as polyethylene terephthalate foam, with a density re 60~280kg/m³. It has high strength performance, excellent high compression resistance of PET, and very low water absorption, the same as XPS.

PVC foam sandwich panels

Closed cell PVC rigid foam, density: 38-240 kg/m³. It has good insulating properties and has a honeycomb structure, and is excellent in waterproofing and strength. It is easy to process and is a high-quality sandwich layer material.

styrofoam aluminum panels

Also known as aluminum alloy polystyrene sandwich panels, these offer lightweight construction with high strength and a Class B1 fire rating. They are suitable for use in various harsh environments.

Surface Treatment of Aluminum Alloy Skins

The aluminum surface of our sandwich panels can be processed into various texture effects through multiple techniques. Common texture processing methods primarily include the following, offering a perfect custom experience.

Brushed: Fine straight lines, soft matte elegance.

Mirror: High polish, strong reflection, modern luxury.

Embossed: Rolled 3D patterns (diamond, square), non-slip decor.

Sandblasted: Uniform matte grains, vintage low-key feel

Wood/Stone: Printed realistic wood or marble look

Diamond: Pyramid bumps, multi-angle sparkle, super grip

Aluminum Alloy Surface Coating Color Customization

Aluminum alloy surface colors can be customized according to RAL or Pantone color charts. We provide various processes including fluorocarbon spraying, powder coating, and anodizing. The colors are firm, long-lasting, and resistant to fading. Surfaces can be finished in matte, glossy, or metallic textures.

Composite Box 100% meets diverse needs for building curtain walls, door/window profiles, interior decoration, etc. Simply provide the color code or sample, and we will quickly match the color and send a sample for confirmation. We offer extensive OEM customization services.

Shapes of foam aluminum sandwich panels

- Open edges

- Closed edges

- Prefabricated panels

parametry

| Opis | Opcje |

| Nazwa produktu | ACP Aluminum Foam Core Sandwich Panel |

| Design Style | Solid color, brick pattern, stone pattern, wood pattern or customized |

| Surface Material | Aluminum skin |

| Materiał rdzenia | PUF (polyurethane foam), XPS (extruded polystyrene foam), EPS, rock wool, rigid polyurethane foam (depending on specific product) |

| Coating Surface | High temperature resistant automotive paint, PVDF, PE, anodized, glossy, etc. |

| Kolor | As required by customer (polished, metallic color, solid color, wood color, stone color, anodized color, etc.) |

| Grubość | 10mm – 140mm |

| Długość | 2440mm, 3200mm, 3800mm, 4880mm, 5800mm (customizable length) or as per customer’s choice (depending on specific product) |

| Certificate | ISO9001 |

| Effective Width | 383mm, 1000mm, 1220mm, 1500mm or as required |

| Aluminum Skin Thickness | 0.5mm – 2mm or as required |

| Aluminum Alloy | 1100, 3003, 5005 |

| Adhesive | Klej poliuretanowy |

| Coating Type | Polyvinylidene fluoride, polytetrafluoroethylene, polyethylene |

| Shape | Flat panel, curved panel, custom shape as per drawing |

| Panel Edge | Standard open edge, closed edge, custom edge with embedded aluminum extrusion |

| Produkcja | Provide drawing-based manufacturing or cutting services as required |

| Klasa odporności ogniowej | B1 level |

| Zalety | Fireproof, waterproof, heat-insulating, sound-insulating, shockproof, environmentally friendly, flame-retardant, easy to install. |

Application of ACP/aluminum Foam Sandwich Panel

It can be used in the construction industry, automotive industry, insulation and refrigeration applications.

Construction: external cladding, building facades, decoration, partitions, doors

cold rooms, internal partitions.

refrigerated truck bodies, trailers

Hotel villas, office buildings, hospitals, schools

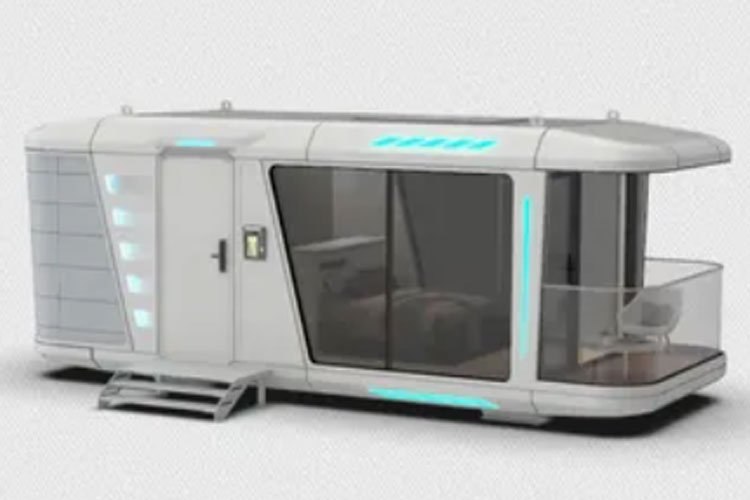

Containerized houses, modular houses, prefabricated houses

vessel

Przetwarzanie niestandardowe

Osadzone konstrukcje wzmacniające

Aby zwiększyć wytrzymałość i funkcjonalność, w panelach kompozytowych można osadzić materiały wzmacniające. Dostępne opcje obejmują sklejkę, profile ze stopu aluminium, rury GRP, stalowe elementy konstrukcyjne i inne.

Przetwarzanie kompozytów wielomateriałowych

Specjalizujemy się w przetwarzaniu materiałów kompozytowych, takich jak FRP, CFRT i rdzenie piankowe, zapewniając doskonałą wydajność przy jednoczesnym spełnieniu różnorodnych wymagań aplikacji.

Precyzyjna obróbka CNC

Zaawansowane centra obróbcze CNC umożliwiają precyzyjne cięcie z dużą prędkością, frezowanie złożonych konturów, wiercenie i nie tylko.

Przetwarzanie krawędziowe

Wykończenie krawędzi i integracja złączy są wykonywane zgodnie z określonymi wymaganiami. Usługi obejmują oklejanie krawędzi, fazowanie i szlifowanie, impregnację wodoodporną i osadzanie nakrętek.

Dlaczego warto nas wybrać?

Zadowolenie klienta

Naleganie na wysokiej jakości produkty i serwery, skoncentrowane na doświadczeniu klienta.

Zapewnienie jakości

Ściśle kontrolujemy każdy proces produkcyjny, aby zapewnić naszym klientom niezawodną jakość.

Zaawansowana linia produkcyjna

Najlepsza na świecie linia produkcyjna zapewnia precyzję i wydajność produktu.

Personalizacja

Zapewniamy dostosowanie 100%, dzięki czemu zamówienia są mniej trudne.