Marine Fiberglass Composite Panels

Composite Box marine fiberglass composite panels are specifically designed for marine vessel applications. They offer outstanding corrosion resistance and strong acid resistance. Capable of achieving stringent waterproof performance, they are highly suitable for use in hulls, plywood, or decorative applications. With a long service life, they represent an ideal marine material.

- Excellent corrosion resistance

- High strength-to-weight ratio

- Easy to machine and drill

- Wide range of applications

We offer specifications for all thicknesses and sizes, large production volumes and reduced costs.

Features

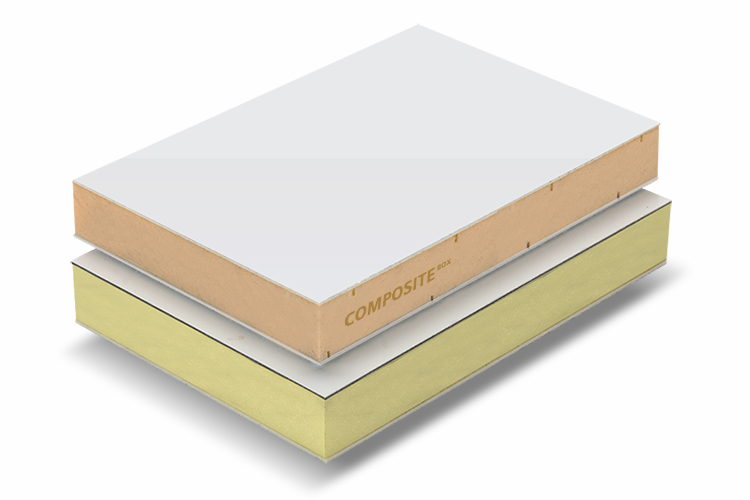

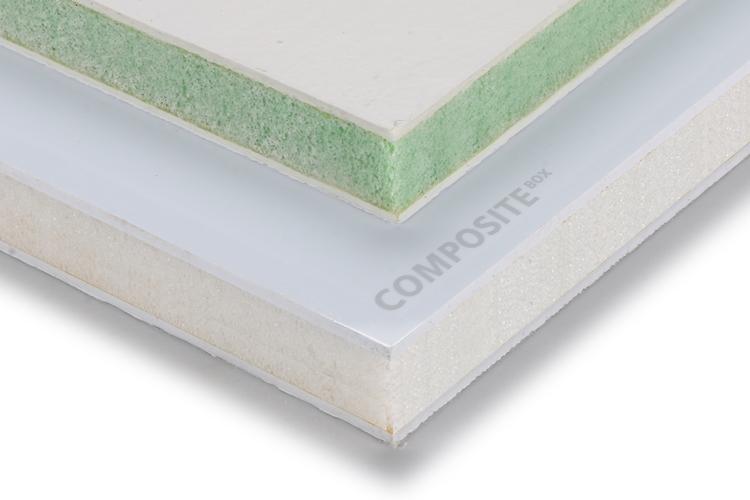

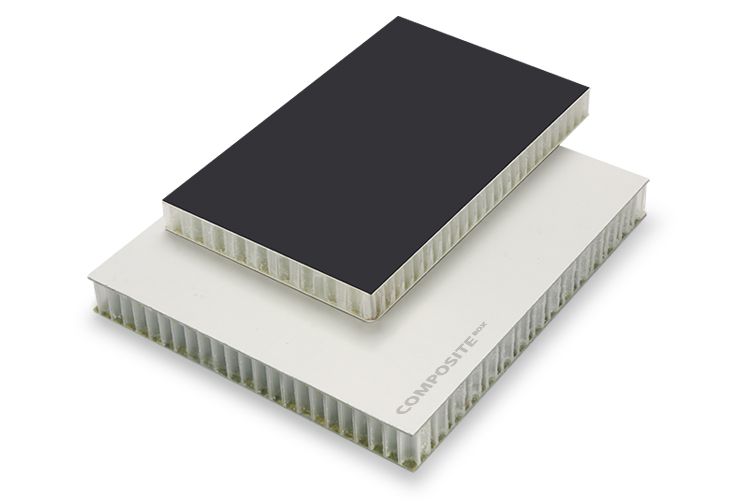

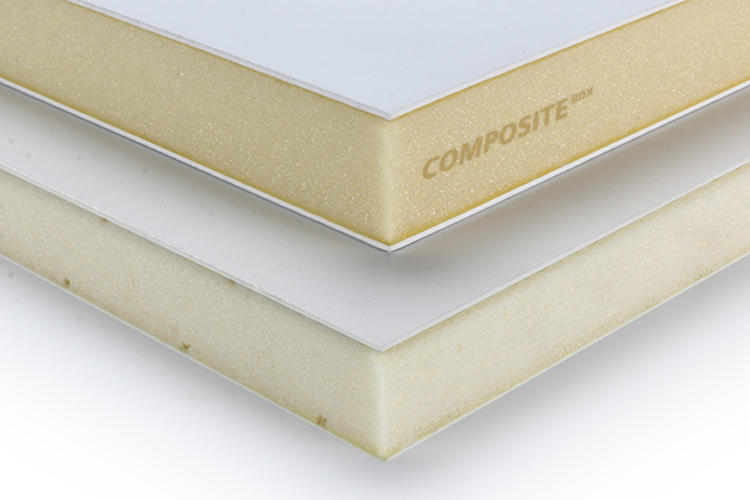

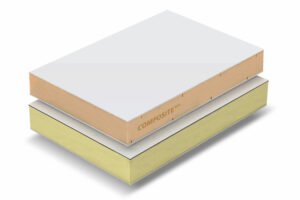

Composite Box marine fiberglass composite panels utilize FRP facings or continuous fiber (CFRT). Core materials can be selected from plywood or high-density closed-cell XPS foam, manufactured through a composite process. Core materials can be chosen according to the specific requirements of different ship sections. This not only achieves lightweight construction but also completely resolves the issues of rot, deformation, and mold growth common in traditional materials.

Our marine composite panels are approximately 50% lighter than traditional marine boards, reducing vessel deadweight to enhance fuel efficiency and cargo capacity. They also offer excellent secondary processing capabilities, simplifying applications such as adding anti-slip treatments or achieving aesthetic finishes.

Supporting CNC cutting, milling, and drilling, they can be customized to meet marine material standards. Suitable for ship interlayers, decks, bulkheads, interior panels, and internal furnishings, Composite Box sandwich panels deliver superior marine material solutions.

Get Free Quote of Marine Fiberglass Composite Panels

application of marine FRP composite

Our marine fiberglass composite panels can be used in various locations. We possess extensive design and application experience with diverse materials, and our product range includes:

- Hulls and external skins for main hulls and superstructures.

- Work decks, walkways, and anti-slip surfaces for all types of vessels.

- Internal structures and finishes within the hull, including bulkheads, partitions, and ceilings.

- Marine components such as door and window frames, fairings, and ventilation ducts.

- Flybridge structures, helm stations, interior paneling, and furniture substrates for yachts.

Feature Description

- Exceptional corrosion resistance, withstanding seawater salt spray and chemical erosion.

- Fully waterproof and sealed, ensuring interior dryness.

- High strength-to-weight ratio, lightweight yet robust for enhanced efficiency.

- Superior weather resistance, UV-resistant and resistant to aging.

- Easy to process and install, with a smooth surface and excellent decorative properties.

Specifications

| Item | Specification Details | Notes / Customizable Options |

|---|---|---|

| Material | Glass-fiber reinforced composite (GRP) | Fiberglass reinforced plastic composite |

| Coating | Optional gel coat finish | Smooth, UV-resistant, corrosion-resistant gel coat |

| Density | Approx. 32–60 kg/m³ (adjustable upon request) | Core density adjustable for lightweight needs |

| Standard Thicknesses | 3mm, 5mm, 8mm, 10mm, 12mm, 15mm, 20mm | Total panel thickness; thicker options (up to 150mm) available on request |

| Standard Panel Size | 2440mm × 1220mm (4ft × 8ft) | Standard 4×8 ft; max width ≤3.2m, length ≤12m customizable |

| Fire Rating | Optional marine-grade flame retardant rating | Optional Class B1 or higher marine fire rating |

| Color | Standard white/gray; multiple colors available per customer requirements | Standard white/gray; RAL colors or custom available |

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.